Eccentrically swing type reduction gear

A technology of eccentric swing and reducer, which is applied in the direction of mechanical equipment, transmission devices, gear transmission devices, etc., and can solve the problems of inability to fully replace new grease, difficulty in passing grease, and difficulty in spreading grease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, an eccentric oscillating type speed reducer 100 according to an example of an embodiment of the present invention will be described in detail with reference to the drawings.

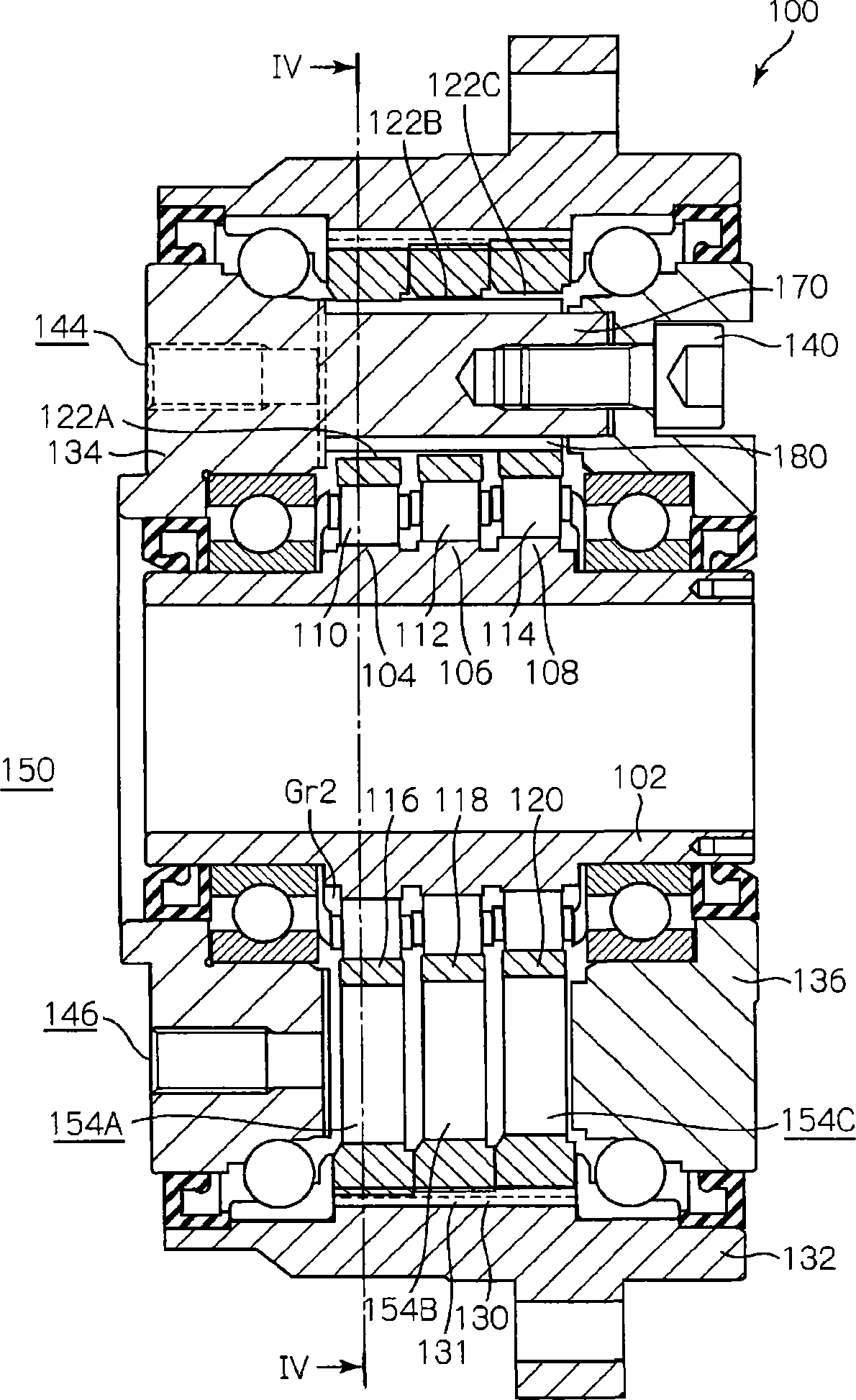

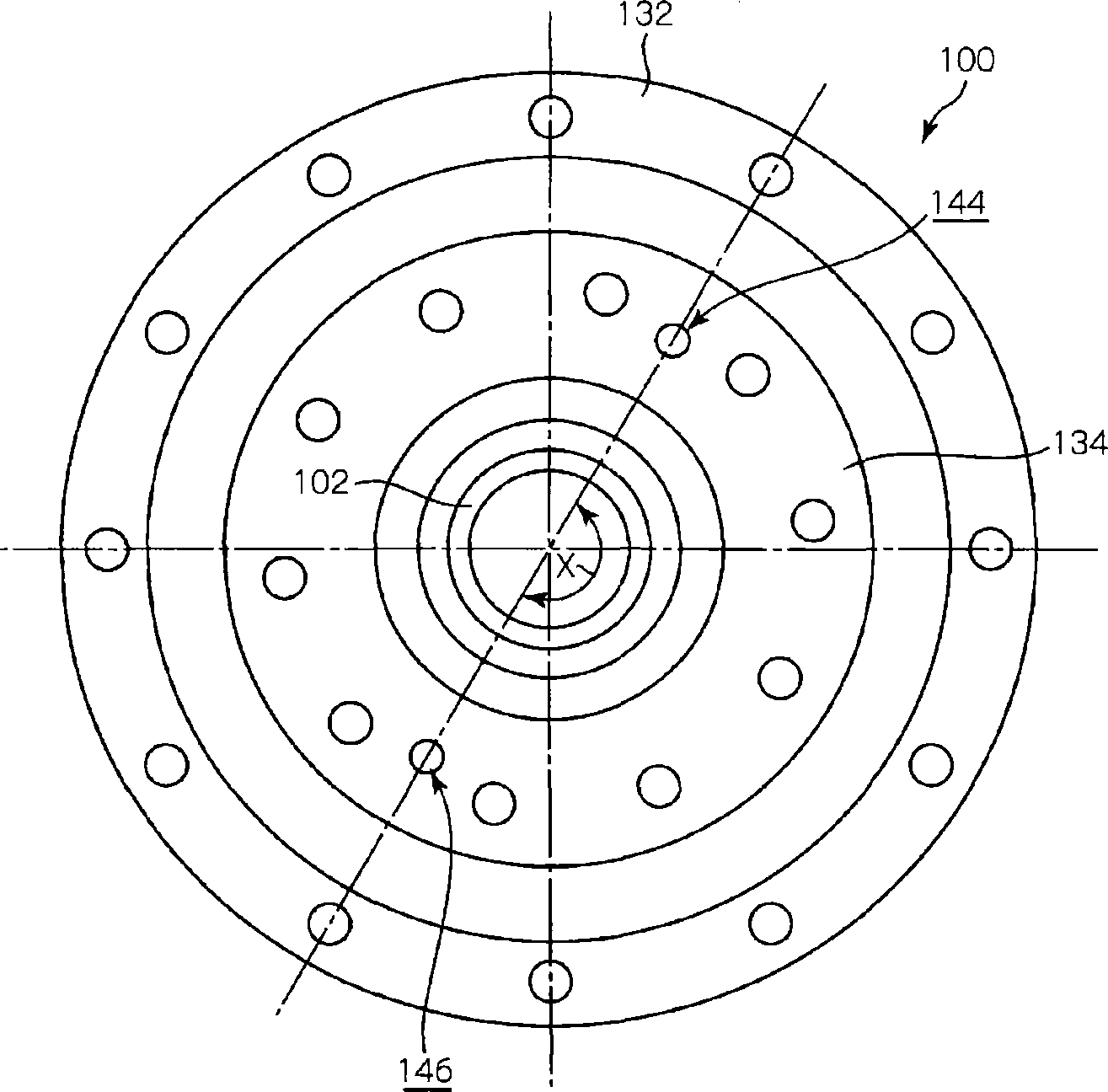

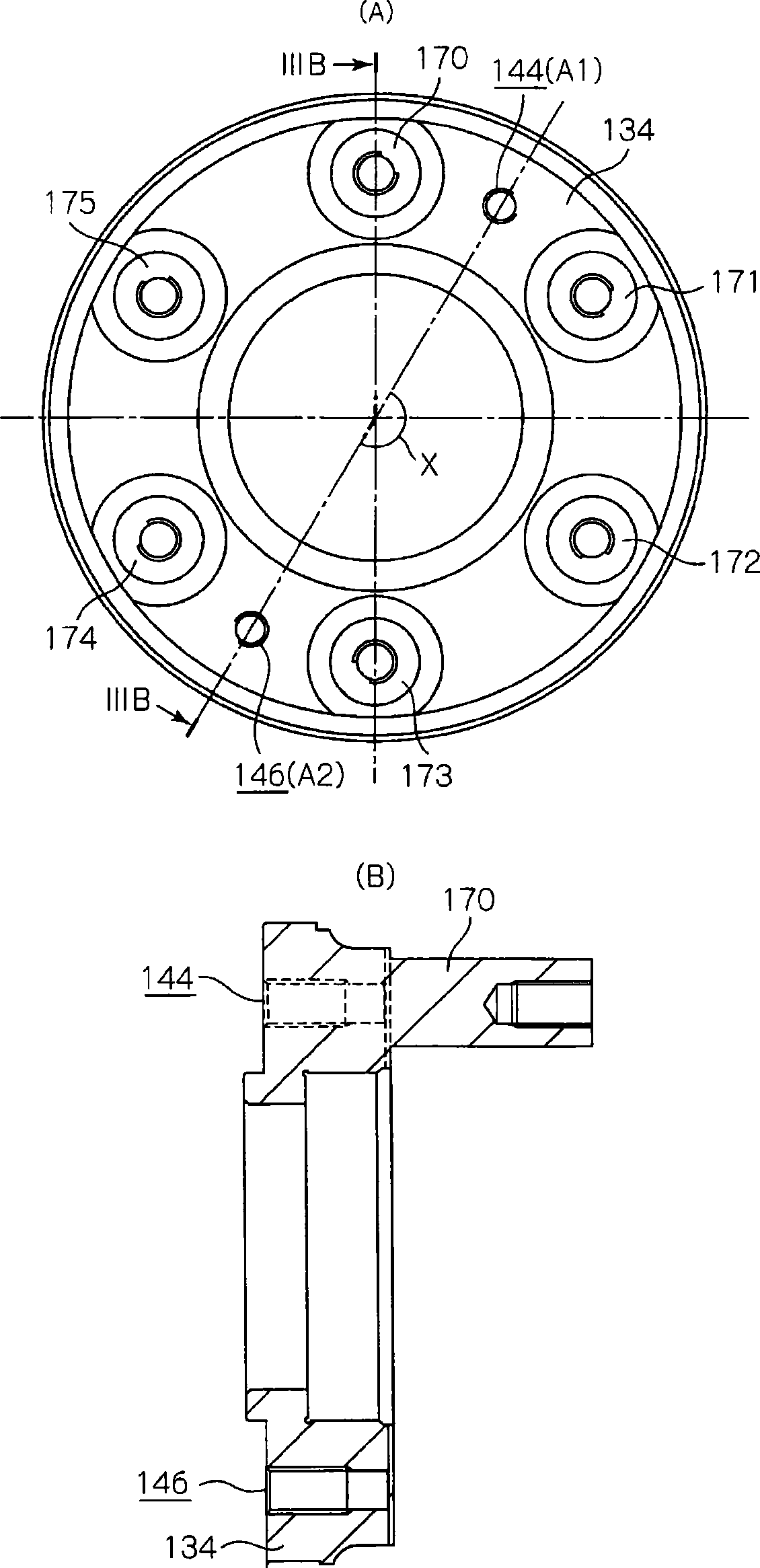

[0026] figure 1 It is a longitudinal sectional view of the eccentric oscillating speed reducer 100 . and, figure 2 yes means figure 1 The front view of the positions of the grease supply and discharge ports 144 and 146 in the reduction gear 100 is shown. image 3 Viewed from the side of the first external gear 116 figure 1 The rear view of the first flange body 134 provided in the shown reducer 100 ( image 3 (A)) and along image 3 The cross-sectional view of the arrow IIIB-IIIB line of the first flange body 134 shown in (A) ( image 3 (B)). Figure 4 is along figure 1 It is a sectional view of the arrow IV-IV line of the reduction gear 100 shown.

[0027] First, the overall structure of the eccentric oscillating speed reducer 100 will be described.

[0028] The eccent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com