A static pressure uniform blowing wind box

A wind box, uniform technology, applied in the direction of dryers, lighting and heating equipment, drying, etc., can solve the problems of uneven air volume, defective products, unfavorable hot air diffusion and uniformity, etc., and achieve the effect that is beneficial to quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

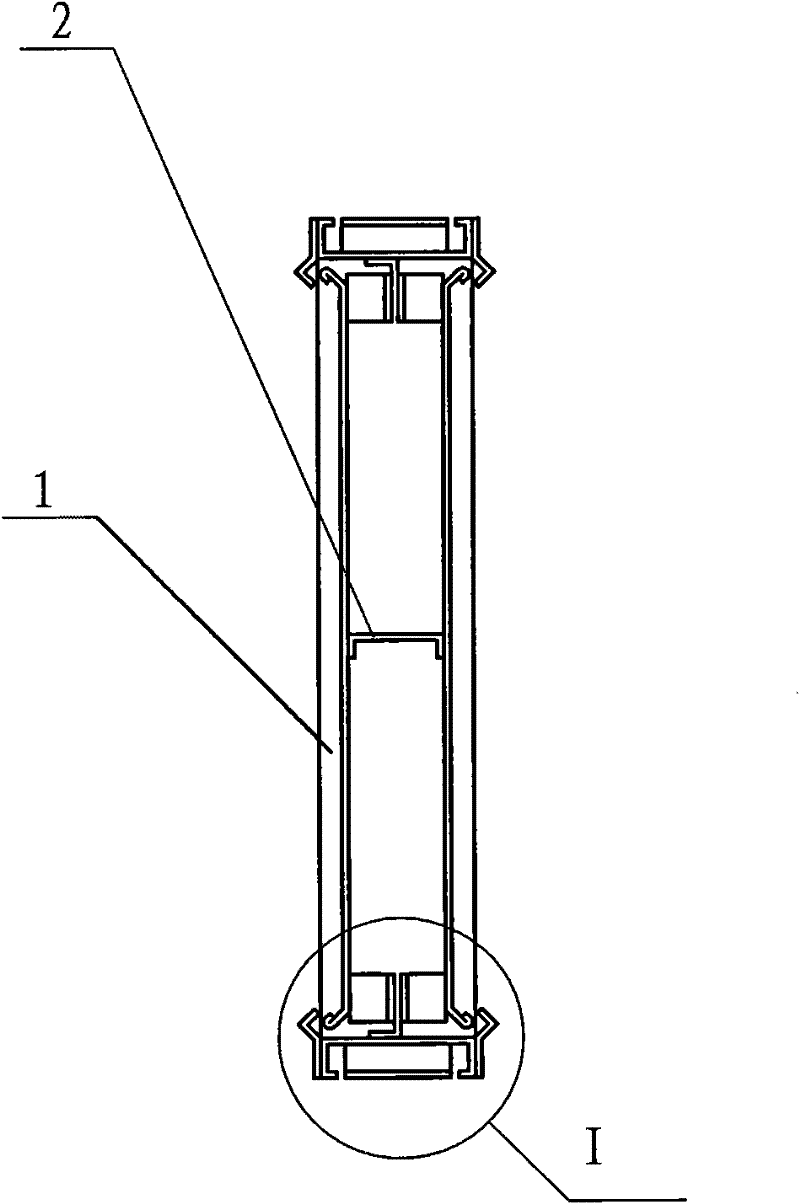

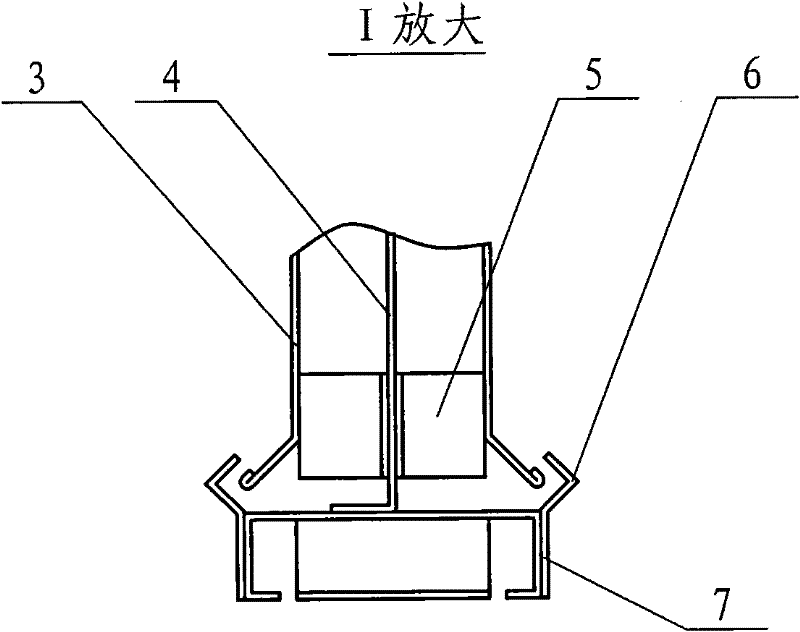

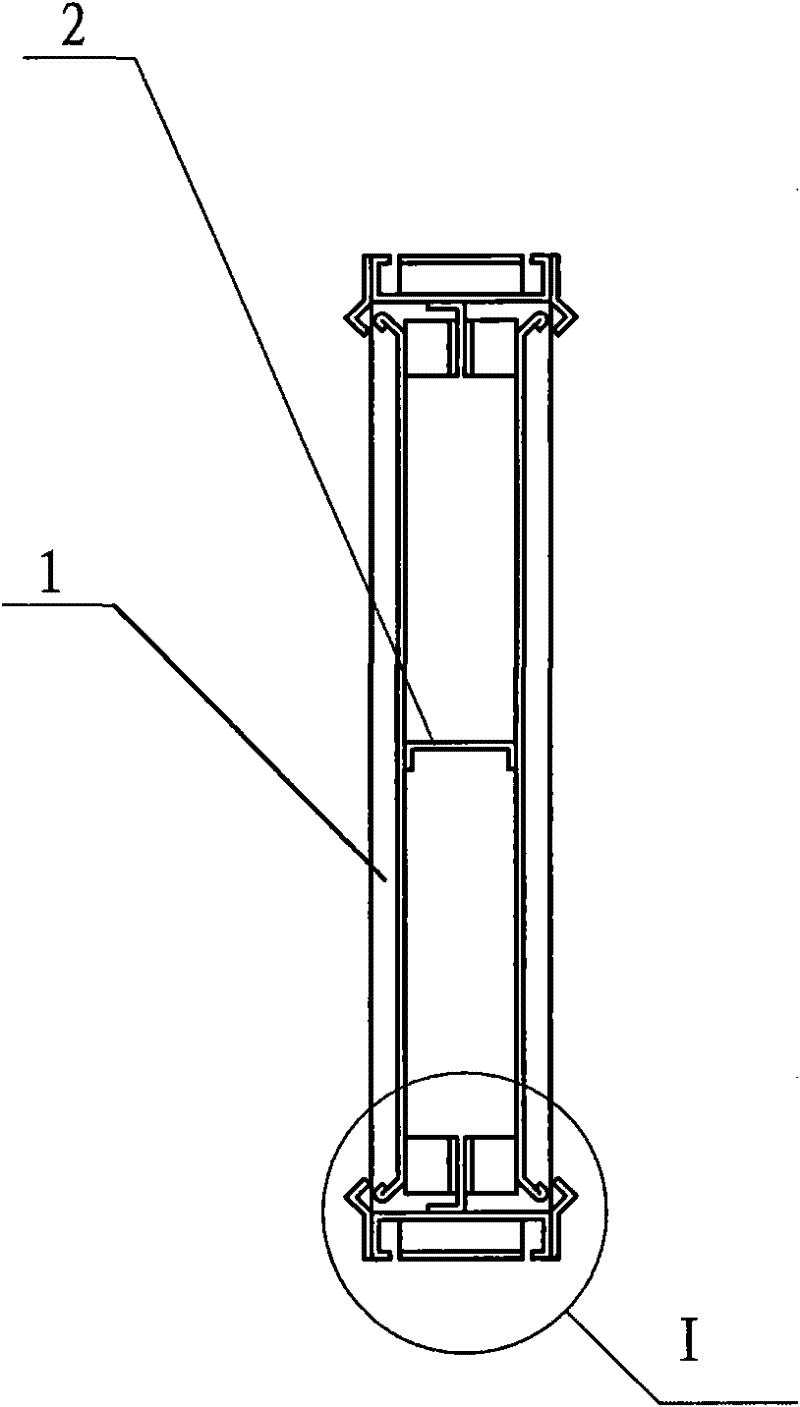

[0012] An embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0013] The present invention comprises a windshield small angle iron 1, a dividing plate 2, a wind box panel 3, a spacer grid plate 4, a wind deflector 5, a windshield guide plate 6, and a wind box side plate 7. First mold each part, combine the air deflector 5 with the spacer grid plate by spot welding, and then combine with the side plate 7, combine the air box panel 3, the partition plate 2, and the small angle iron for wind protection in the master form, shape and complete Straight, the formed windshield guide plate 7 is riveted on the wind box with a blind rivet, and spot welding treatment is performed on the spot where it is not firmly attached, so that the windshield guide plate 7 is firmly attached to the wind box, and the finished product is sanded and smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com