Sealing furnace door structure

A furnace door and furnace body technology, which is applied in the field of sealing furnace door structures, can solve problems such as poor furnace door sealing, and achieve the effects of avoiding poor furnace door sealing problems, stable and reliable operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

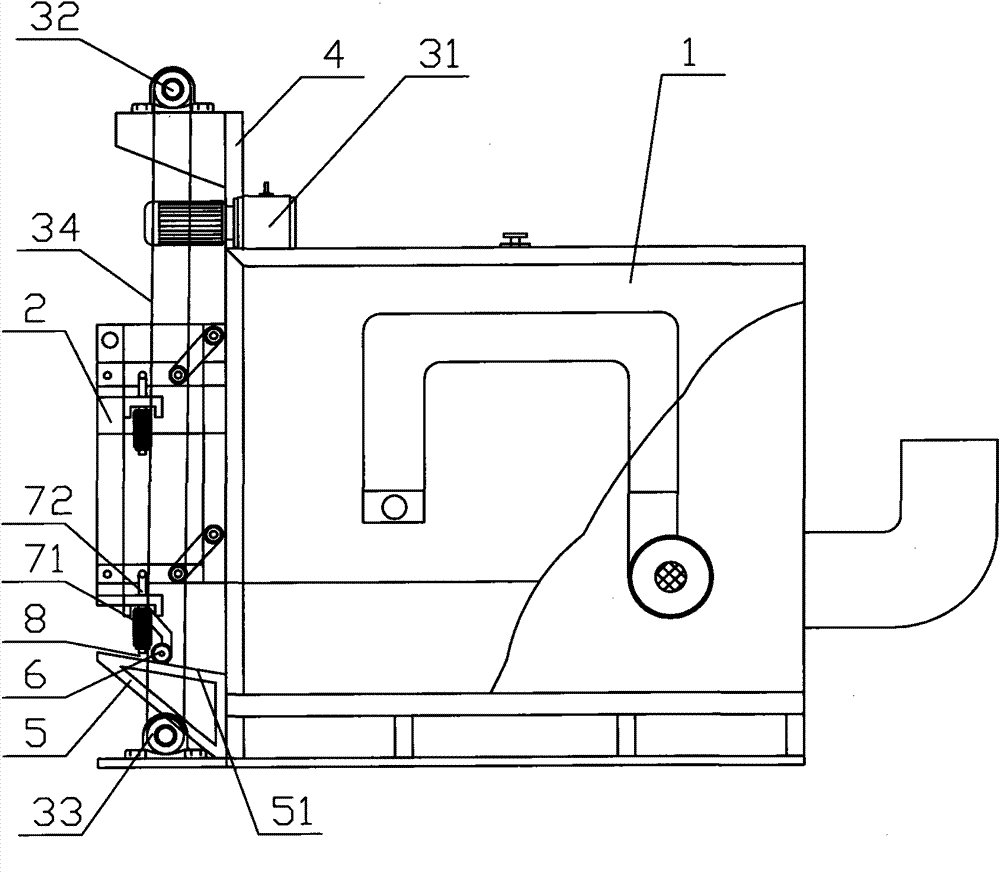

[0011] Such as figure 1 As shown, it is a sealed furnace door structure of the present invention, including a furnace body 1 and a furnace door 2 located at the port of the furnace body 1. The port of the furnace body is provided with a lifting mechanism for controlling the furnace door to move up and down. The lifting mechanism of the present invention is as follows: The furnace door rolling machine 31 shown in the figure, the upper roller 32, the lower roller 33 and the steel wire rope 34 are composed of a furnace door guide rail 4 on both sides of the port of the furnace body. The cooperation between the furnace door and the guide rail adopts a known common structure. This will not be described in detail. The furnace body below the furnace door is also provided with a furnace door base 5, the upper end of the furnace door base is provided with an inclined end face 51 that is high on the outside and low on the inside, and a roller 6 that cooperates with the inclined end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com