Internal combustion engine

A technology of internal combustion engine and fuel, which is applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems of fuel injection system cost increase, increase air density, reduce performance impact, prevent exhaust performance and combustion The effect of poor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

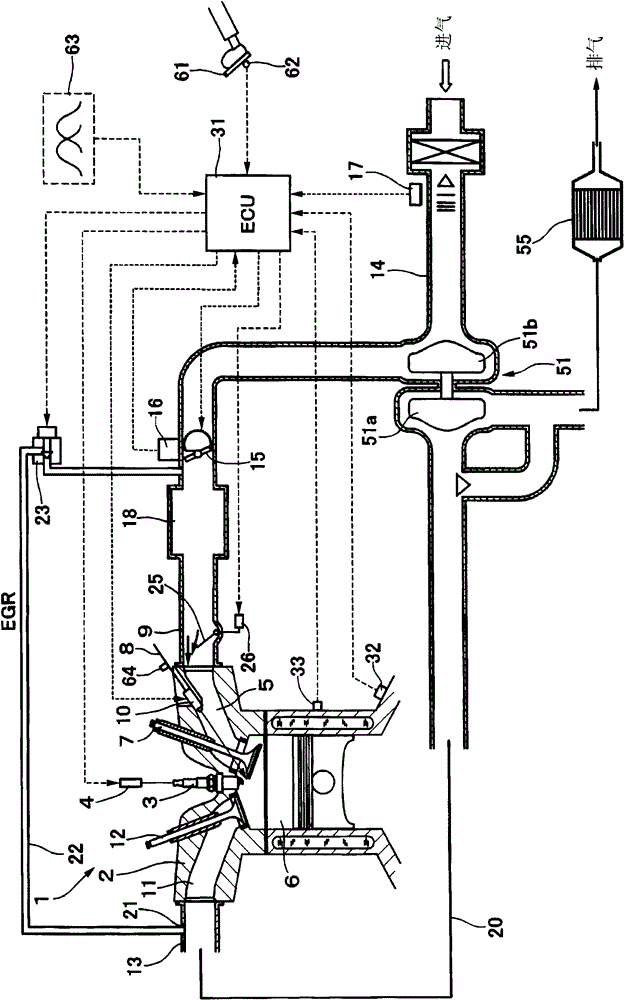

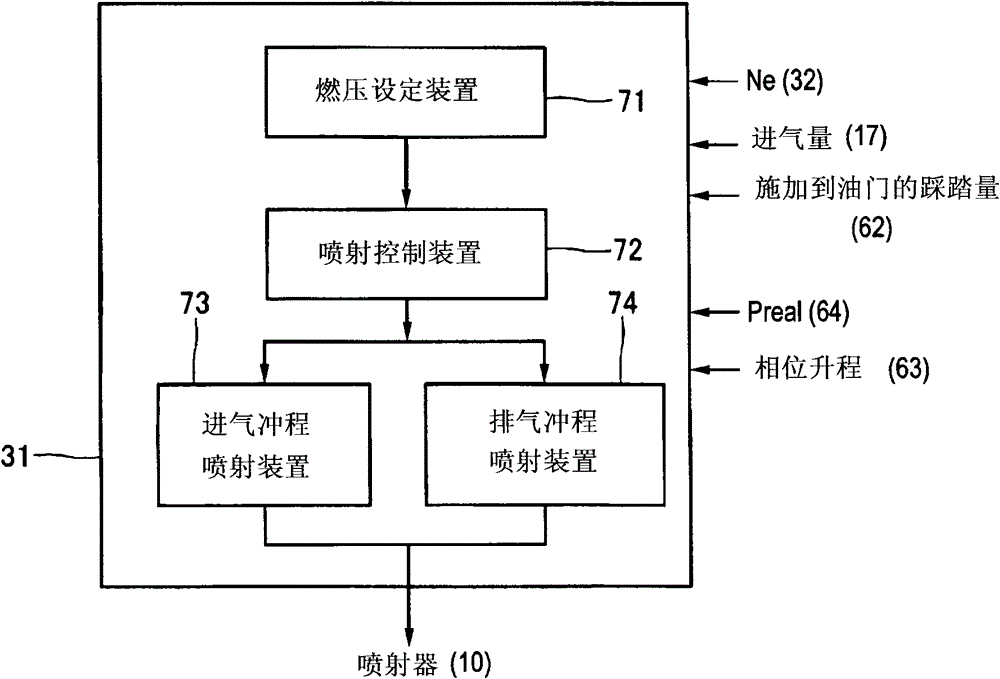

[0038] will refer to figure 1 and figure 2 The internal combustion engine of the present invention will be described.

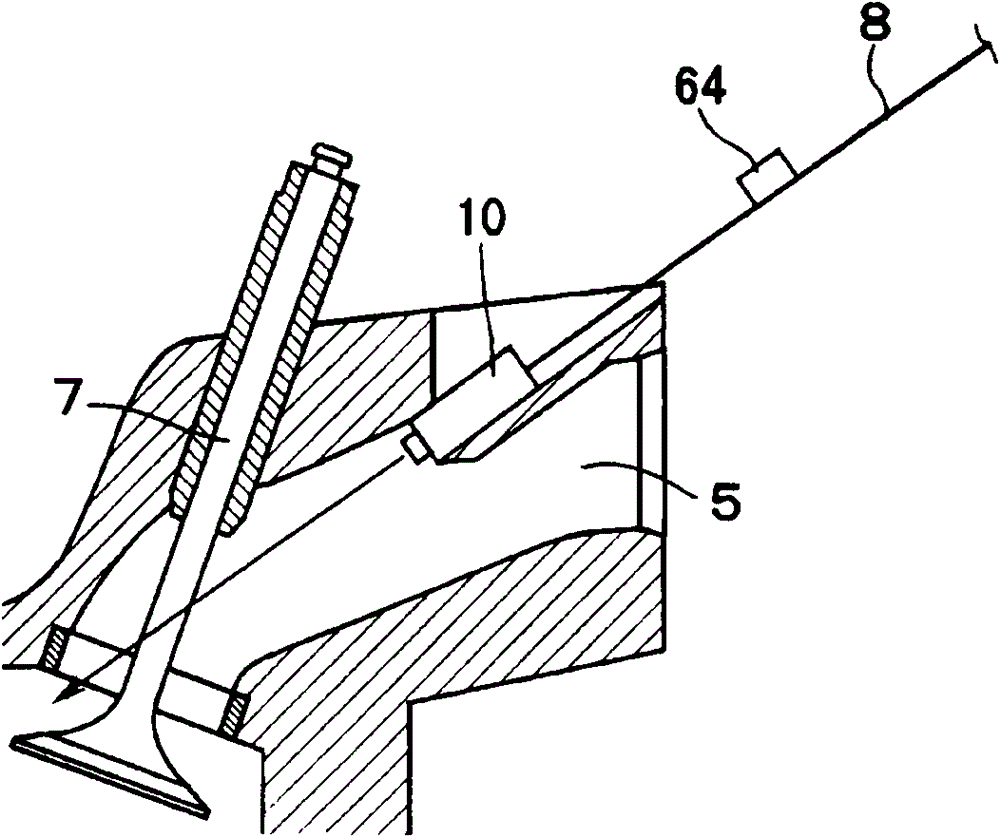

[0039] figure 1 shows a schematic block diagram of an entire internal combustion engine according to an embodiment of the present invention, and figure 2 The structure around the air intake is shown.

[0040] according to figure 1 and figure 2As shown, for each cylinder, a spark plug 3 is engaged to a cylinder head 2 of an engine body 1 (hereinafter, referred to as "engine") as an internal combustion engine, and an ignition coil 4 outputting a high voltage is connected to the spark plug 3 . Further, intake ports 5 (intake passages) are formed in the cylinder head 2 of each cylinder, and intake valves 7 are mounted on the combustion chamber 6 side of each intake port 5, respectively. The intake valves 7 are opened and closed following a cam of a camshaft (not shown) that rotates according to the rotation of the engine, thus allowing communication and / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com