Reversing radar probe installing device with elastic sheet compensation structure

A technology of installation device and compensation structure, which is applied to vehicle parts, transportation and packaging, etc., can solve the problems of unsatisfactory appearance, difficult and unreliable radar installation, etc., and achieves the effect of simple structure, low cost and meeting structural requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical scheme and technical purpose of the present invention easier to understand, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

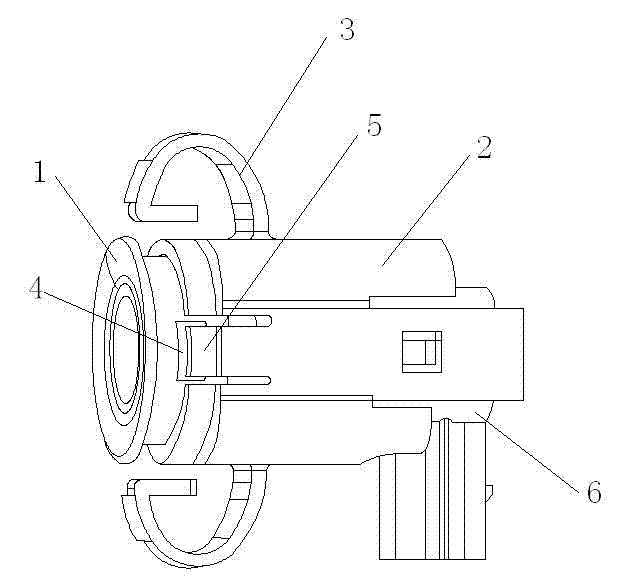

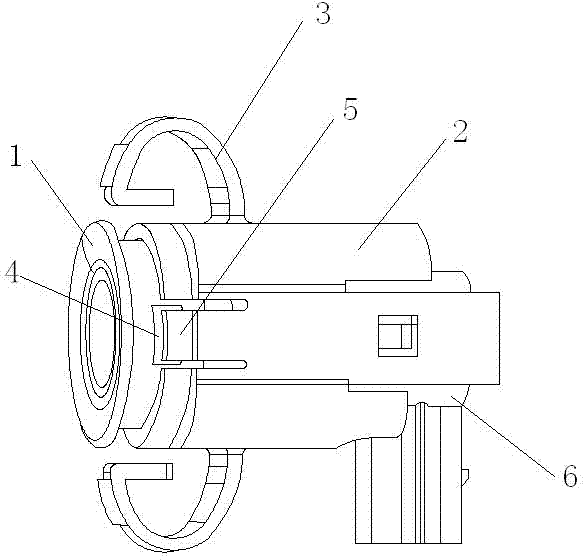

[0011] As shown in the figure, an installation device for a parking radar probe is provided with a G-shaped plastic shrapnel compensation structure. The installation device is composed of a front cover 1 and a sleeve-type rear bracket 2. The front cover 1 includes a front stand and a The clamping post connected to the front gear platform, the side of the clamping post is provided with a bayonet 4, and the side of the bracket 2 is provided with a tab 5 corresponding to the bayonet 4, and the front cover 1 and the rear support 2 are connected by snapping. Two G-shaped plastic shrapnels 3 are arranged on both sides of the rear bracket 2, and the bracket 2 and the shrapnels 3 are integrally formed by injection molding to save cost.

[0012] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com