Current lead wire system for superconducting magnet

A technology of superconducting magnets and current leads, applied in the field of lead systems, can solve the problems of increased thermal resistance of insulating gaskets, unreliable cooling, broken insulating gaskets and heat-conducting parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

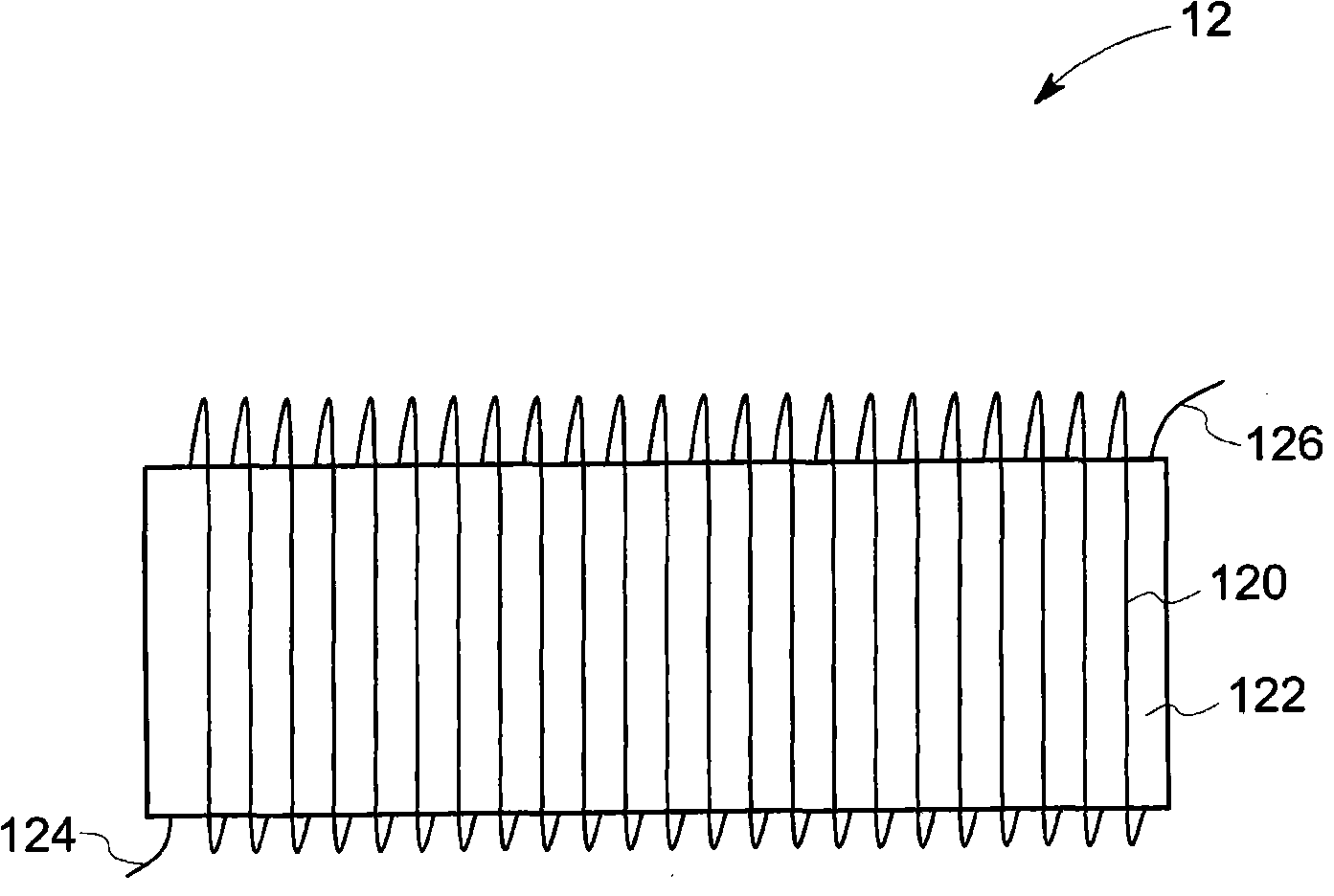

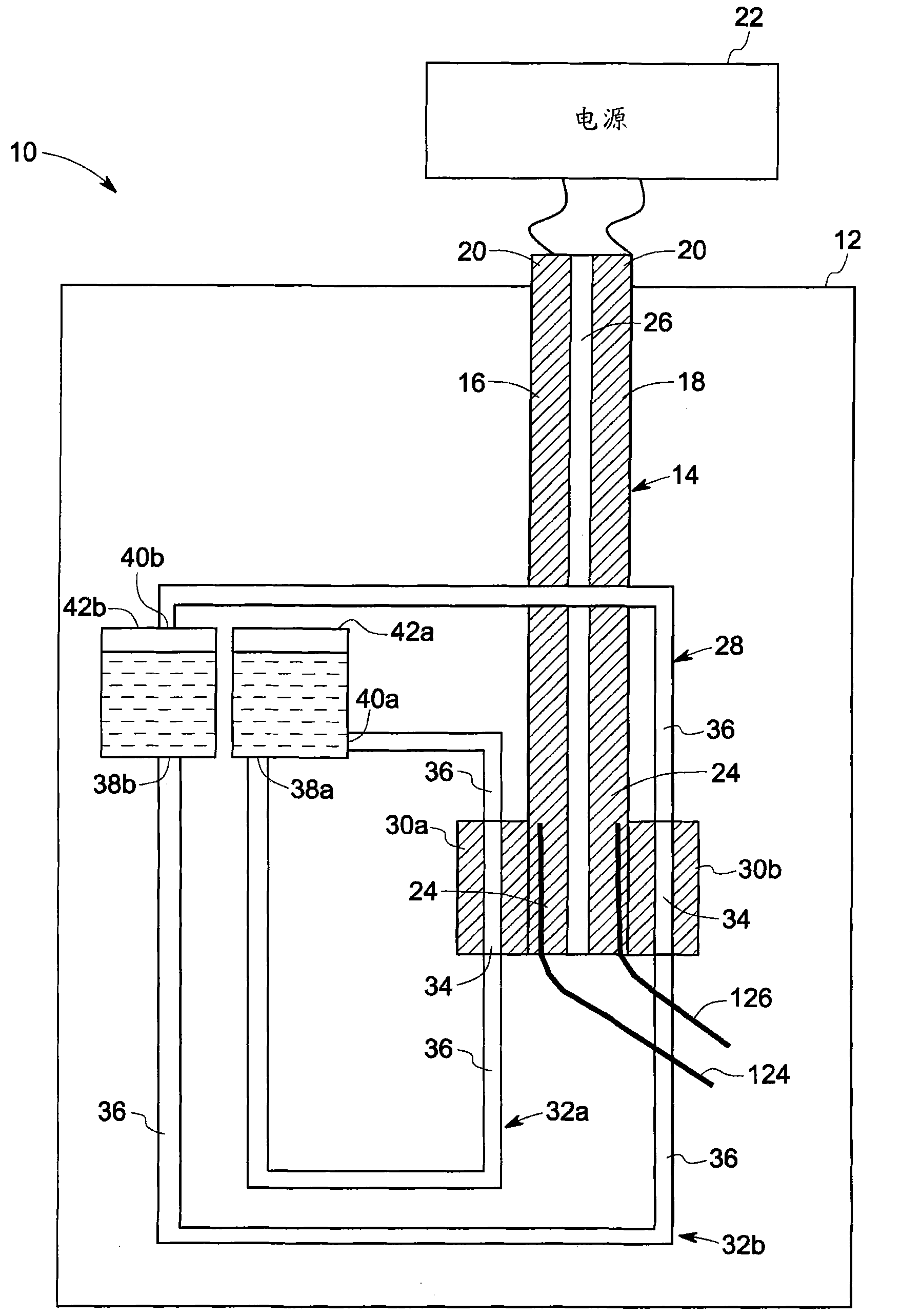

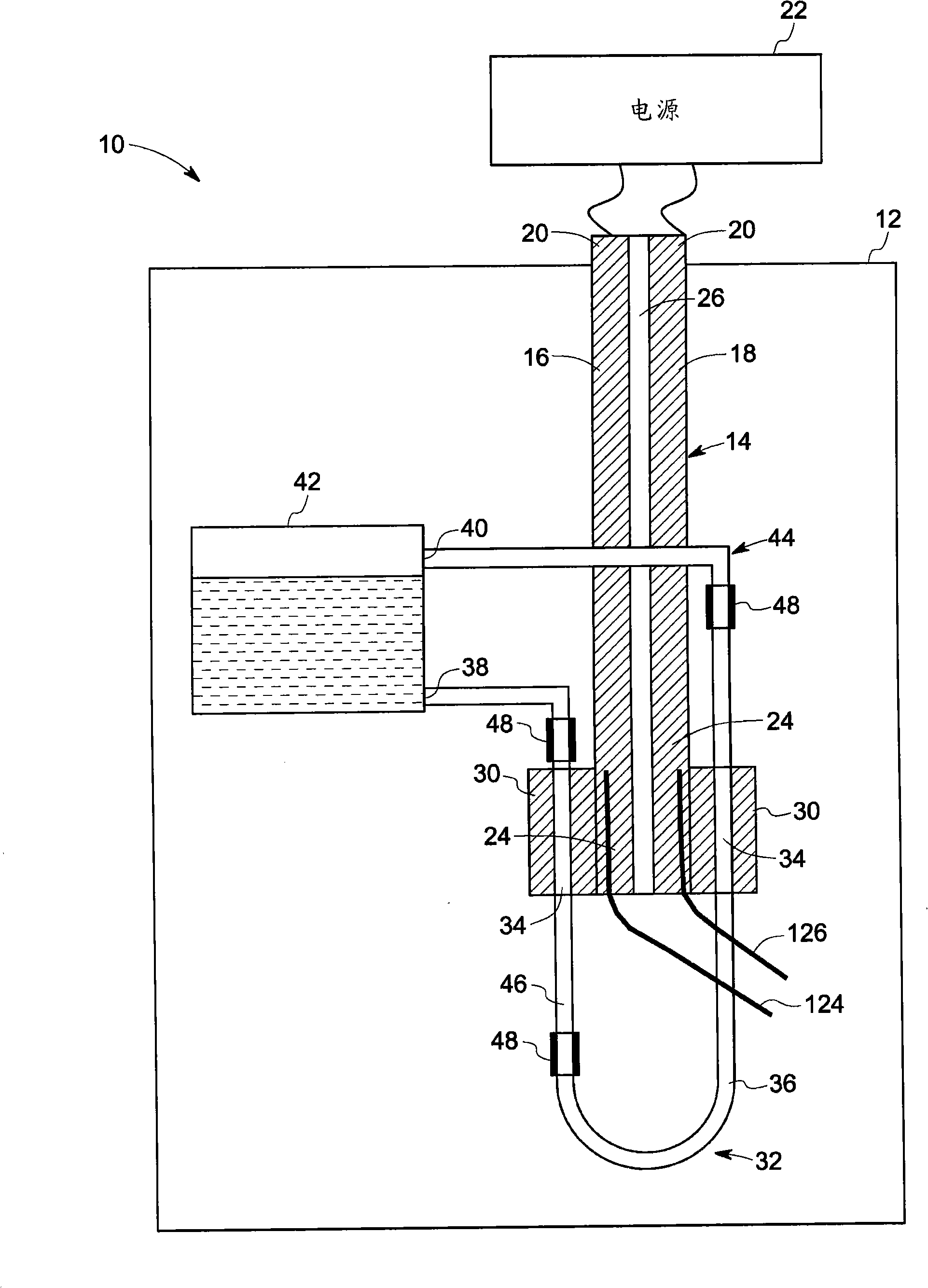

[0014] Several embodiments of the invention relate to superconducting magnet lead wire systems. The lead system includes a positive current lead, a negative current lead, and a cryogenic refrigeration system. The positive and negative current leads each have one end electrically connected to a power supply (hereinafter referred to as "hot end"), and the other end electrically connected to the superconducting magnet (hereinafter referred to as "cold end"). The cryogenic refrigeration system includes a thermally conductive element thermally coupled to the cold end of the conductive wire, and a coolant channel passing through the thermally conductive element. A liquid coolant flows through the coolant channel, absorbs heat from the cold end of the conductive wire, and evaporates into a gas to carry away the heat, thereby keeping the cold end of the conductive wire at a low temperature without transferring heat to the superconducting magnet. The current is transmitted to the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com