Powdered ink separating and recycling device for detecting

A technology for separation, recycling and toner, applied in the fields of electrography, optics, instruments, etc., can solve the problems of non-compliance with energy saving and consumption reduction, waste, human harm, etc., to improve the input-output rate, reduce testing costs, and reduce carbon emissions. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

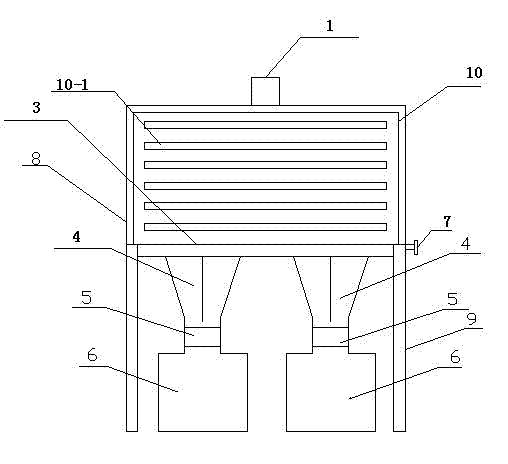

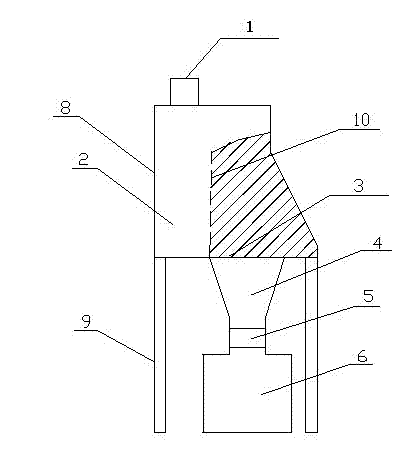

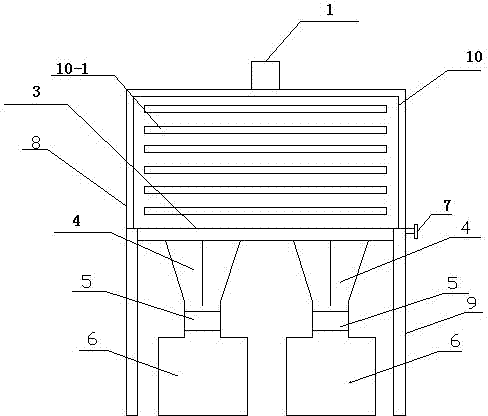

[0008] like figure 1 , figure 2 As shown, the toner separation and recovery device includes negative pressure suction port 1, dust absorption channel 2, detection operation table 3, toner recovery funnel 4, connection sleeve 5, toner recovery tank 6, grounding contact 7, and metal machine cover 8. The frame 9, the baffle plate 10, and the metal machine cover 8 are welded (also can be other connection methods) on the frame 9, and the table top of the frame 9 is the detection operation table 3; The opening is the negative pressure suction port 1, and the negative pressure suction port 1 is connected with the air compressor; the rectangular baffle plate 10 with six rectangular through holes 10-1 is fixed on the four-panel surface in the metal machine cover 8, and the baffle plate The cavity formed between 10 and the rear panel of the machine cover 8 is the dust absorption channel 2; two holes are opened on the detection operation table 3, and the upper ports of the two toner re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com