Making method of ABS (Antilock Braking System) shell

A manufacturing method and a technology for a shell, which are applied to other household appliances, household appliances, applications, etc., can solve problems such as serious accuracy, waste of raw materials, and insufficient, and achieve the effect of saving raw materials and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] A method for manufacturing an ABS housing, comprising the following steps:

[0023] refer to figure 1 , A. using a punching machine to blank the blank into a round cake 1 with a diameter of 135mm;

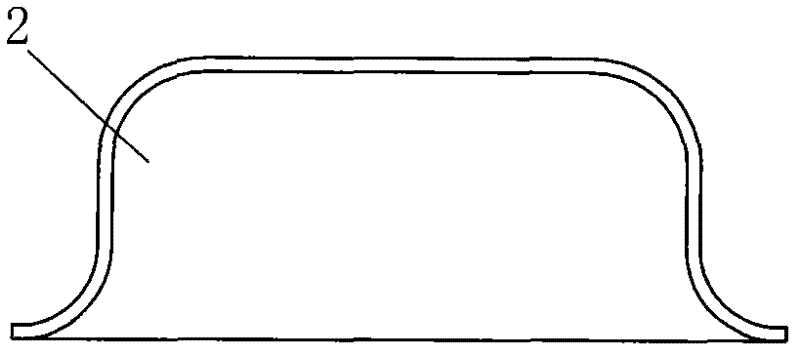

[0024] refer to figure 2 , B. adopt the punch press to punch out the first workpiece 2 on the mold, the first workpiece is cylindrical, and the bottom surface and the side of the cylindrical first workpiece are arc transitions, and the radius of the arc is 12mm; The opening end of the cylindrical head workpiece has an outwardly turned flanging, the diameter of the opening end is 74 mm, the cross section of the flanging is arc-shaped with a radius of 12 mm, and the height of the head workpiece is 35.6 mm;

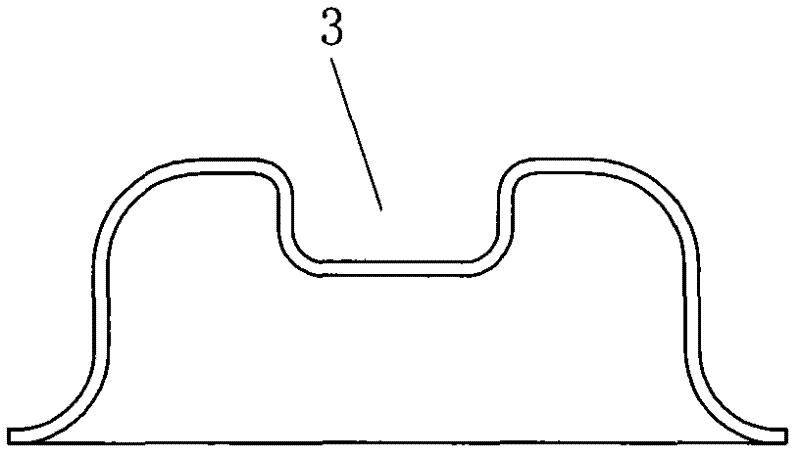

[0025] refer to image 3 , C. Punch out a 17mm deep columnar recessed groove 3 on the mold with a punching machine on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com