Liquid evaporator with ultrasonic atomization and temperature control functions

A technology of ultrasonic atomization and temperature control, which is applied in the direction of liquid injection device, spray evaporation, injection device, etc., to achieve the effect of increasing the flow path, precise temperature control, and increasing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] The present invention will be further described below with reference to the drawings and embodiments.

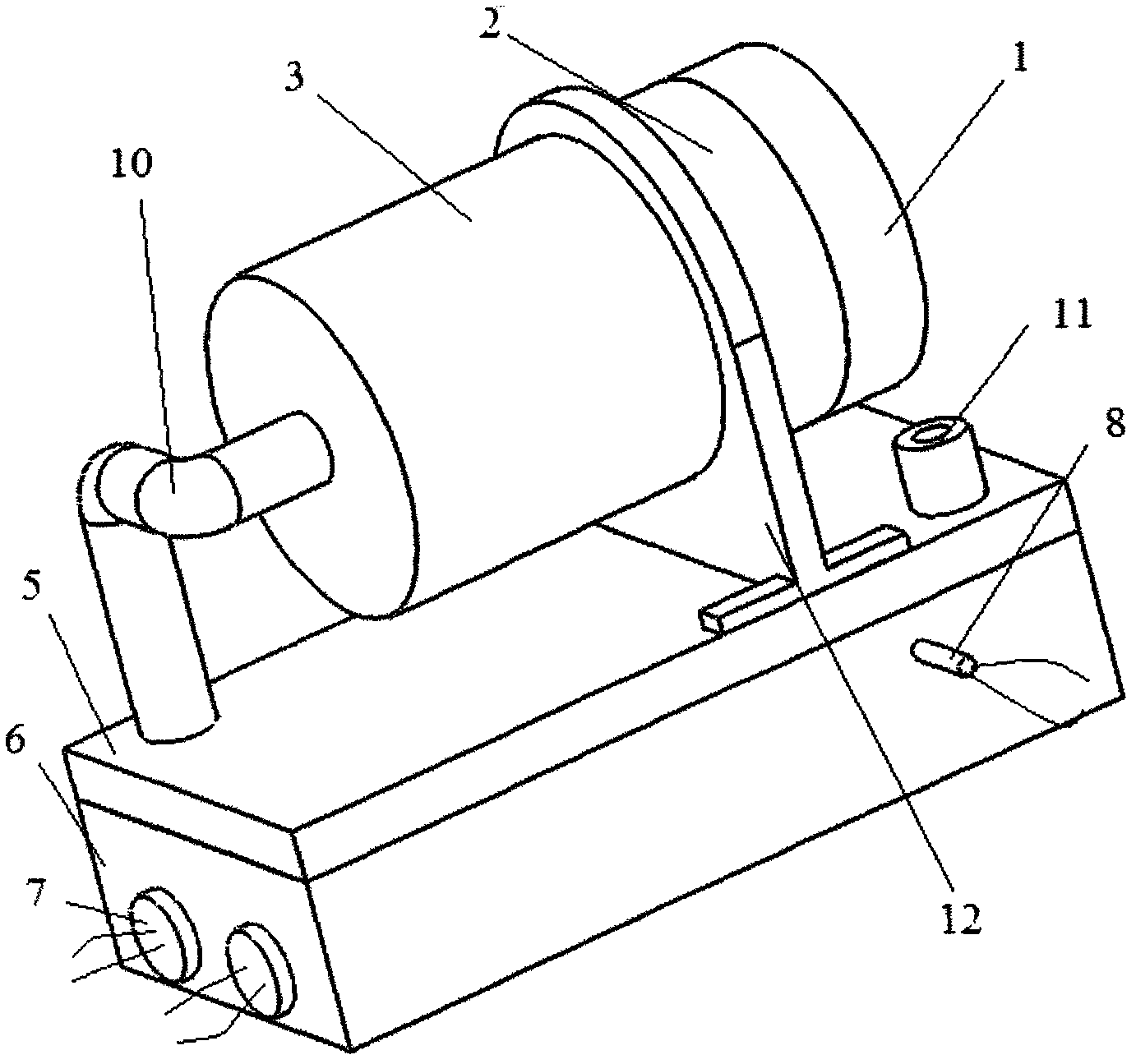

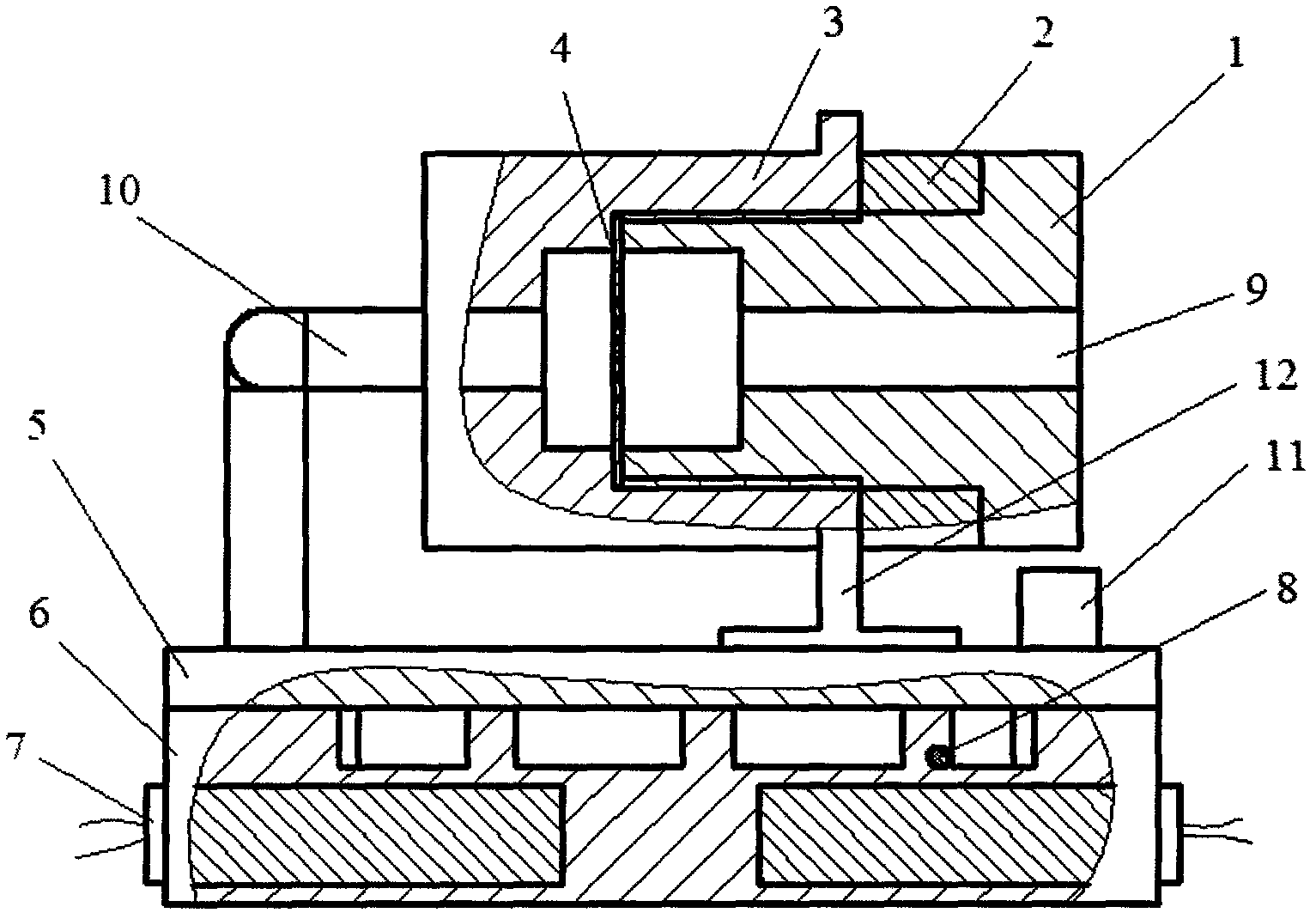

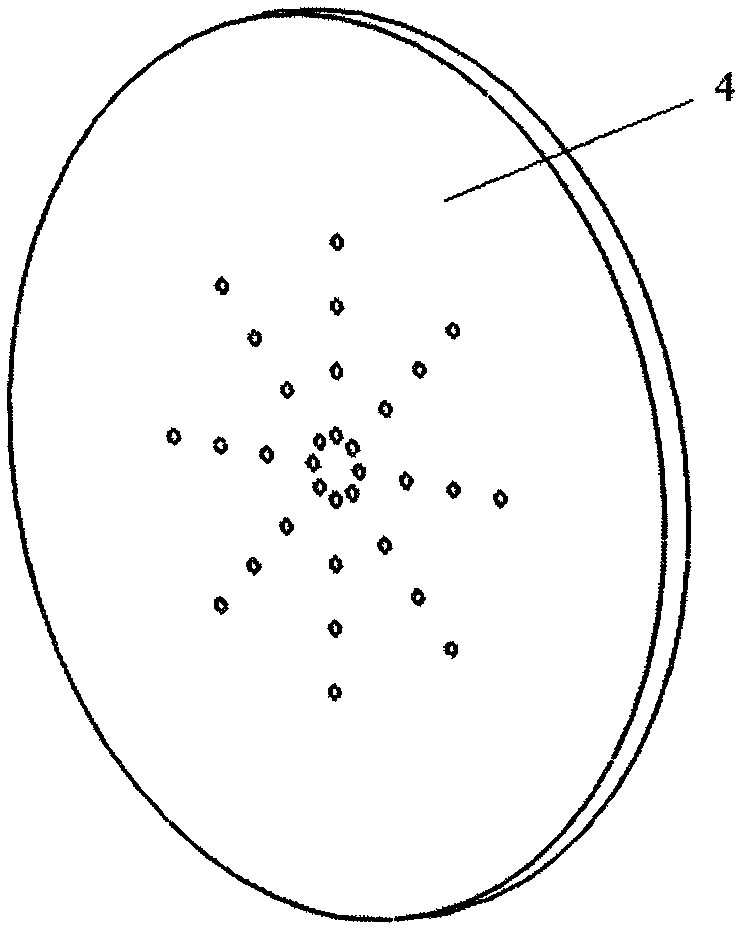

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the present invention includes an evaporation component and an ultrasonic atomization component; the ultrasonic atomization component is installed on the cover plate of the evaporation component through a fixing frame; wherein:

[0026] 1) Evaporation components: including cavity 6, cover plate 5, thermocouple 8 and electric heater 7; on the upper end of cavity 6, there are multiple flow channels composed of interlocking grooves, and one end of the flow channel is connected to cover plate 5. The inlet of the evaporation part on the side is connected, the other end of the flow channel is connected with the outlet 11 of the evaporation part on the other side of the cover plate 5, and the lower end of the flow channel is provided with four electric heaters 7, two of which are arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap