Method for preparing color toner

A color toner and toner technology, applied in the field of color toner preparation, can solve the problems of single resin type, low production efficiency, strict condition control requirements, etc., and achieve the effect of simple method and excellent comprehensive properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

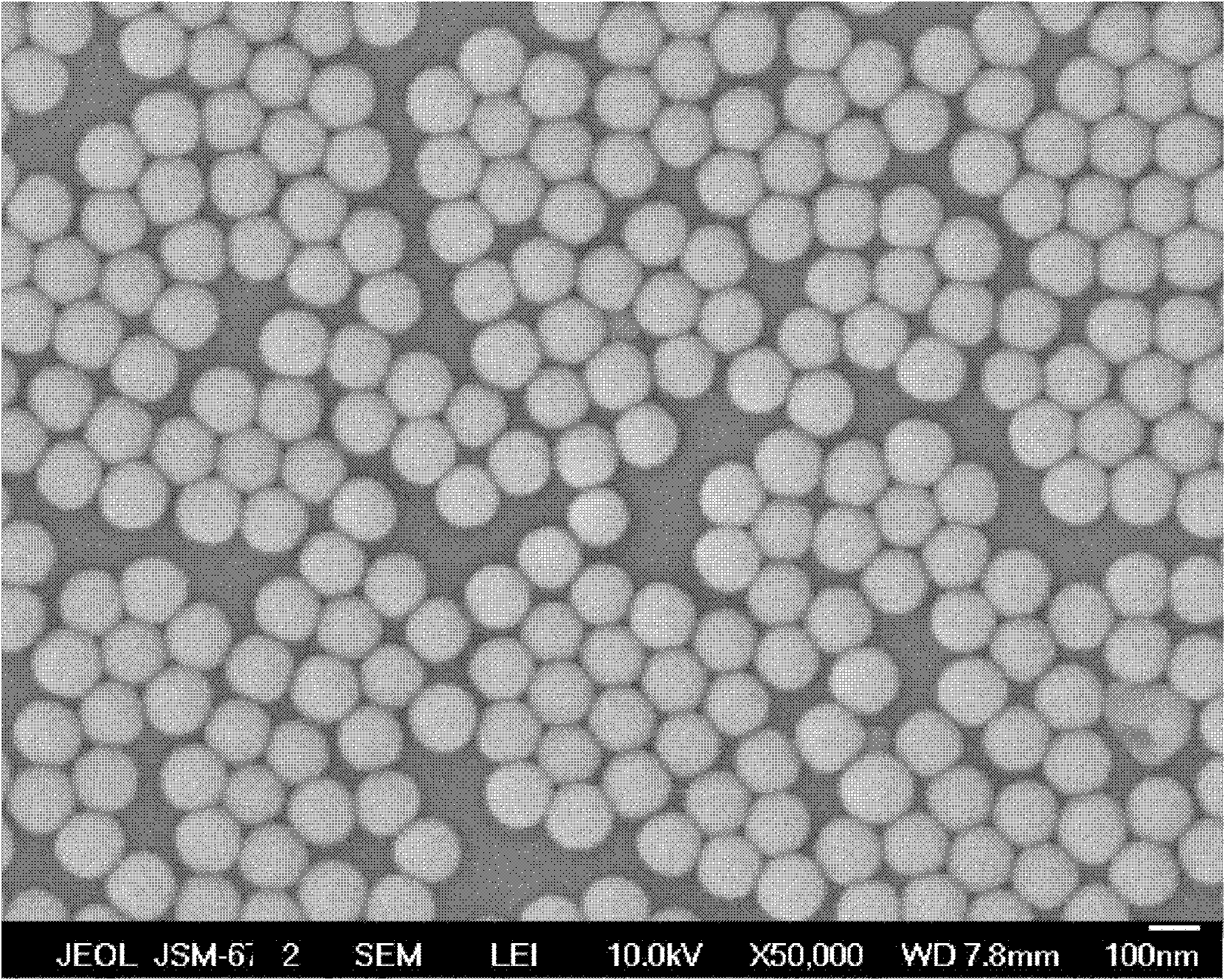

[0024] Nano-resin ball emulsion preparation method A: 20 grams of polystyrene with a Tg of 58° C. and a softening point of 110-120° C. was dissolved in 20 ml of chloroform for later use. Add 200 milliliters of deionized water, 2 grams of sodium dodecylbenzenesulfonate ( DDBS), 1 gram of polyethylene glycol (PEG-4000), 0.5 gram of Span-80 and 0.5 gram of Tween-80, and stir well. Adjust the stirring speed to 5000 rpm, add the polystyrene chloroform solution within half an hour, and stir at 80° C. for 1 hour. Change the condenser tube to distillation mode to remove chloroform, and use vacuum distillation operation to speed up the speed. After the chloroform is determined to be removed, keep the high-speed stirring to cool the temperature to room temperature quickly, and obtain an emulsion of about 100nm polystyrene balls.

[0025] Nano-resin ball emulsion preparation method B: In addition to nano-resin ball emulsion preparation method 1, replace DDBS with anionic surfactant Marl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com