Electric maschine in a high protection category with improved rotor cooling

A technology of rotors and rotor shafts, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., to solve problems such as poor receiving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

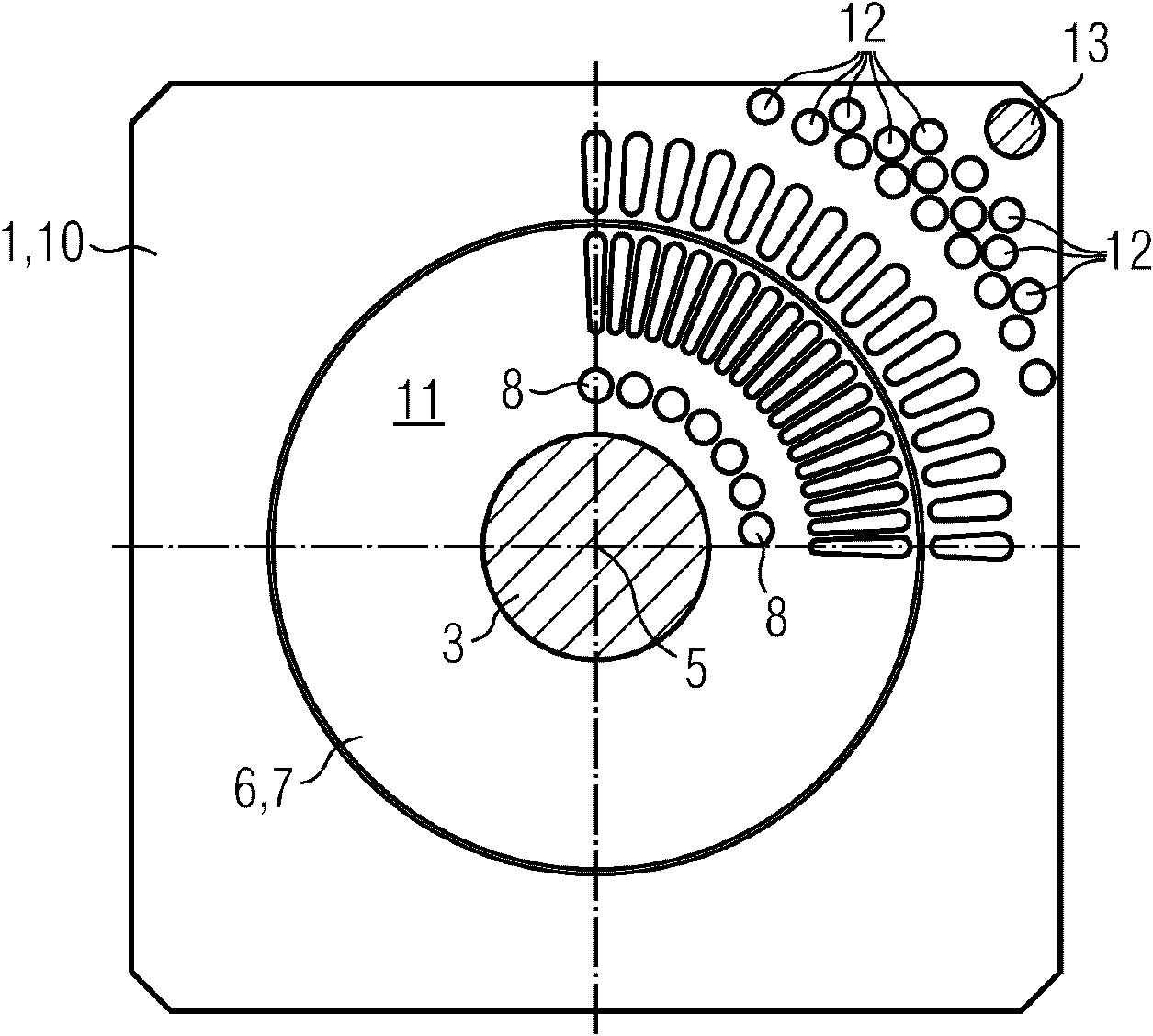

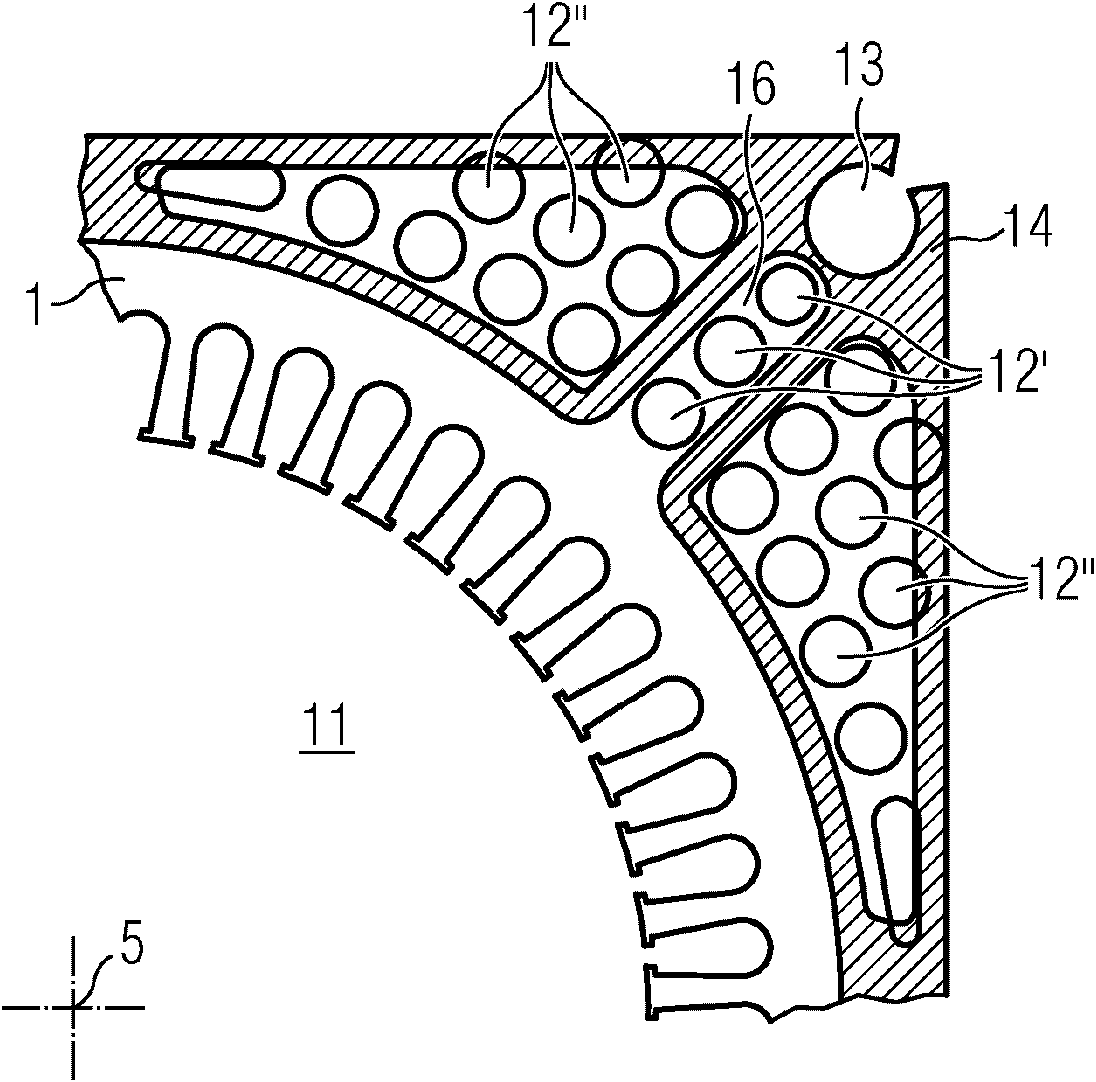

[0034] figure 1 and figure 2 The shown electric machine has a stator 1 . The stator 1 carries a stator winding 2 .

[0035] This electric machine also has a rotor shaft 3 . The rotor shaft 3 is mounted in a rotor shaft bearing 4 . As a result of being mounted in rotor shaft bearings 4 , rotor shaft 3 is rotatable about axis 5 relative to stator 1 .

[0036] Axis 5 can define axial, radial and tangential directions. Wherein, “axial” refers to a direction parallel to the axis 5 . “Radial” refers to the direction perpendicular to the axial direction, including two situations of facing the axis 5 and away from the axis 5 . “Tangential” refers to a direction that is perpendicular to both the axial direction and the radial direction, that is, a direction that surrounds the axis 5 and is separated from the axis 5 by a certain radial distance.

[0037] A rotor 6 is arranged on the rotor shaft 3 . The rotor 6 interacts electrically with the stator 1 . For example, the rotor 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com