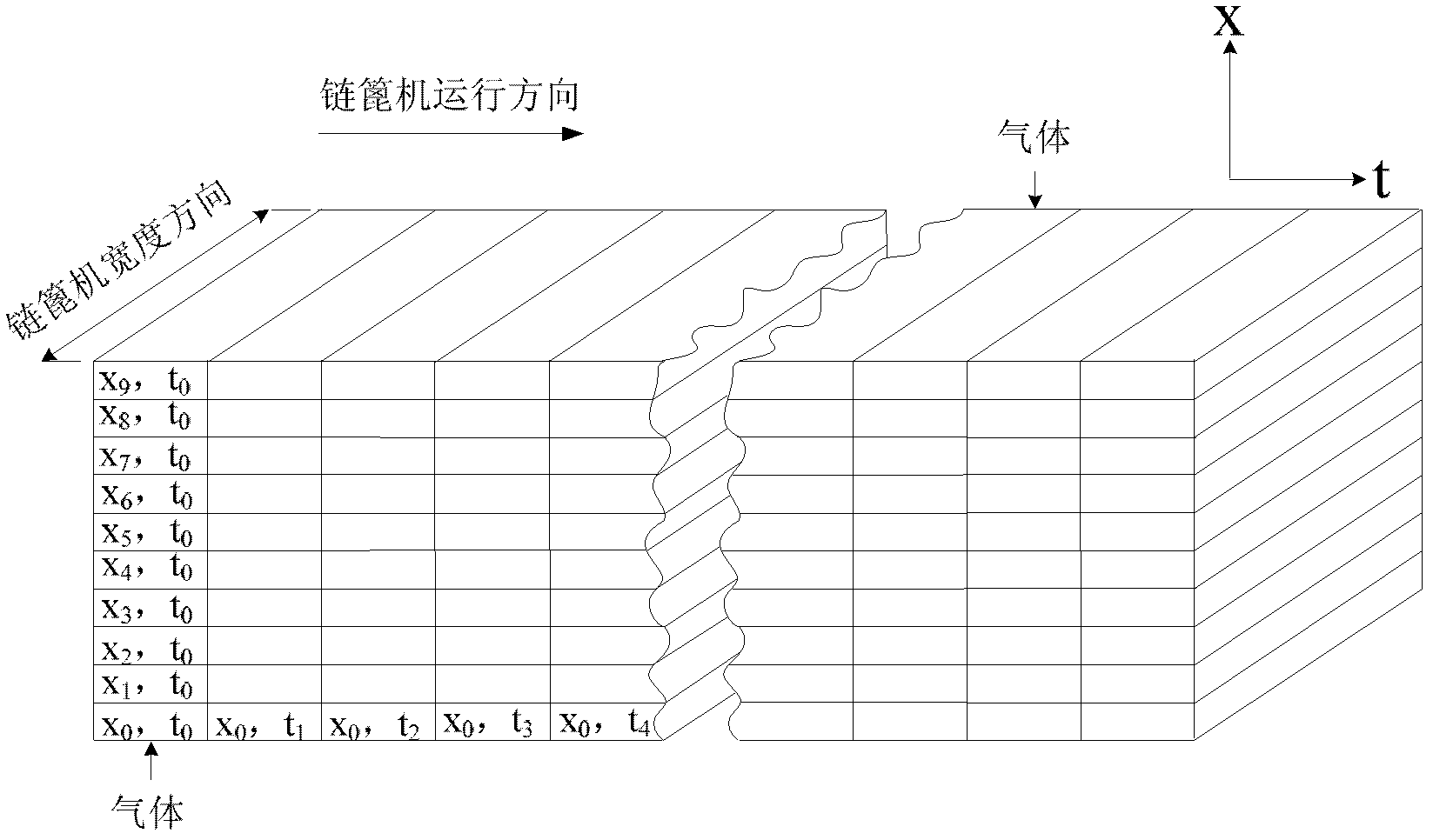

Method for detecting moisture distribution at material layer in chain grate machine in pelletizing production process

A production process and detection method technology, applied in the field of iron and steel metallurgy, can solve the problems of reduced productivity, uneven quality of finished balls, and difficulty in direct detection of water content changes in the material layer, and achieve the effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

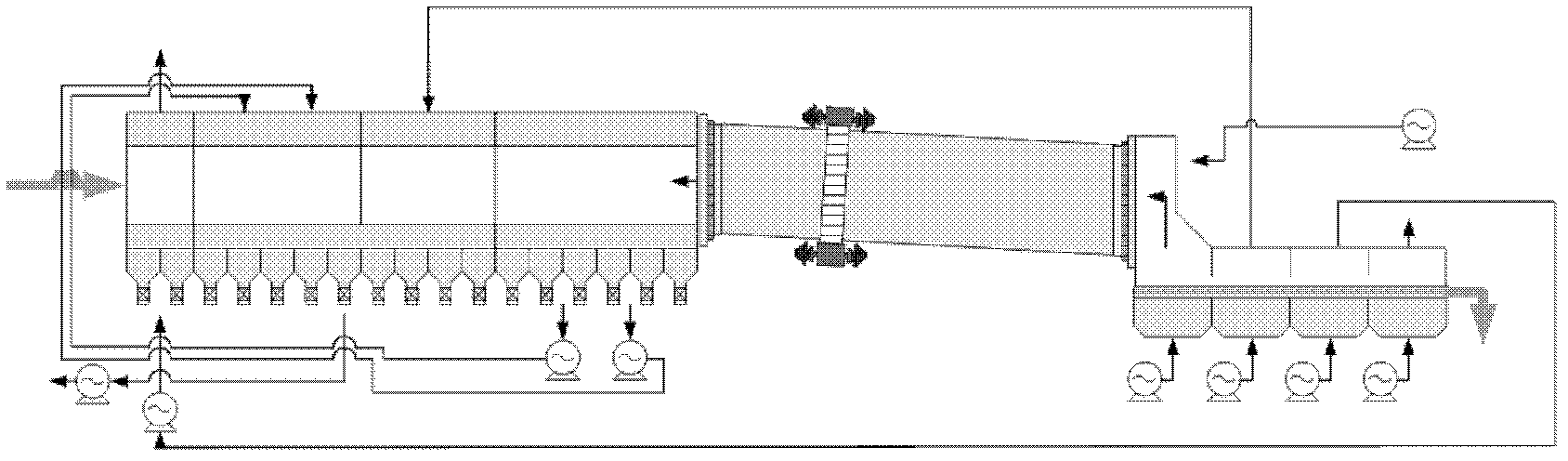

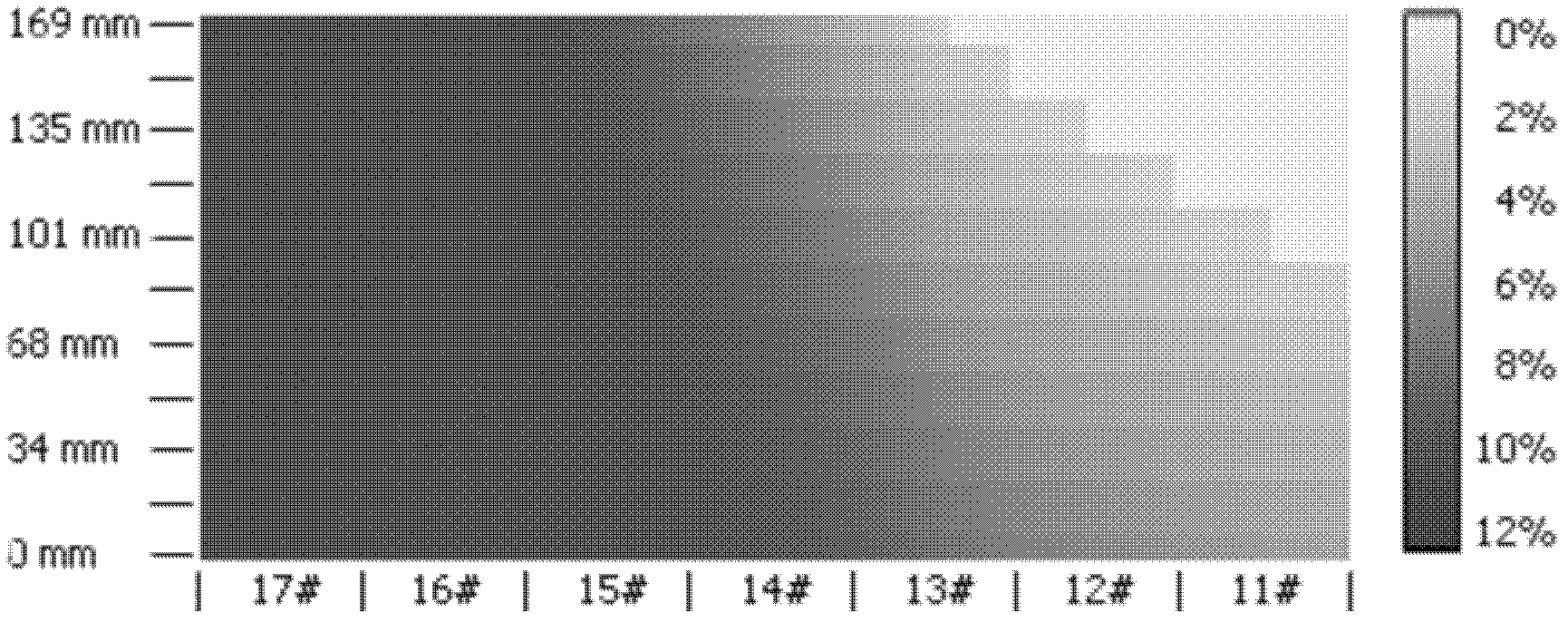

[0072] as if figure 2 In the typical chain grate-rotary kiln iron ore oxidation pellet production process shown, online detection of the moisture distribution of the material layer in the drying process of the chain grate is taken as an example, and the specific embodiments of the present invention are further described with reference to the accompanying drawings. This example is intended to further illustrate the invention, but not to limit the scope of the invention.

[0073] In the example, the effective length of the chain grate machine studied is 50m, the width is 4.5m, and the design cloth height is 0.2m. It is divided into blast drying section, exhaust drying section, preheating section I, and preheating section II. ~16#, 15~11#, 10~7# and 6~1#, of which the 10# bellows is 2m long, and the other bellows are 3m long.

[0074] Collect the real-time data of the required pellet production, as shown in Table 1.

[0075] Table 1 Production data collection

[0076]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com