A Selective Hydrogenation Process of C4 Stream with High Alkyne Content

A technology for selective hydrogenation and high alkynes, which is applied in the purification/separation of hydrocarbons, hydrogenation to hydrocarbons, hydrocarbons, etc. It can solve the problems of complex process, large investment and high difficulty in operation, so as to inhibit deposition and improve economic benefits. , the effect of reducing the temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

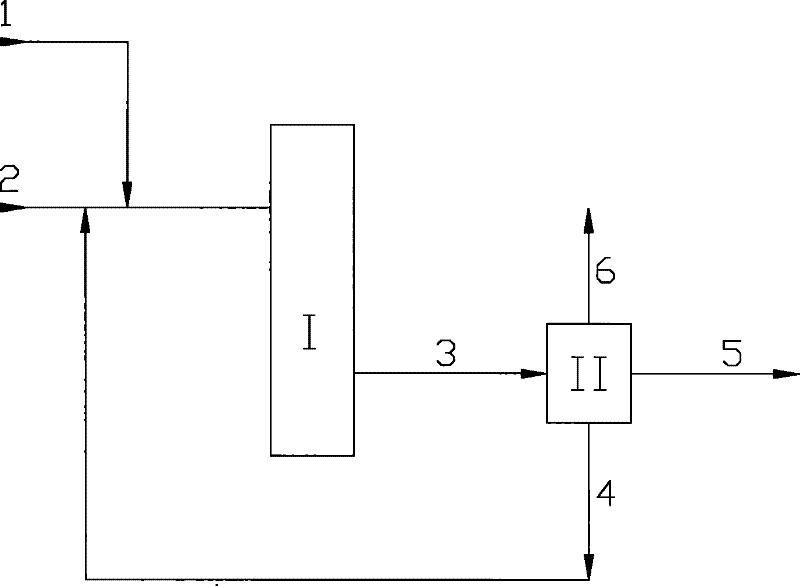

[0024] Example 1

[0025] The raw material used in this example is the high acetylene carbon four discharged from the industrial butadiene extraction unit. The catalyst adopts the multi-metal selective hydrogenation catalyst described in CN00107257.9, the catalyst carrier is Al2O3, and the metal component content is: palladium 0.2wt %, 11.3wt% copper and 0.2wt% silver. A two-stage adiabatic fixed-bed process is adopted, with a reactor with a catalyst loading volume of 50ml and a reactor with a catalyst loading volume of 20ml. The fresh high alkyne C4 and the C4 recycled from the first stage of the reactor are mixed into the first stage of the reactor, the first stage of the reactor outlet part is recycled to the first stage of the reactor inlet, the rest enters the second stage of the reactor, the circulation ratio is 19. The second stage reactor serves as the terminal reactor. The inlet temperature of the first stage reactor is 30℃, the pressure is 1.6MPa, the ratio of hydroge...

Example Embodiment

[0028] Example 2

[0029] The raw material used in this embodiment is high acetylene carbon four discharged from an industrial butadiene extraction device. The catalyst adopts a palladium / lead selective hydrogenation catalyst, the catalyst carrier is Al2O3, and the metal component content is: palladium 0.3wt%, lead 0.2wt %. A two-stage adiabatic fixed-bed process is adopted, with a reactor with a catalyst loading volume of 50ml and a reactor with a catalyst loading volume of 20ml. Fresh high alkyne C4 and C4 recycled from the first stage of the reactor are mixed into the first stage of the reactor, the first stage of the reactor outlet part is recycled to the first stage of the reactor inlet, the rest enters the second stage of the reactor, the circulation ratio is 19. The second stage reactor serves as the terminal reactor. The inlet temperature of the first stage reactor is 29℃, the pressure is 1.0MPa, the ratio of hydrogen to alkyne is 0.75, and the space velocity (LHSV) is ...

Example Embodiment

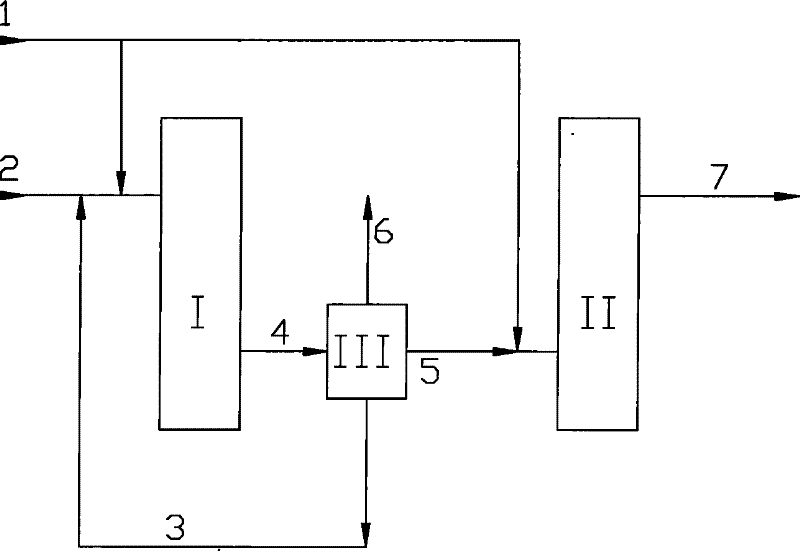

[0036] Example 3

[0037] The raw materials used in this embodiment are high acetylene carbon four discharged from an industrial butadiene extraction device. The catalyst adopts a palladium / lead selective hydrogenation catalyst, the catalyst carrier is Al2O3, and the metal component content is: palladium 0.3wt%, lead 0.2wt %. The three-stage adiabatic fixed-bed process is adopted, the catalyst loading of the first stage reactor is 100ml, the second stage reactor is 100ml, and the third stage reactor is 30ml. Fresh high alkyne C4 and C4 recycled from the second-stage reactor are mixed with a certain amount of hydrogen and then enter the first-stage reactor. After the material at the outlet of the first-stage reactor is cooled, a certain amount of hydrogen is fed into the second-stage reactor. The part C4 at the reactor outlet is recycled to the inlet of the first stage reactor, and the remaining part enters the third stage reactor with a circulation ratio of 11. The three-stage ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap