Explosion-proof and bulletproof inflation-free tyre

A technology of pneumatic tires and non-pneumatic inner tubes, applied in non-pneumatic tires, special tires, tire parts, etc., can solve the problems of poor heat dissipation, poor elasticity, large holes, etc., and achieve the effect of safe and reliable use and good comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] Example 1:

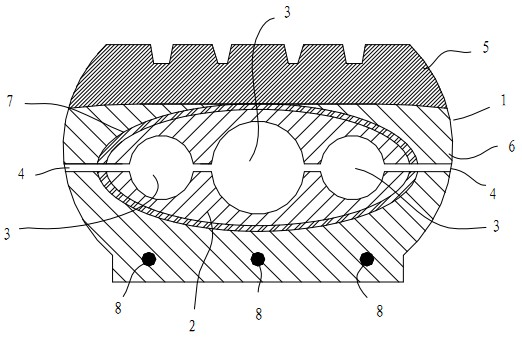

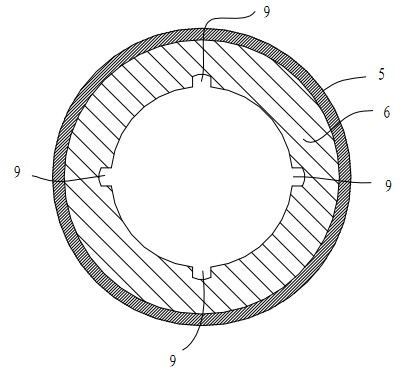

[0015] See figure 1 , Is a schematic diagram of the upper cross-sectional structure of the explosion-proof, bullet-proof, non-pneumatic tire of the present invention, which is composed of a tire 1 and a non-pneumatic inner tube 2 with three horizontally arranged cavities 3. The cross-section of the non-pneumatic inner tube 2 is olive-shaped. The tire 1 is composed of a tread 5 made of non-foamed nano-polyurethane rubber and a carcass 6 made of foamed nano-polyurethane rubber. The two opposite sides of the carcass 6 are respectively provided with heat dissipation holes 4 communicating with the cavity 3. A radial cord 7 is provided between the inner tube 2 and the inner tube 2. Two beads 8 are provided in the carcass 6. Four grooves 9 are provided on the inner edge of the casing 1.

[0016] When preparing the tire of Example 1, rubber or reclaimed rubber with low internal heat generation and good stability is first selected to make a non-inflatable inner tube 2 ...

Example Embodiment

[0021] Example 2:

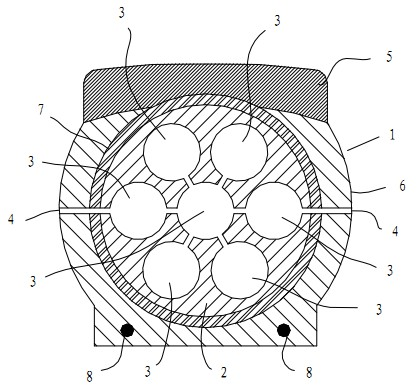

[0022] Refer to image 3 , Is a schematic diagram of the upper cross-sectional structure of another explosion-proof, bullet-proof, non-pneumatic tire of the present invention, which is composed of a tire 1 and an inflatable inner tube 2 with a cavity 3, wherein the inflatable inner tube 2 has seven communicating cavities 3, and the cavity 3 constitute a honeycomb structure, the cross section of the non-inflatable inner tube 2 is circular. The tire 1 is composed of a tread 5 made of non-foamed nano-polyurethane rubber and a carcass 6 made of foamed nano-polyurethane rubber. The two opposite sides of the carcass 6 are respectively provided with heat dissipation holes 4 communicating with the cavities 3 on the left and right sides. A radial cord 7 is provided between the outer tire 1 and the non-inflated inner tire 2. Two beads 8 are provided in the carcass 6. Other technical features are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap