Method for refining metal solidification structure by using pulsed magnet field and pulse current with same frequency

A pulsed magnetic field and pulsed current technology, applied in the field of metal solidification control, can solve the problems of poor refinement effect, high external field energy consumption, uneven solidification structure, etc., and achieve the effects of increased effect, energy saving, and significant technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

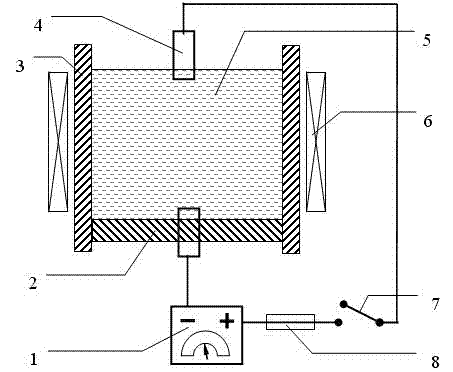

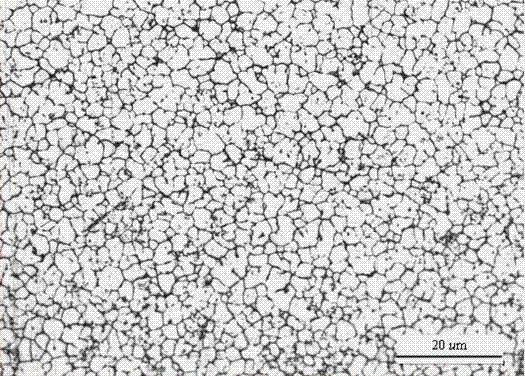

[0039] Example 1: The same frequency pulsed magnetic field and pulsed current control the solidification structure of pure aluminum in the graphite mold

[0040] The experimental process is as follows:

[0041] Melt preparation: Melt 1kg (99.7%) of industrial pure aluminum at 720°C;

[0042] Mold: Electrode graphite mold, baked to 400°C, the size of the graphite mold is Φ160×150mm, a tungsten electrode is placed in the center of the bottom of the graphite mold, and a corundum tube is used to insulate the tungsten electrode from the mold. Before the graphite mold is used Insert the bottom electrode;

[0043] Solidification process: After the aluminum melt is degassed and the temperature drops to 700 ° C, it is poured into the graphite mold, another tungsten electrode is inserted into the melt, and then the pulse magnetic field is turned on and the pulse current power supply is turned on to adjust the pulse magnetic field. The parameters are: pulse width is 10 mu s, the act...

Embodiment 2

[0045] Example 2: Continuous casting and solidification of refined pure aluminum in a water-cooled copper crystallizer with the same frequency pulsed magnetic field and pulsed current

[0046] The experimental process is as follows:

[0047] Melt preparation: Melt 500kg (99.7%) of industrial pure aluminum at 720°C;

[0048] Copper crystallizer: The size of the continuous casting crystallizer is Φ280×250mm. The bottom electrode is placed on the dummy rod. The electrode and the dummy rod are insulated with a corundum tube. The bottom electrode is installed before pouring;

[0049] Solidification process: After the aluminum melt is degassed, when the temperature drops to 710°C, it is poured into the crystallizer and the semi-continuous casting dummy casting is started at the same time. The casting speed is 0.2m / min. When the liquid level in the crystallizer is stable Finally, insert another tungsten electrode into the melt, and then turn on the pulse magnetic field and connect...

Embodiment 3

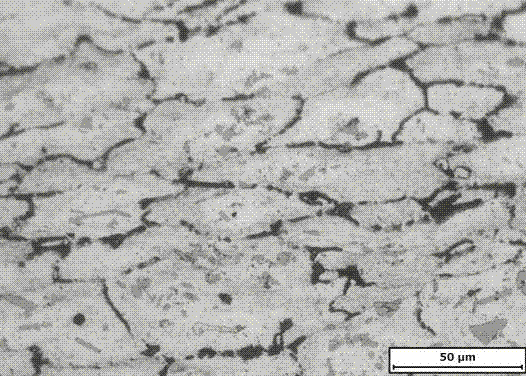

[0051] Example 3: Semi-continuous casting and solidification of pure copper refined by the same frequency pulsed magnetic field and pulsed current in a water-cooled stainless steel crystallizer

[0052] The experimental process is as follows:

[0053] Melt preparation: 150kg (99.9%) of industrial pure copper is smelted at 1200°C;

[0054] Copper crystallizer: The size of the continuous casting crystallizer is Φ280×250mm. The bottom electrode is placed on the stainless steel dummy rod. The electrode and the dummy rod are insulated with a corundum tube. The bottom electrode is installed before pouring;

[0055] Solidification process: After the copper melt is degassed, when the temperature drops to 1150°C, it is poured into the crystallizer and the semi-continuous casting dummy casting is started at the same time. The casting speed is 0.5m / min. When the liquid level in the crystallizer is stable Finally, insert another tungsten electrode into the melt, then turn on the pulsed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com