Fuel pump and its brushless motor assembly

A brushless motor and fuel pump technology, which is applied to electric components, pump components, electrical components, etc., can solve problems such as large vibration and increase the difficulty of assembly, and achieve the effects of low vibration, simplified assembly work, and collision avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings.

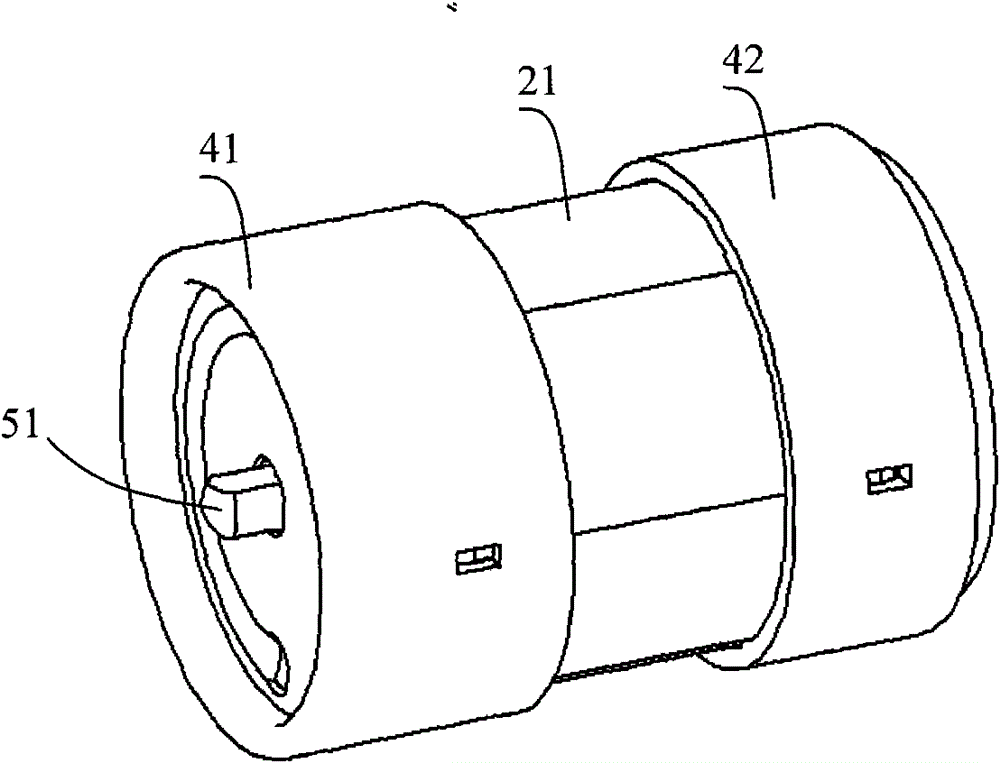

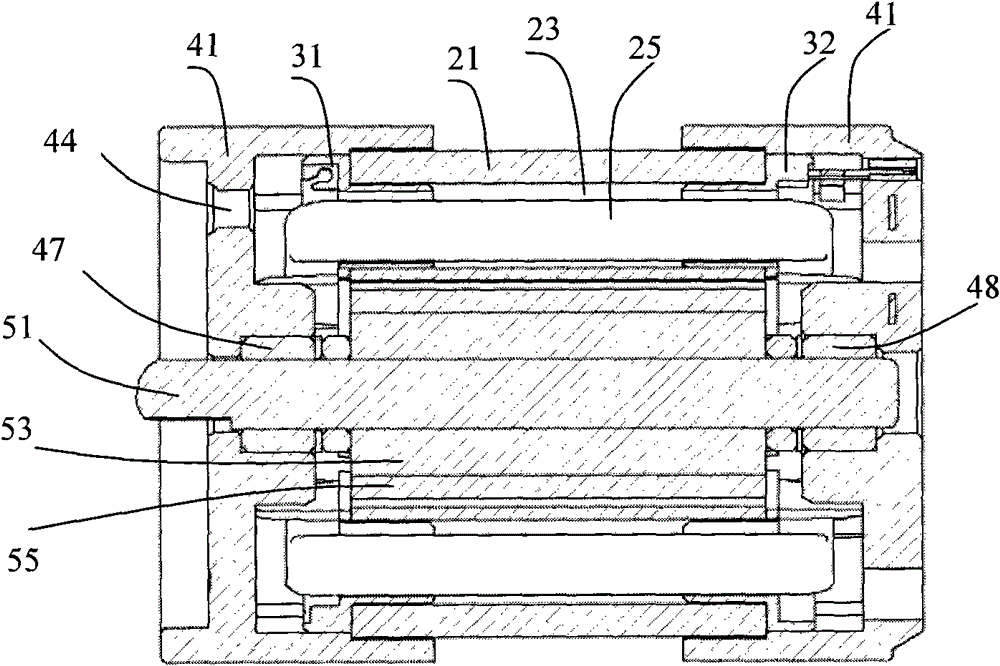

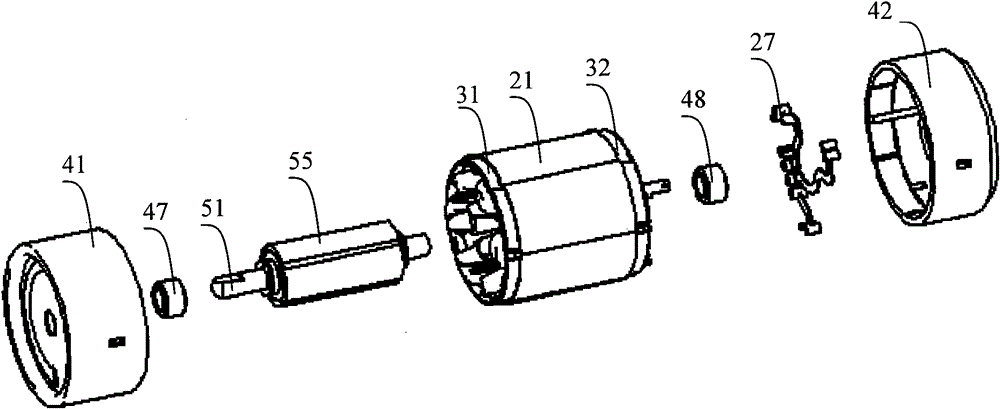

[0024] figure 1 It is a schematic diagram of a fuel pump brushless motor assembly provided by an embodiment of the present invention, figure 2 and image 3 Respectively, the sectional view and the expanded schematic diagram of the brushless motor assembly. The motor assembly includes a stator, a rotor and two plastic fixing covers 41 and 42 . The stator includes a stator core 21 , a winding 25 , a terminal 27 and insulating wire frames 31 and 32 . The stator core has inwardly protruding teeth 23 onto which windings 25 are wound. Insulating wire frames 31 and 32 are installed from both ends of the stator core 21 respectively, covering the axial end faces of the teeth 23 and at least part of the surface of the coil slots, so as to insulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com