Dresser

A grinding wheel dresser and dresser technology, which is applied in the direction of abrasive surface adjustment devices, grinding machine parts, metal processing equipment, etc., can solve the problems of wasting machine space, poor applicability of rollers, high use cost, etc., and achieve low processing and manufacturing costs , excellent performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

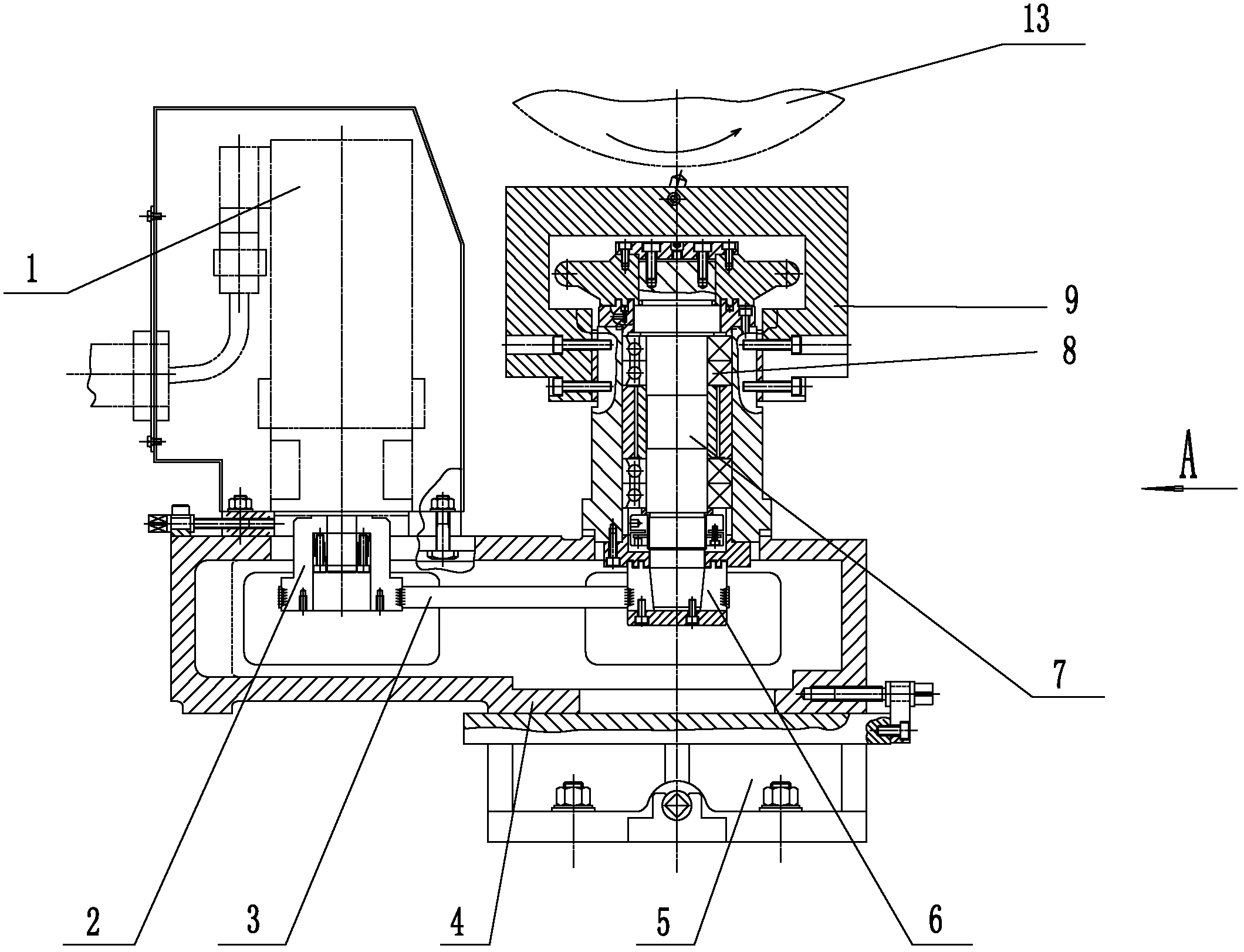

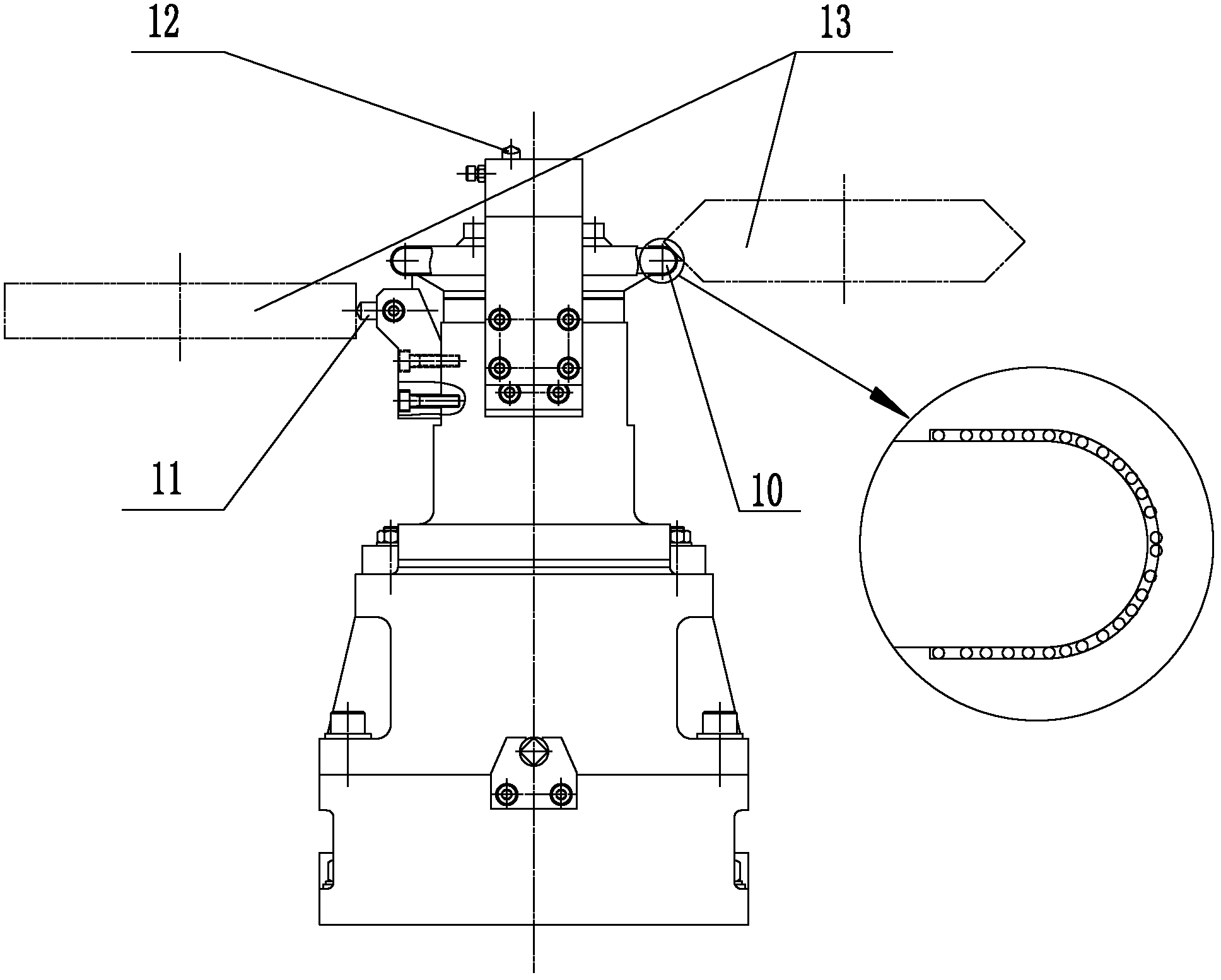

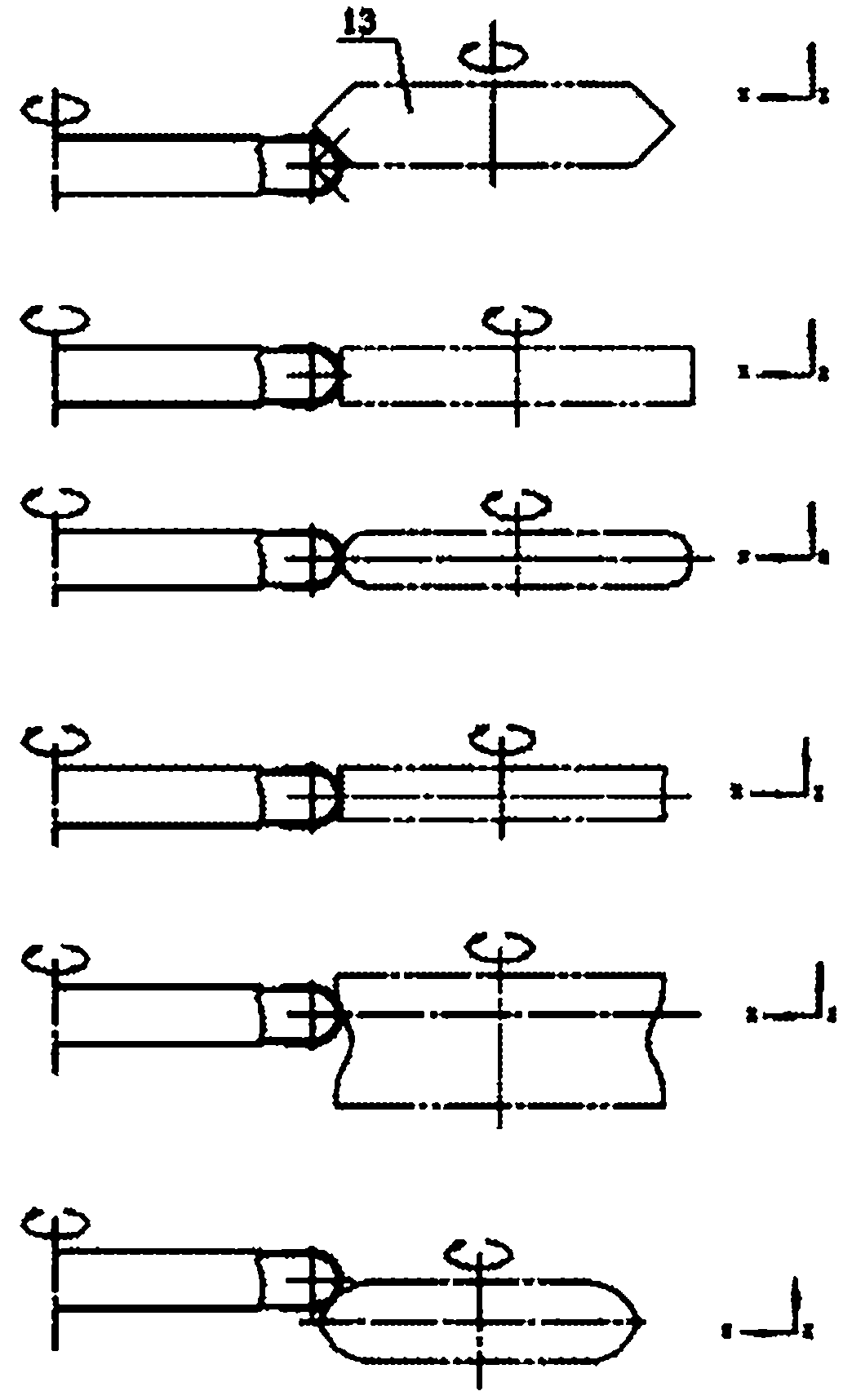

[0015] Such as figure 1 and figure 2 As shown, the drive spindle motor 1 drives the motor pulley 2 with a tensioner to rotate, and the pulley 2 drives the roller spindle 7 to rotate through the belt 3. The spindle 7 is equipped with high-precision group bearings to ensure its accuracy. Arc diamond rollers are mounted on precision spindles for high-speed rotation dressing of grinding wheels. Combination support 9 is installed on the overcoat of roller main shaft, is stationary during the trimming process, and its single-point trimming utilizes the rotation of emery wheel itself so as to contact diamond nib to dress emery wheel. Since the combined support 9 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com