Cathode rod suspension arm mechanism

A technology of cathode rods and booms, which is applied to cranes and other directions, can solve the problems of difficulty in guaranteeing manufacturing accuracy and strength, high manual processing costs, and large material loss, and achieve the effects of improving precision, saving costs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

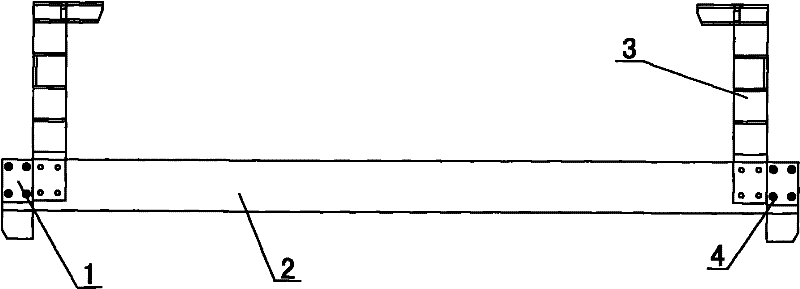

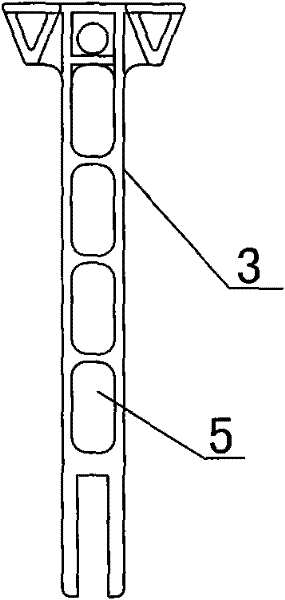

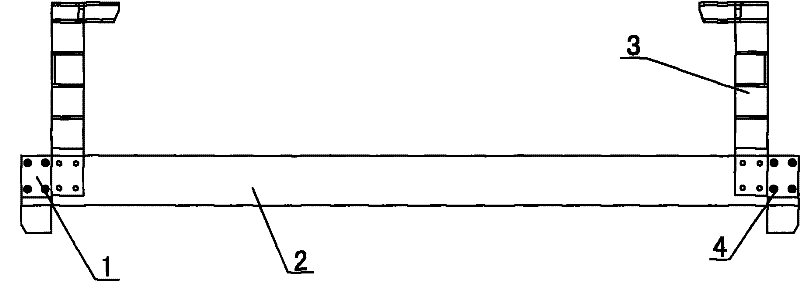

[0012] Such as Figure 1-2 As shown, the cathode rod boom mechanism of the present invention includes a conductive rod 2 and a boom 3, the two ends of the conductive rod 2 are provided with a conductive head 1 and connected through a positioning hole 4, and the two sides of the conductive rod 2 are respectively vertical A boom 3 is installed, and several arm holes 5 are provided on the boom 3; the boom 3 is an integral casting structure, which can save costs and improve precision. The accuracy of the positioning of the mobile cathode rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com