Method and system for pretreatment of cold-rolled leveling liquor wastewater

A technology of leveling liquid and pretreatment, which is applied in water/sewage multi-stage treatment, flotation water/sewage treatment, neutralized water/sewage treatment, etc. It can solve the problem of high effluent COD concentration, uncontrollable effluent quality, and one-time investment. Advanced problems, to achieve the effect of low one-time investment, stable treatment effect, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] The present invention will be described in detail below with reference to the drawings and embodiments.

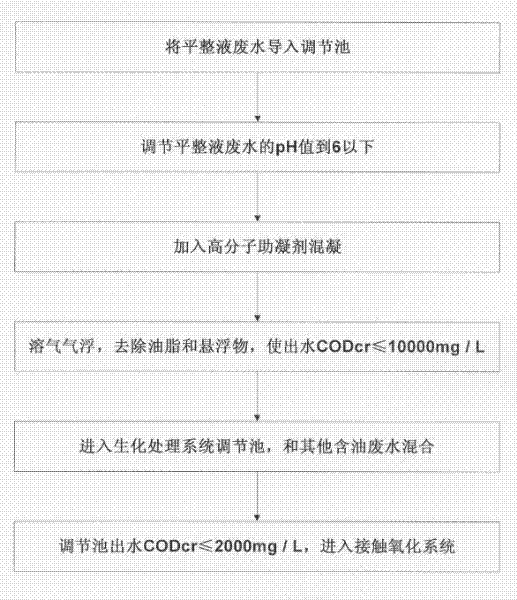

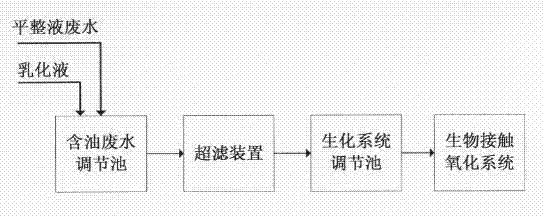

[0036] See figure 1 , The present invention provides a method for pretreatment of cold-rolling leveling liquid wastewater, including the following steps:

[0037] (1) Lead the leveling liquid wastewater into the regulating tank.

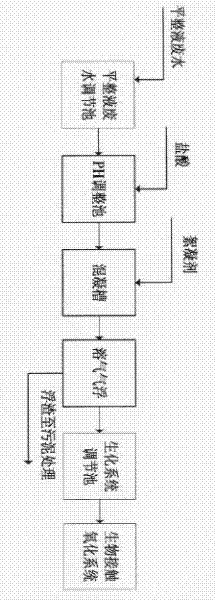

[0038] (2) Adjust the pH value of the leveling liquid wastewater to below 6.

[0039] (3) Add polymer coagulant aid for coagulation. Choose 1‰ of PAM as coagulant, and the dosage is 5mg / L.

[0040] (4) Dissolved air flotation, remove grease and suspended matter, make the effluent CODcr≤10000mg / L. The gas-water ratio is controlled to be 0.04:1~0.08:1, the waste water return ratio is 25%~40%, and the residence time is 0.5~0.6 hours.

[0041] (5) Enter the regulating tank of the biochemical treatment system and mix with other oily wastewater.

[0042] (6) The effluent CODcr of the regulating tank is less than or equal to 2000mg / L and enters the contac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap