System for simulating molten steel solidification heat-transfer process inside continuous casting crystallizer

A technology of continuous casting crystallizer and simulation system, which is applied in the direction of casting equipment, indicating equipment/measurement equipment configuration, manufacturing tools, etc. It can solve the complex calculation process, large applicability difference of different models, and difficulty in quickly obtaining crystallizers. Internal thermal boundary conditions and other issues, to achieve the effect of high applicability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1. A simulation system for the solidification and heat transfer process of molten steel in a continuous casting mold

[0029] The system consists of three parts: model data initialization module, data operation module and result output module. The model data initialization module is composed of the continuous casting machine database, the physical parameter database and the production process database in turn, and the interface and data operation are set up on the module. The input end of the module is connected; the data running module is composed of a one-dimensional calculation model and a two-dimensional calculation model, which is used to simulate the solidification and heat transfer process of molten steel in the continuous casting mold; the result output module is used to display and save the calculation results. The module is composed of automatic data output saving function and calculation result graphic display function, and an interface is set up on the m...

Example Embodiment

[0033] Example 2: Casting Stb32 steel on a 1000 mm×200 mm slab continuous casting machine.

[0034] Specific steps are as follows:

[0035] 1. Model data initialization process:

[0036] Firstly, confirm the two-dimensional calculation model of the slab, the mold size of 1000 mm×200 mm, the mold height of 900 mm, the position of the meniscus 100 mm, the time step length of 0.1 s, and the space step length of 10 mm; secondly, by confirming the steel type Stb32, Obtain the physical parameters of the steel; finally, in the production process database, it is confirmed that the casting temperature is 1572°C, the pulling speed is 1.2 m / min, the effective thickness of the mold copper plate is 24 mm, the initial temperature of the mold cooling water is 35°C, and the flow rate is 8 m / s.

[0037] 2. Data simulation calculation process:

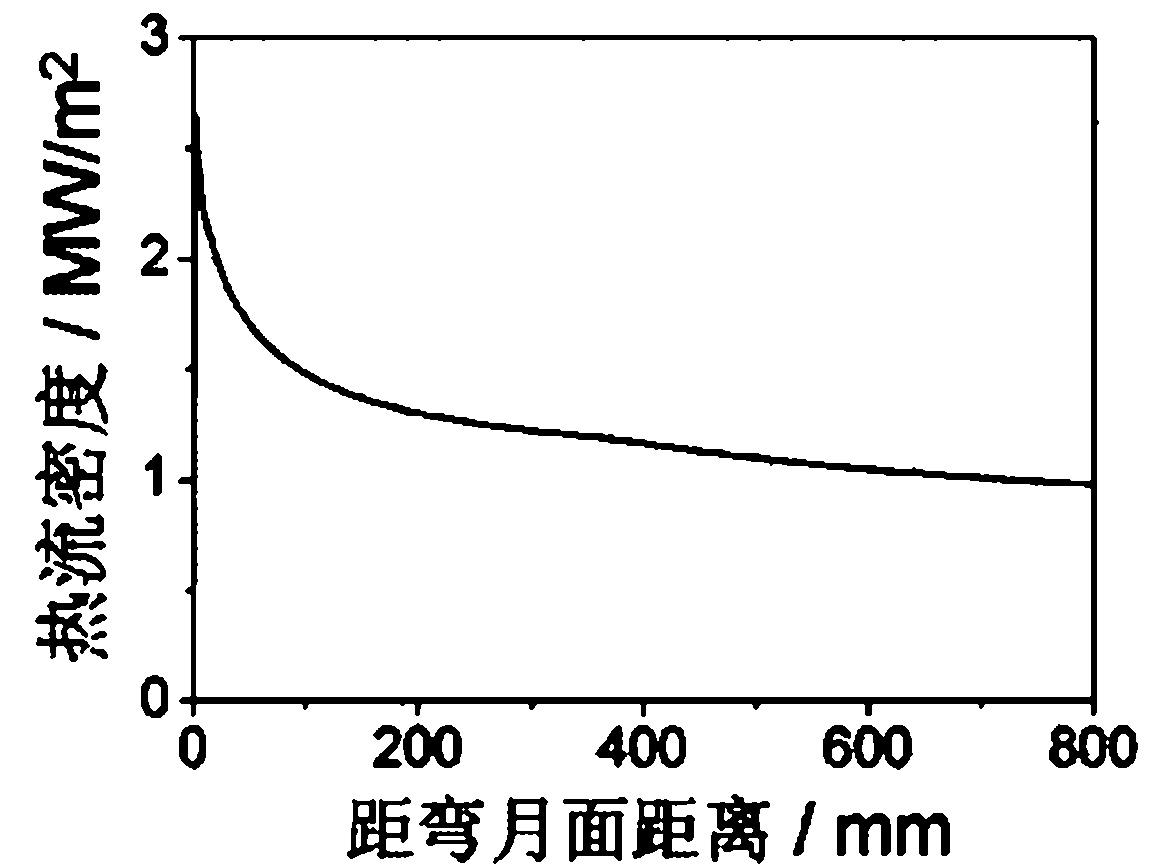

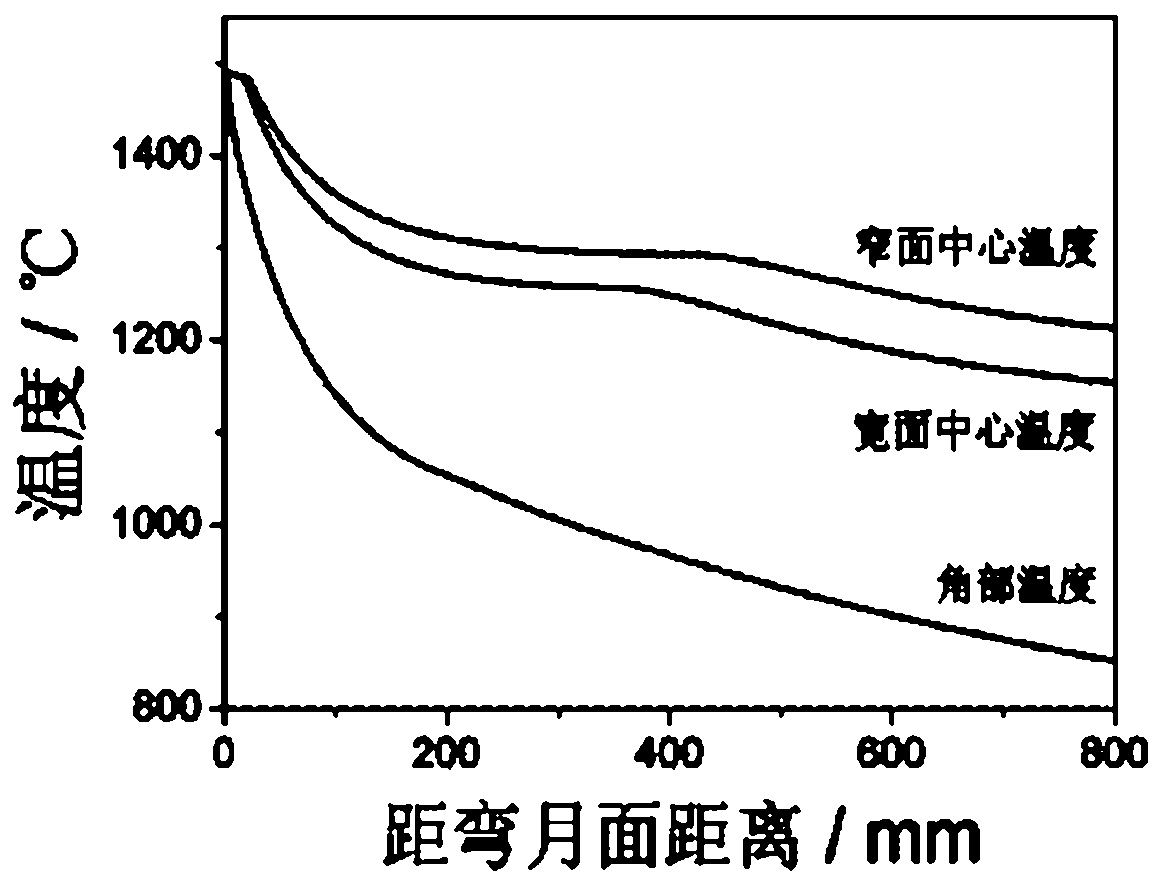

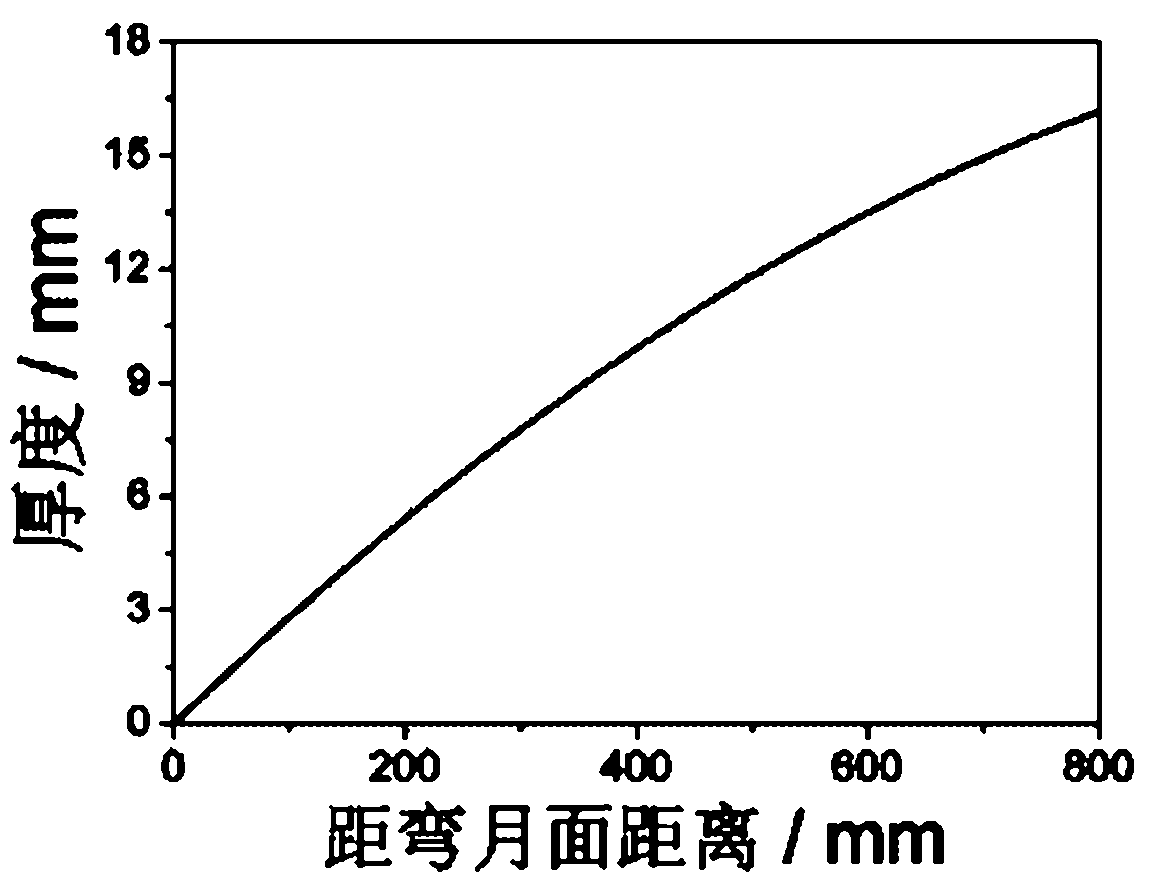

[0038] By receiving the initial data from the model data initialization process, the two-dimensional calculation model formulas (1) and (2) are used in the sim...

Example Embodiment

[0047] Example 3: Casting Q235 steel on a 150 mm×150 mm billet continuous casting machine.

[0048] Specific steps are as follows:

[0049] 1. Model data initialization process:

[0050] First, confirm the two-dimensional calculation model of the slab, the size of the mold 150 mm×150 mm, the height of the mold 1000 mm, the position of the meniscus 100 mm, the time step length of 0.1 s, and the space step length of 10 mm; secondly, by confirming the steel type Q235, Obtain the physical properties of the steel; finally, in the production process database, confirm that the casting temperature is 1535℃, the pulling speed is 3m / min, the effective thickness of the mold copper plate is 14 mm, the initial temperature of the mold cooling water is 35℃, and the flow rate is 8 m / s.

[0051] 2. Data simulation calculation process:

[0052] By receiving the initial data obtained from the model data initialization process, the two-dimensional calculation model formulas (1) and (2) are used in the sim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap