Multi-purpose hoister for engineering installation

A hoist and engineering technology, applied in the direction of hoisting devices, etc., can solve the problems of unstable operation, difficulty in ensuring multi-point and multi-equipment synchronization, inconvenient installation and fixing of hoisting equipment, etc., and achieve the effect of stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

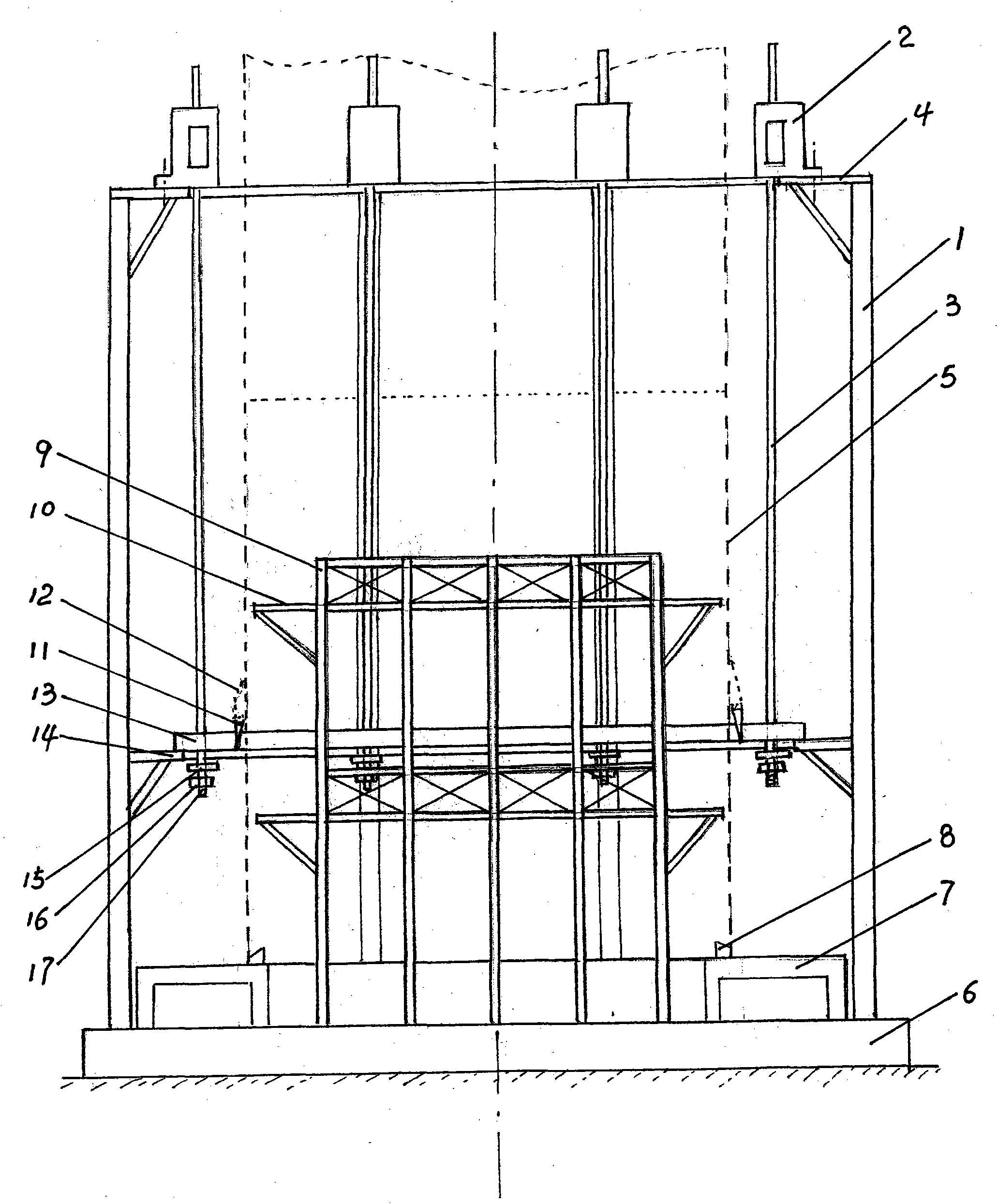

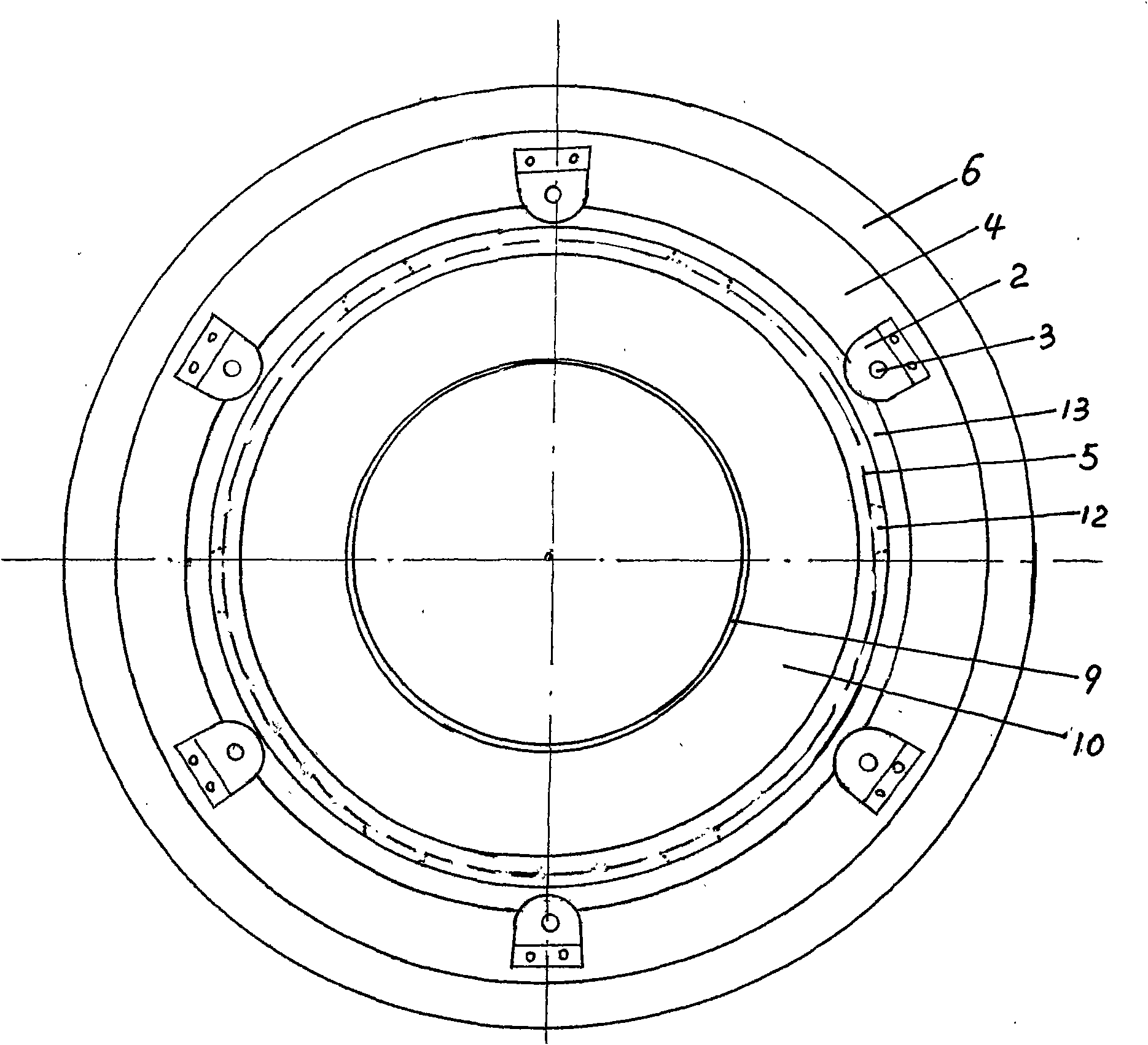

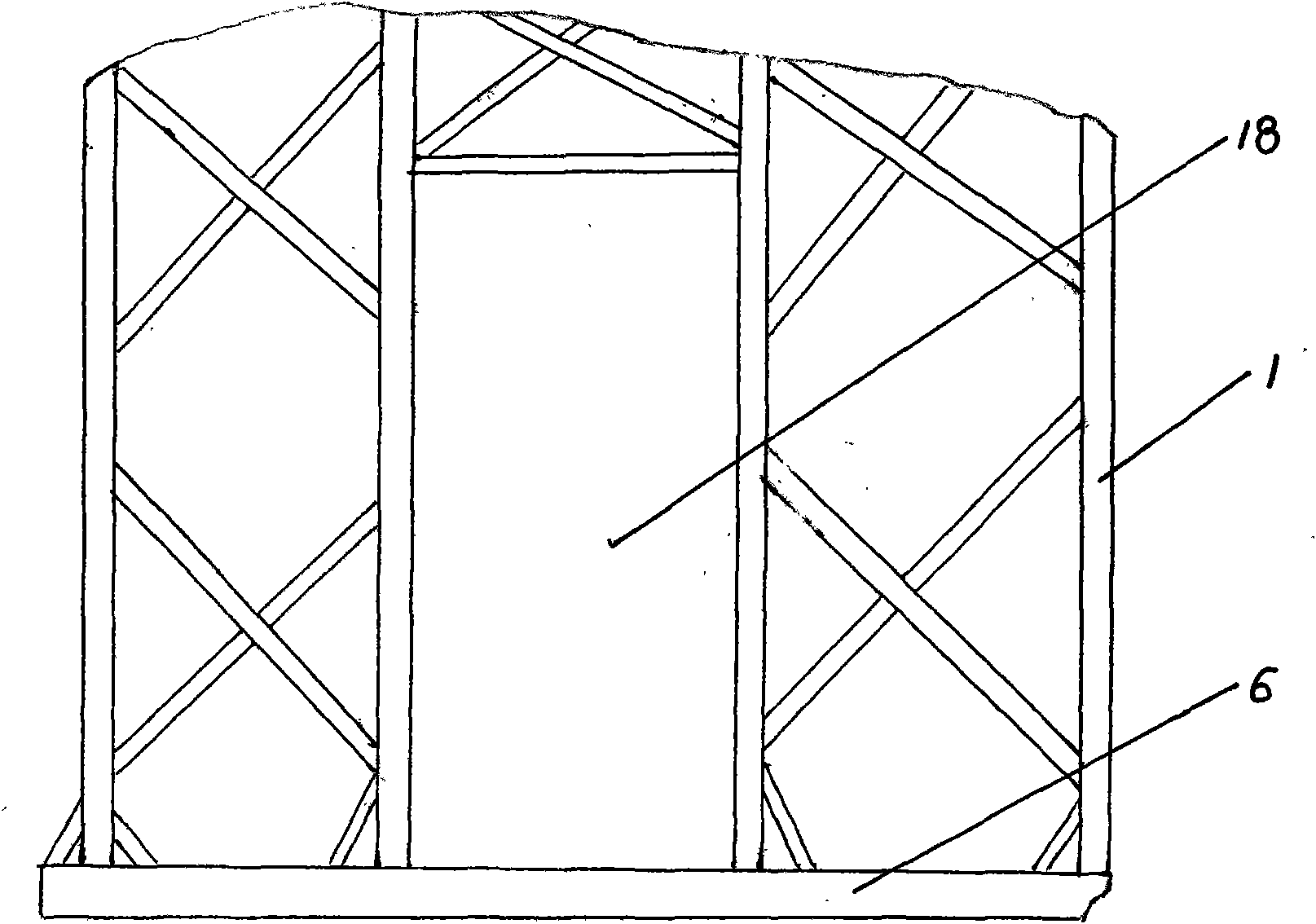

[0029] figure 1 , 2 , 3, 6, 7, 8: The multi-purpose hoist for engineering installation is mainly composed of steel frame body 1, hydraulic hoist 2, hoisting rod 3, and base platform 6. A vertically arranged steel frame body 1 is fixed on the base platform 6. The steel frame body 1 is a ring-shaped rigid frame body in the shape of a fence, and a vertically arranged work platform steel frame body 9 is fixed on the base platform 6 , The work platform steel frame body 9 is a ring-shaped rigid frame body in the shape of a fence, the steel frame body 1 and the work platform steel frame body 9 have the same ring-shaped fence shape, and the steel frame body 1 and the work platform steel Between the frame bodies 9 is an annular working chamber. A lifter fixing platform 4 is provided on the top of the steel frame body 1 at the upper part of the working chamber, and 6 hydraulic lifts are uniformly installed and fixed on the lifter fixing platform 4 The hoop positioning frame 14 is horizon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap