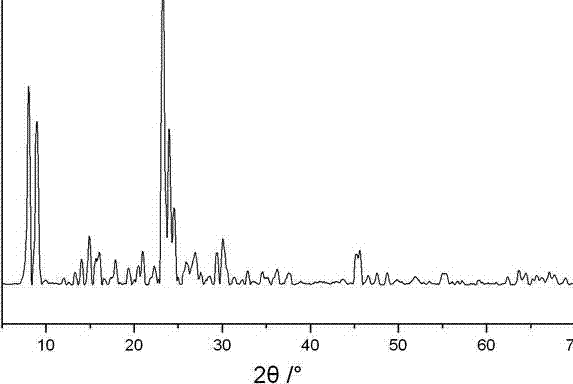

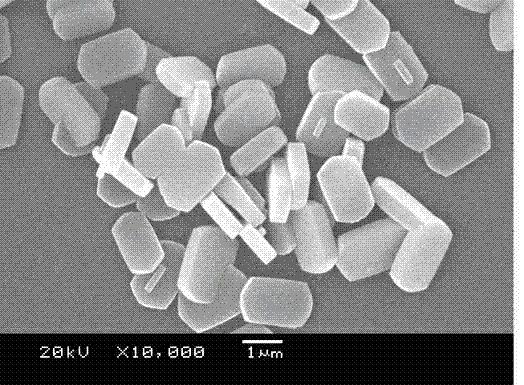

ZSM-5 molecular sieve for synthesizing propylene from methanol, preparation method and application thereof

A ZSM-5, methanol synthesis technology, applied in molecular sieve catalysts, chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problems of low P/E ratio, low propylene selectivity, etc., and reduce the preparation cost. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0055] Example 1

[0056] The raw material components of the molecular sieve in this embodiment are:

[0057] 144g of silica sol, the SiO of the silica sol 2 The mass percentage is 24%, Na 2 The mass percentage of O is 0.042%, and the mass is SiO 2 8.5 times the mass of deionized water, the mass is SiO 2 The mass of 50% tetrapropyl ammonium bromide, the aluminum source is aluminum sulfate, and Al 2 O 3 Calculated, the quality of aluminum sulfate is SiO 2 1.33% by mass, sodium hydroxide solution, concentrated sulfuric acid solution.

[0058] The molecular sieve is prepared from the above-mentioned component raw materials by the following method:

[0059] First, weigh 144g of silica sol, add the deionized water to dilute, add sodium hydroxide solution at a rate of 1ml / min to adjust the pH to 13, and stir well, then add tetrapropylammonium bromide dropwise at a rate of 1ml / min To this solution, then add aluminum sulfate dropwise, and finally add sulfuric acid solution to adjust the pH t...

Example Embodiment

[0063] Example 2

[0064] The raw material components of the molecular sieve in this embodiment are:

[0065] 144g of silica sol, the SiO of the silica sol 2 The mass percentage is 26%, Na 2 The mass percentage of O is 0.0485%, and the mass is SiO 2 7 times the mass of deionized water, the mass is SiO 2 The mass of 50% tetrapropyl ammonium bromide, the aluminum source is aluminum sulfate, and Al 2 O 3 Calculated, the quality of aluminum sulfate is SiO 2 0.57% by mass, potassium hydroxide solution, concentrated hydrochloric acid solution.

[0066] The molecular sieve is prepared from the above-mentioned component raw materials by the following method:

[0067] First, weigh 144g of silica sol, add deionized water to dilute, add potassium hydroxide solution at a rate of 2ml / min to adjust the pH to 13, stir well, then add tetrapropylammonium bromide dropwise at a rate of 2ml / min to The solution, then aluminum sulfate was added dropwise, and finally concentrated hydrochloric acid solution...

Example Embodiment

[0071] Example 3

[0072] The raw material components of the molecular sieve in this embodiment are:

[0073] 144g of silica sol, the SiO of the silica sol 2 The mass percentage is 25%, Na 2 The mass percentage of O is 0.046%, and the mass is SiO 2 8.5 times the mass of deionized water, the mass is SiO 2 30% by mass of tetrapropylammonium bromide, aluminum source is aluminum chloride, and Al 2 O 3 Calculated, the quality of aluminum chloride is SiO 2 0.28% by mass, sodium carbonate solution, concentrated nitric acid solution.

[0074] The molecular sieve is prepared from the above-mentioned component raw materials by the following method:

[0075] First, weigh 144g of silica sol, add deionized water to dilute, add sodium carbonate solution at a rate of 1.5ml / min to adjust the pH to 13, and stir well, add tetrapropylammonium bromide at a rate of 1.5ml / min to The solution is then added dropwise to the aluminum source, and finally concentrated nitric acid solution is added to adjust the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap