Fully-printed electronic and PCB (printed circuit board) ink-jet print apparatus

A technology of inkjet printing equipment and inkjet printing device, which is applied in the field of fully printed electronics and circuit board inkjet printing equipment, to achieve the effect of less time, short printing track and increased friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

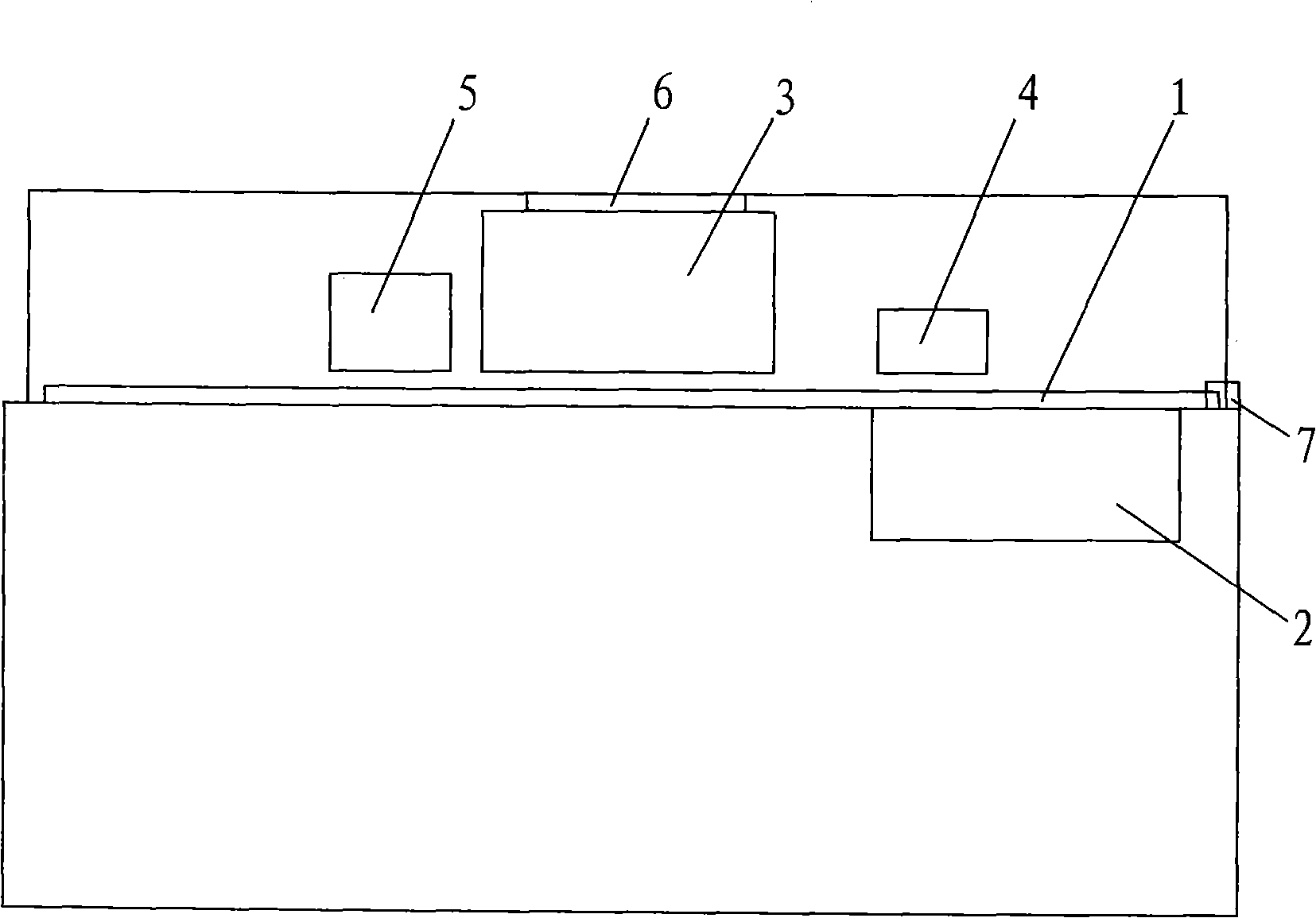

[0021] Below in conjunction with accompanying drawing, the present invention will be further described, see figure 1 , fully printed electronic and circuit board inkjet printing equipment, which includes a control system, a conveying device 1 for conveying electronic components or circuit boards, a driving device 2 for driving the conveying device 1, and an inkjet printing device arranged above the conveying device 1 Device 3, the control system can be controlled by computer, or by CPU, single-chip microcomputer, PLC, etc. The conveying device 1 can be a conveyor belt, the driving device 2 can be a servo motor, and the servo motor can be driven by a reducer, a gear transmission mechanism, or a chain. Mechanism, pulley transmission mechanism, etc. drive the conveying device 1 to move, and the circuit board can be transported after being placed on the conveying device 1. An image positioning device 4 that can automatically obtain the circuit board image and adjust the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com