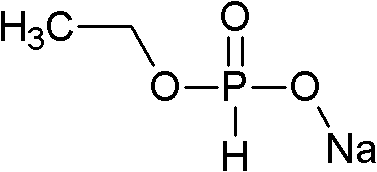

Production method of sodium 0-ethylphosphate

A technology of sodium ethyl phosphate and a production method, which is applied in the direction of phosphorus organic compounds, can solve the problems of excessive impurity phosphite and chloride, difficulty in meeting the demand of the international market, and insufficient stability of the content, and achieve the effect of stable content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The production method of 0-ethyl sodium phosphate is characterized in that phosphorus trichloride and ethanol rapidly complete the chemical reaction under the condition of negative pressure and 15 degrees Celsius, and at the same time, under the temperature condition of 70-85 degrees Celsius, the deacidification pot is used in high vacuum The hydrogen chloride and ethyl chloride gas produced in the reaction process are quickly removed, so that the diethyl phosphite content of the reactant reaches more than 80%, and the acidity is less than 5%.

[0020] After the diethyl phosphite is cooled to a temperature of 10 degrees Celsius, a sodium hydroxide solution of a certain concentration is added dropwise in the temperature range of 60-70 degrees Celsius, and then the temperature is gradually raised to 70 degrees Celsius and kept for two hours. After the reaction is finished, the measured pH value is 7.5, which is the end point of the reaction. Otherwise, sodium hydroxide or ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap