Screw mounting device

An installation device and screw technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting production efficiency, inconvenient operation, easy to fall, etc., and achieve the effect of convenient production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

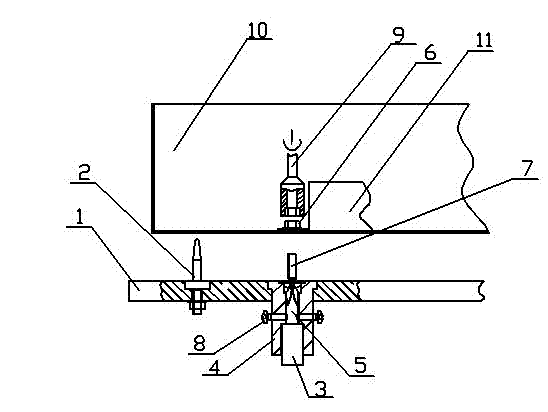

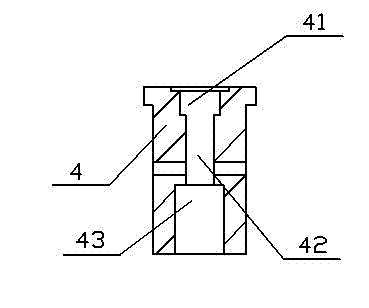

[0009] Such as figure 1 , 2 As shown, the screw installation device includes a base plate 1, a positioning nail 2, a strong magnetic steel 3, a fixing column 4, and a screwdriver 5, and a plurality of fixing columns 4 are arranged at the bottom of the base plate 1; the upper part of the fixing column 4 is provided with a cavity 41, and the center There is a through hole 42, and the lower part is provided with a blind hole 43; the screwdriver 5 is placed in the through hole 42, fixed with a screw 8 from both sides, and the strong magnetic steel 3 is placed in the blind hole 43; Locating nail 2, fixed with nuts;

[0010] The cross-sectional diameter of the cavity 41 is slightly larger than the diameter of the screw cap, and the axial height of the cavity 41 is equal to the height of the screw cap, so that the screw cap is completely sunk in the cavity 41. The screw cap is placed in the cavity 41 .

[0011] The diameter of the blind hole 43 is greater than the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com