Capacitive touch panel

A capacitive touch and panel technology, which is used in electrical digital data processing, instruments, and data processing input/output processes, etc., and can solve problems such as limited application scope and poor manufacturing yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

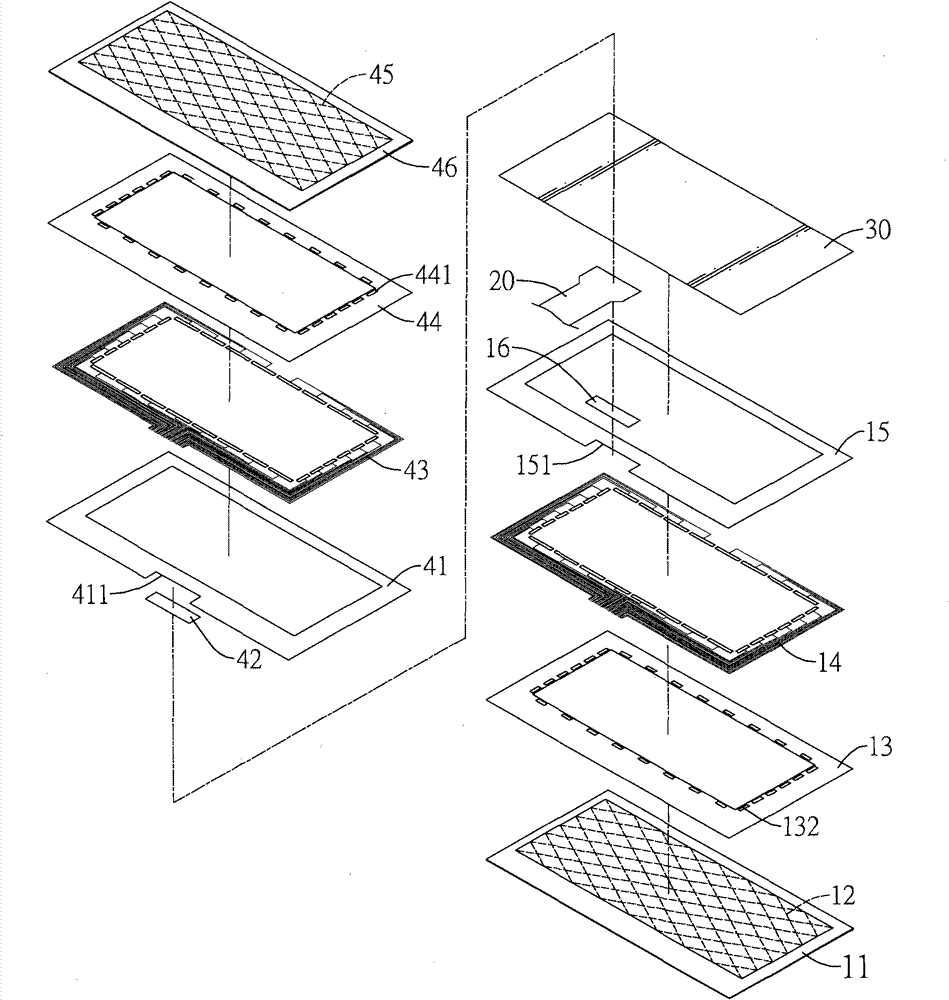

[0026] For a preferred embodiment of the present invention, please refer to figure 1 and figure 2 As shown, it includes a glass substrate 11, a touch sensing circuit layer 12, an insulating ink layer 13, a wire layer 14, an insulating layer 15, a conductive adhesive layer 16, a flexible circuit board 20, and a transparent insulating layer. Adhesive layer 30, an upper insulating layer 41, an upper conductive adhesive layer 42, an upper wire layer 43, an upper insulating ink layer 44, an upper touch sensing circuit layer 45, a glass cover 46, an upper protective layer 51 And the protective layer 52 below.

[0027] The glass substrate 11 has a circuit surface 111 .

[0028] The above-mentioned lower touch sensing circuit layer 12 is formed on the circuit surface 111 of the glass substrate 11; Circuit composition, such as X-axis touch circuit.

[0029] The lower insulating ink layer 13 is formed and covered on the edge of the lower touch sensing circuit layer 12, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com