Catalyst thin layer and method for fabricating the same

A catalyst and thin layer technology, applied in the field of catalyst thin layer and its manufacture, can solve the problems of difficult access to catalytic sites and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

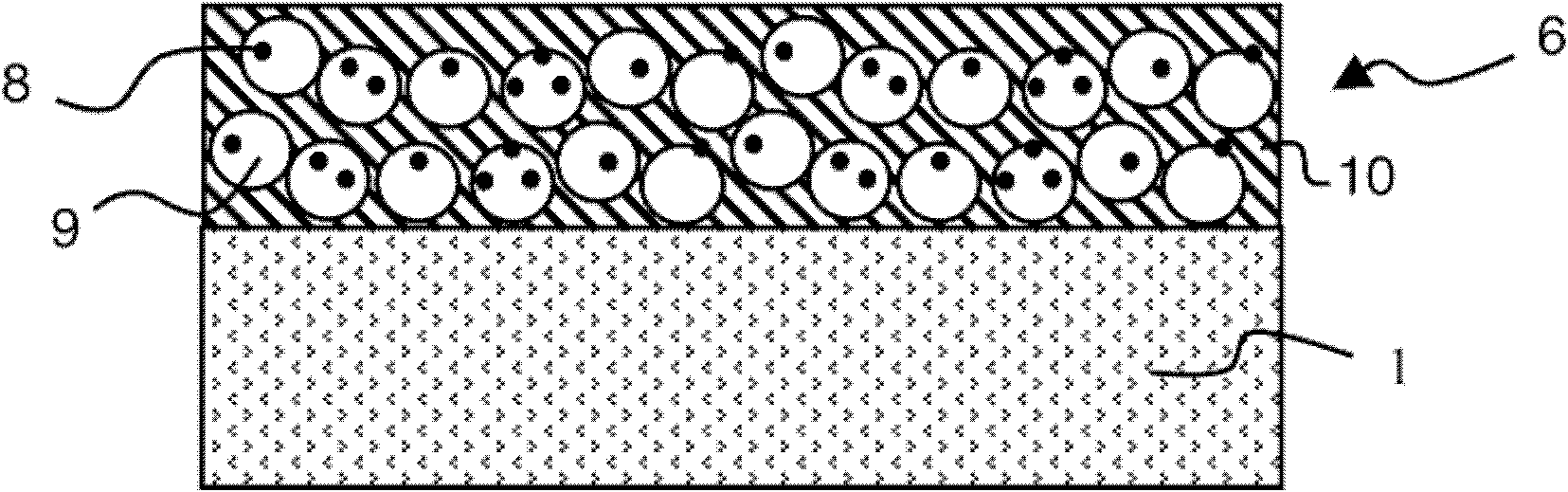

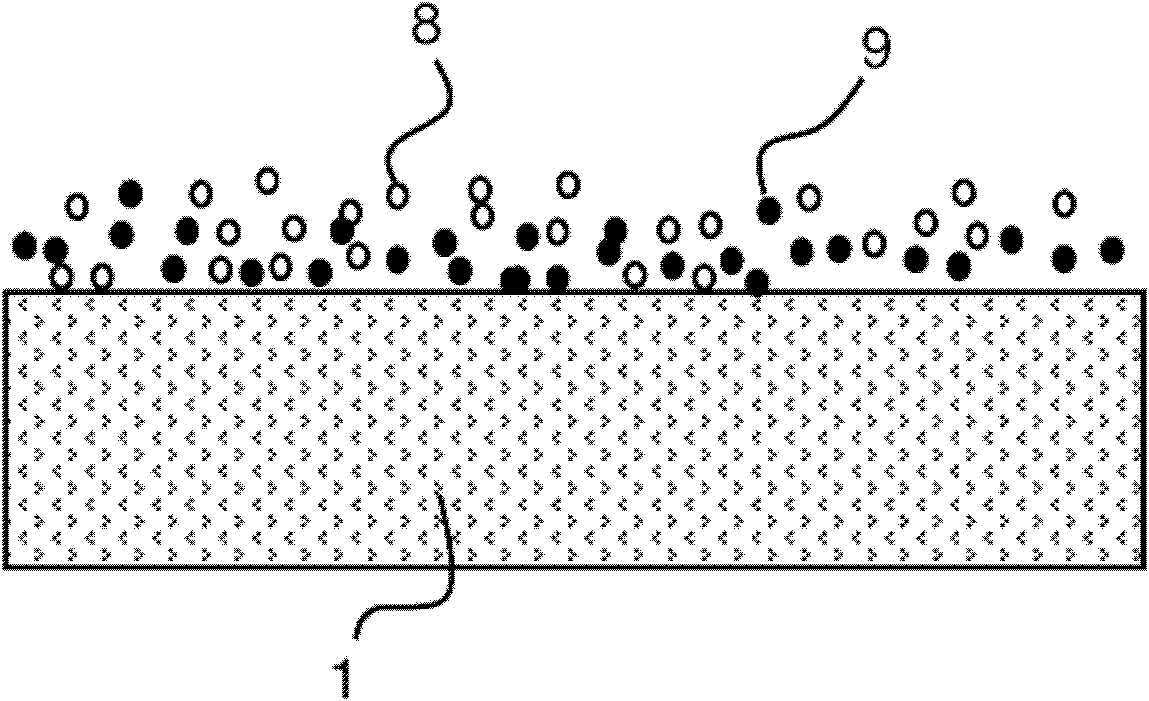

[0021] refer to Figure 4 , the thin catalyst layer 11 consists of electronically conductive catalyst nanoparticles 12 embedded in a polymer matrix 13 . The thin catalyst layer 11 has a preferred thickness of less than or equal to 2 μm. Catalyst nanoparticles 12 are embedded in said polymer matrix 13 without any other support and electron conduction is ensured in the catalyst layer 11 by a percolation mechanism. The exclusion of carbon particles 9 according to the prior art enhances electron conduction, since catalyst nanoparticles 12 are more electrically conductive than carbon particles 9 . However, at low catalyst atomic percentages, ie, when the ratio of catalyst atoms / total number of atoms is low, the electronically conductive catalyst nanoparticles 12 are dispersed in the polymer matrix 13 . They are too far apart from each other to be reached by electrons provided, for example, by electrochemical reactions. On the other hand, at high catalyst atomic percentages, elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com