Method of supplying liquid crystal to liquid crystal coater

A liquid crystal coating machine, liquid crystal technology, applied to the surface coating liquid device, coating, optics, etc., can solve the problem of long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

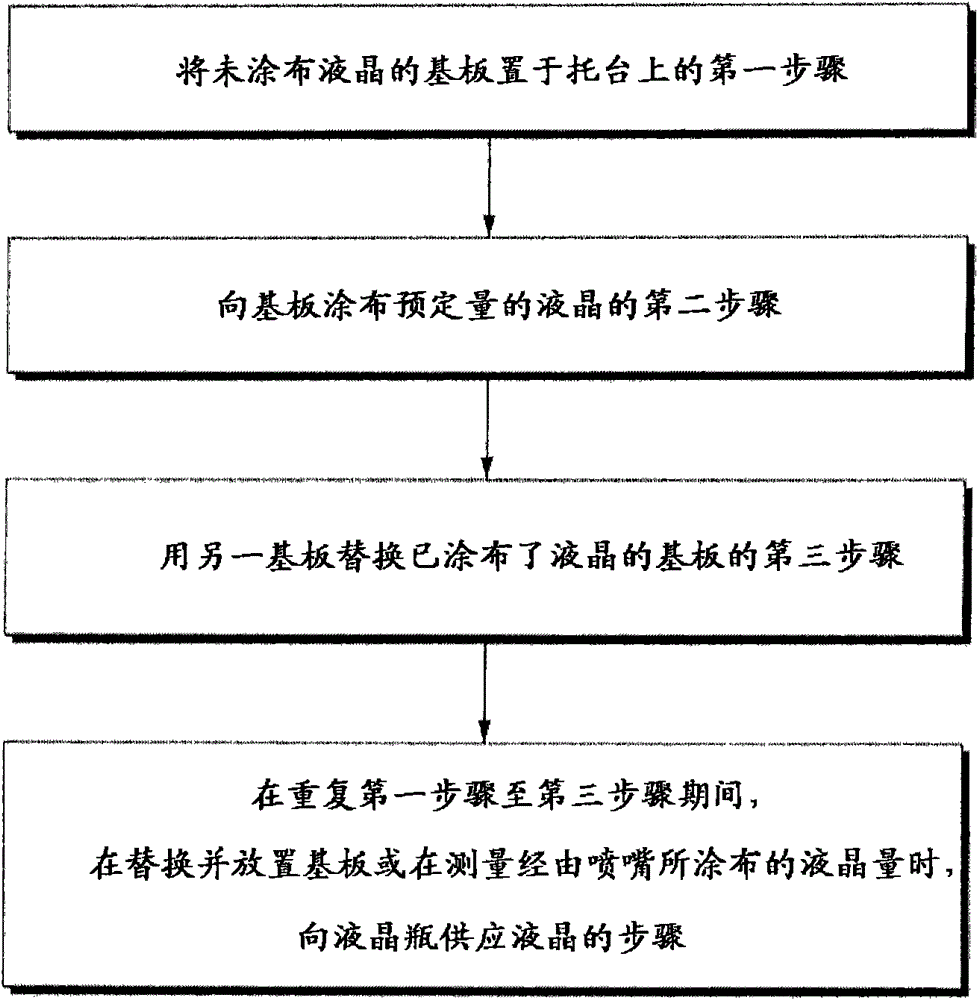

[0048] A method for supplying liquid crystals to a liquid crystal coating machine according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

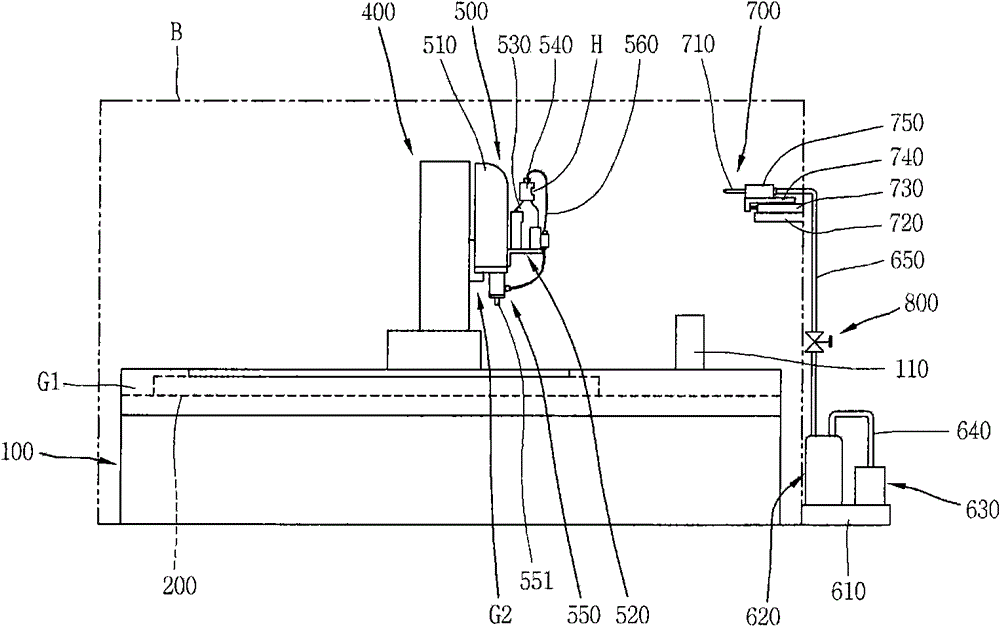

[0049] First combine the figure 1 The liquid crystal coater and the liquid crystal supply unit will be described.

[0050] A liquid crystal coater is installed, and then a clean booth B is installed to cover the liquid crystal coater. The liquid crystal supply unit is installed outside the clean room B.

[0051] The liquid crystal coating machine comprises: a main frame 100; a pallet 200, which is installed on the main frame 100; a first guide unit G1, which is connected to the main frame 100 in a manner located on both sides of the pallet 200; a coating head unit Support frame 400, it is coupled with the first guide unit G1; The first drive unit (not shown), its effect is to move coating head unit support frame 400; The second guide unit G2, it is arranged on coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com