A scallop shelling method based on high static pressure technology

A high static pressure, scallop technology, applied in the field of food processing, can solve the problems of shellfish meat quality and freshness damage, low degree of mechanization, low production efficiency, etc., to increase the processing capacity of shelling and reduce processing energy consumption , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

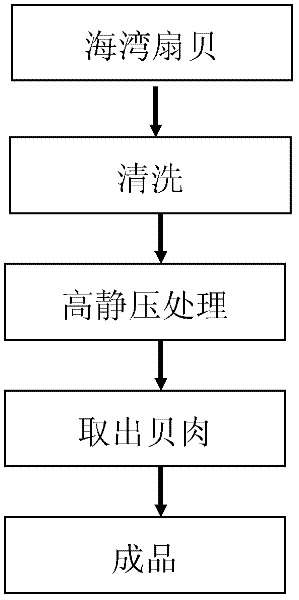

Image

Examples

Embodiment 1

[0012] Embodiment 1, bay scallop is shelled

[0013] Wash the fresh bay scallops with clean water and put them into a high static pressure container (volume 30L), seal them, pressurize to 200MPa and keep the pressure for 3 minutes, open the high static pressure equipment, take out the scallops, the scallop meat and shell will automatically Separation allows the scallop meat to be removed directly from the double shell. The treatment process under the conditions of pressure and pressure holding time was evaluated for process effect, and the obtained research data were compared with the shelling knife shelling without high static pressure treatment. It was found that the shelling time of this treatment process can be shortened to 1 / 30, reducing the It improves the difficulty of shelling, improves the integrity of scallop meat, the complete shelling rate can reach 100%, and the meat production rate increases by about 17% (the manual method meat production rate is 55%-58%), which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com