Gasoline power spraying machine capable of being automatically controlled

An automatic control, gasoline engine technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of not easy to start and close the gasoline engine, damage to the pressure pump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

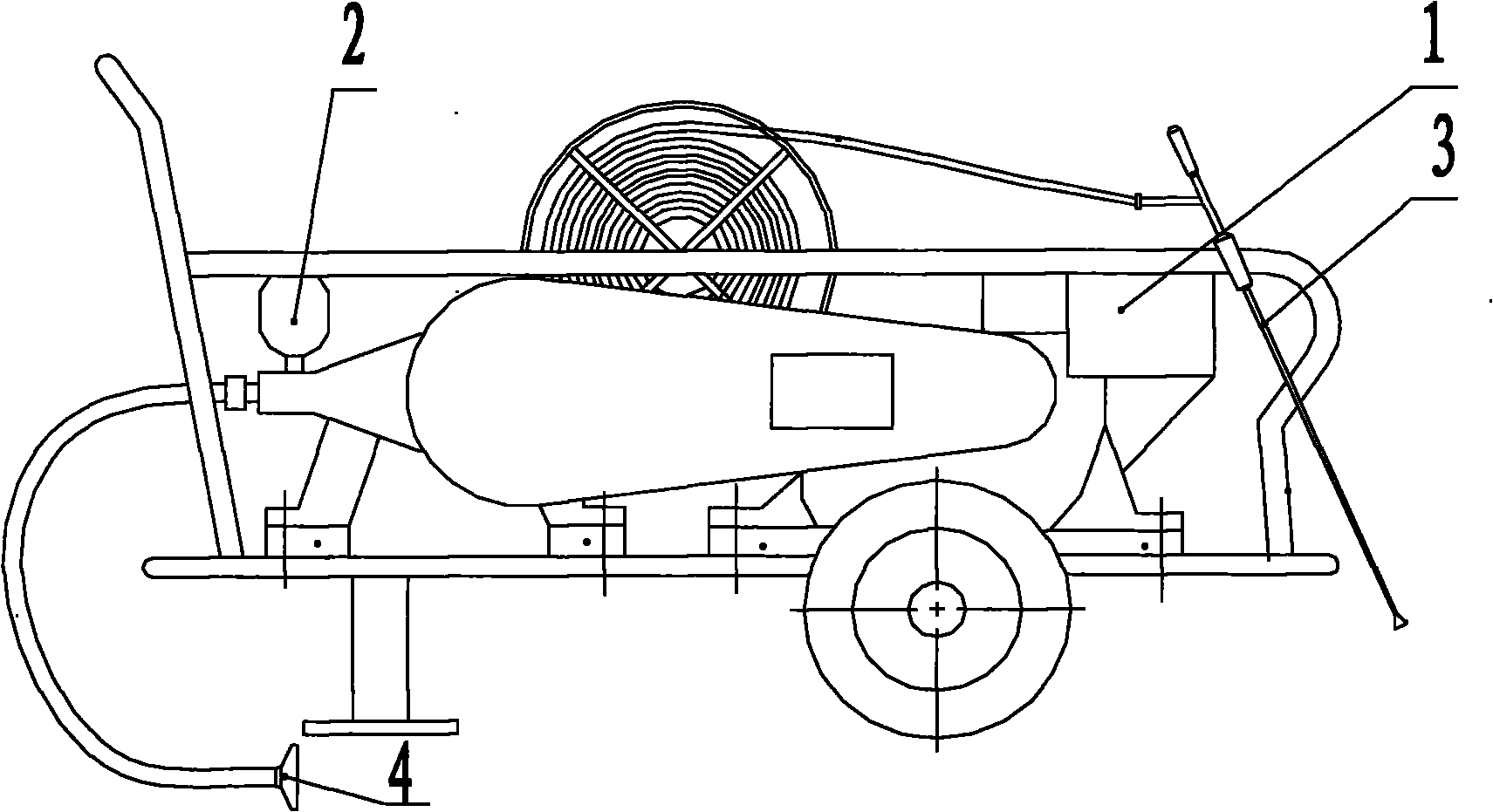

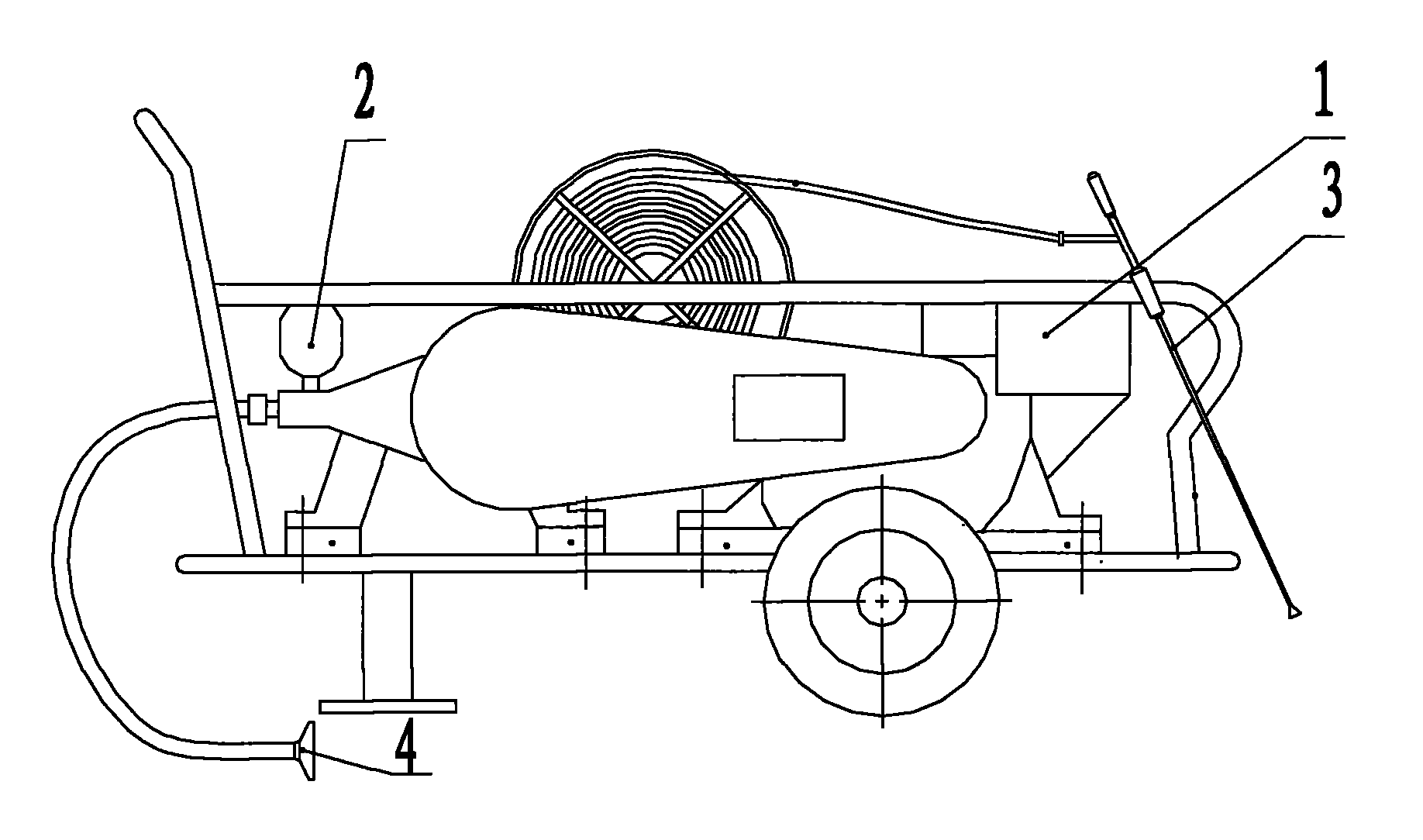

[0008] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

[0009] As shown in the accompanying drawings, a gasoline-powered sprayer that can be automatically controlled includes a gasoline engine 1, a pressure pump 2 and a spray gun part 3. The pressure pump 2 is driven by the gasoline engine 1, and the pressure pump 2 communicates with the spray gun part 3. The sprayer is provided with a control part for automatically starting and shutting down the gasoline engine, and the control part is to set a pressure sensor in the pressure pump 2, and the pressure sensor is connected with the ignition relay of the gasoline engine 1.

[0010] The working principle is: a pressure sensor is installed in the pressure pump 2, the pressure sensor is connected with the ignition relay of the gasoline engine 1, the gasoline engine 1 is started, and the gasoline engine 1 drives the pressure pump 2 to operate to generate pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com