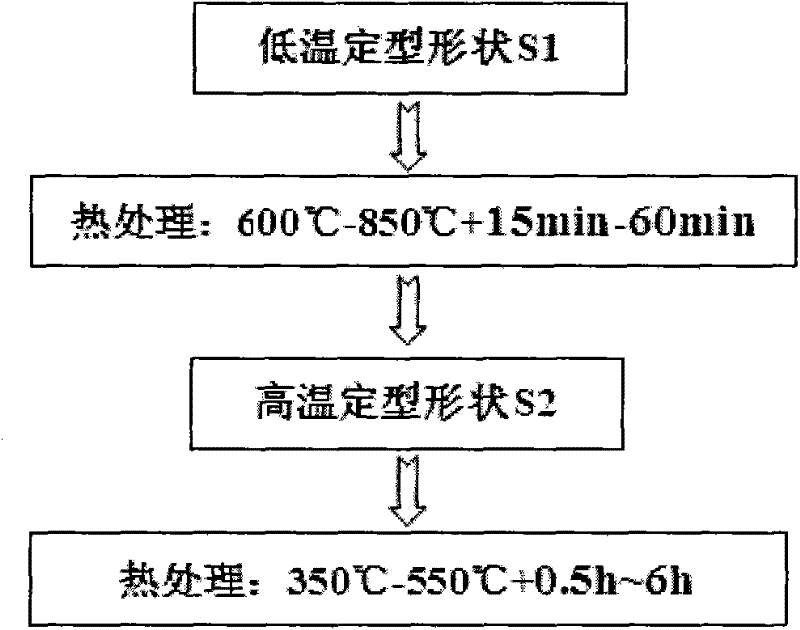

A method for fabricating two-way memory devices using double-constraint annealing

A device, two-way technology, applied in the field of two-way memory device manufacturing by annealing nickel-titanium-based alloys with solid solution and aging double constraints, can solve the problem of sensitivity to training temperature, setting temperature and training times, poor pre-design of double memory stroke, Two-way memory performance and stability are poor, achieving the effects of strong industrial practicability, low cost, and large strain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

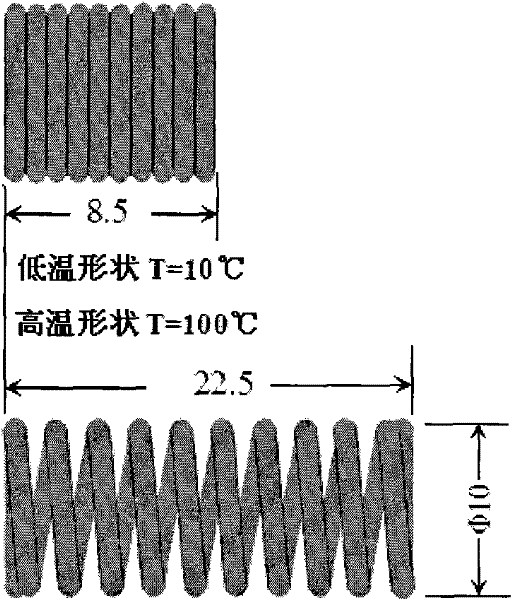

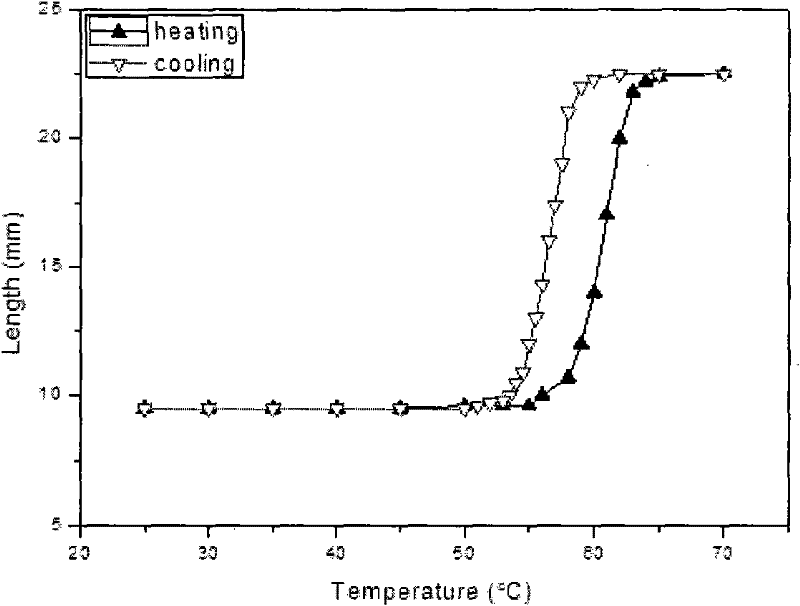

[0025] A binary nickel-titanium memory alloy whose composition is Ni: 56wt.%, Ti: 44wt.% is selected, and the raw material is a wire with a diameter of Φ0.8mm. Wind the wire on a Φ8mm helical spring mold according to the pre-strain, the pre-strain is ε=10%, the spring parameters are: pitch d=0mm, number of turns n=10, spring length L1=8.5mm, the wire The shape of the material is fixed, placed in a constant temperature furnace at 650°C for 0.5h, and then water-cooled. The obtained spring was stretched and constrained again to a length of L2=22.5 mm, then fixed, placed in a constant temperature furnace at 500° C. for 2 hours, and cooled in air. Take out the prepared spring device, the schematic diagram of the action of the two-way memory spring is as follows figure 2 As shown, the two-way stroke is: the spring stretches when the temperature rises, and the spring contracts when the temperature cools down.

[0026] Place the spring in a displacement-temperature tester to measur...

Embodiment 2

[0029] A ternary nickel-titanium memory alloy whose composition is Ni: 55.7wt.%, Ti: 44wt.%, Cr: 0.3wt.%, is selected, and the raw material is a wire with a diameter of Φ1.0mm. The wire is wound on a Φ12mm helical spring mold according to the pre-strain, the pre-strain is ε=8.3%, and the spring parameters are: pitch d=2.0mm, number of turns n=6, spring length L 1 = 20mm, fix the shape of the wire, put it in a constant temperature furnace at 700°C for 45min, and then cool it in water. Constrain the obtained spring again to compression to L 2 = 10mm in length, fixed, put into a constant temperature furnace at 450°C for 1 hour, and air-cooled. Take out the prepared spring device, the schematic diagram of the action of the two-way memory spring is as follows figure 2 As shown, the two-way stroke is: the spring contracts when the temperature rises, and the spring elongates when the temperature cools down.

[0030] After testing, the starting temperature of spring heating is 3°C...

Embodiment 3

[0032] A ternary nickel-titanium memory alloy whose composition is Ni: 55.4wt.%, Ti: 44wt.%, V: 0.6wt.% is selected, and the raw material is a wire with a diameter of 1mm. Wind the wire on the flat mold of the special-shaped tower spring according to the pre-strain, the pre-strain range is ε=5-20%, fix the special-shaped tower spring, put it in a constant temperature furnace at 720°C for 0.5h, air cooled. The obtained special-shaped tower spring is vertically stretched and fixed on the mold again, with a height of 35mm, and then placed in a constant temperature furnace at 500°C for 2 hours and cooled in the furnace. The spring phase transition temperature Af=43°C was measured by bending test. Put the special-shaped tower-shaped spring device into hot water above 60°C, and the measured spring height is 35mm, and then put the spring into -10°C alcohol, and the measured spring height is 3mm. After 1000 cycles of cold and heat cycles, the high-temperature shape memory stability ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com