Coiling method for controlling folding defects in flat strip coiling

A strip steel and flattening technology, which is applied in the coiling of strip steel and the coiling field to control the folding defects of flat strip steel coiling, and can solve the problems of product drop group, aggravated folding defects, large coiling tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

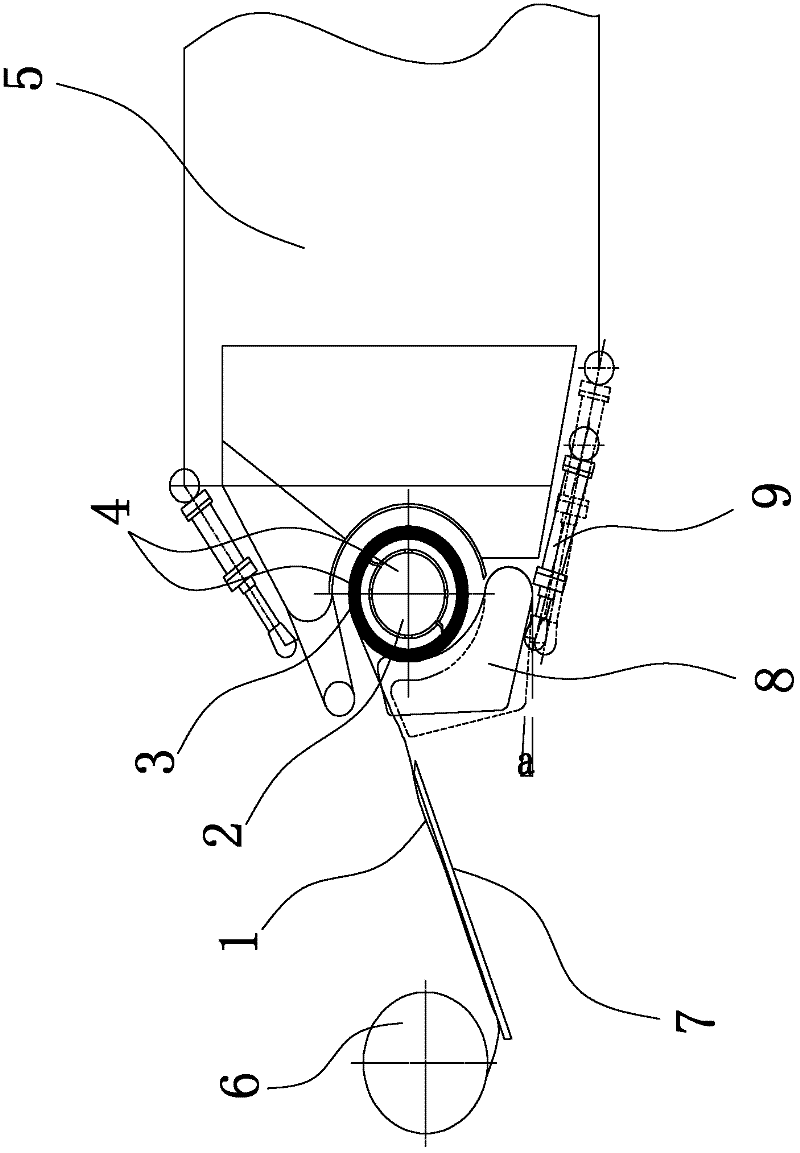

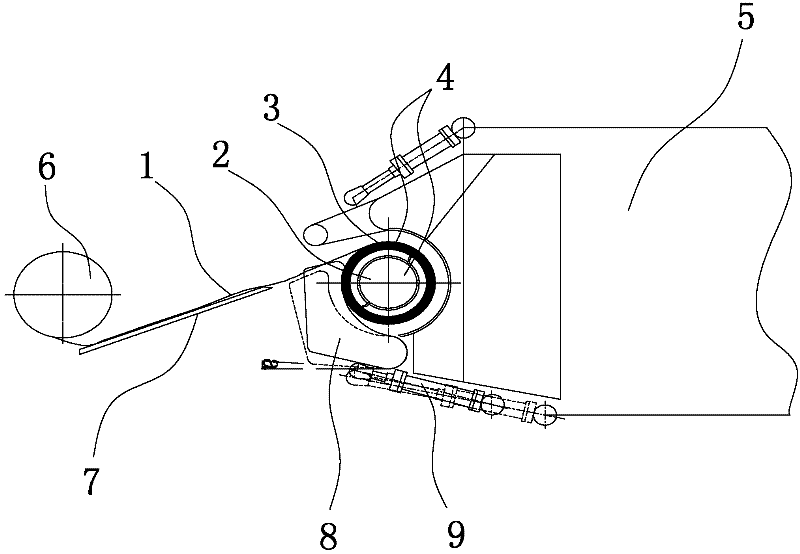

[0014] Such as figure 1 Shown is a coiling method provided by the present invention that can effectively reduce crease defects formed in the coiling process of the flat steel strip and control the crease defects in coiling of the flat steel strip. The coiling method comprises the following steps,

[0015] First, on the outer surface of the reel body 2 of the coiler for coiling strip steel 1, an elastic buffer layer is installed to form a coiler reel 4; On the take-up machine; then start the belt coiler 5, so that the reel 4 of the coiler enters the belt coiler 5, at the same time, start the tension roller group of the leveling unit, and pass the strip steel 1 through the outlet tension roller of the tension roller group 6 and the outlet guide plate 7 are transported to the outer surface of the coiler drum 4, and are coiled to the outer surface of the coiler drum 4 with the assistance of the belt coiler 5; when the strip 1 is on the coiler After the outer surface of the reel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com