Method for manufacturing a long micro lens array

A technology of microlens array and microlens, which is applied in the direction of microlithography exposure equipment, exposure device of photolithography process, photoplate process of pattern surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] 1. Optical Integrator

[0081] The general structure and function of the optical integrator according to the present invention will be described below.

[0082] 1.1 General structure

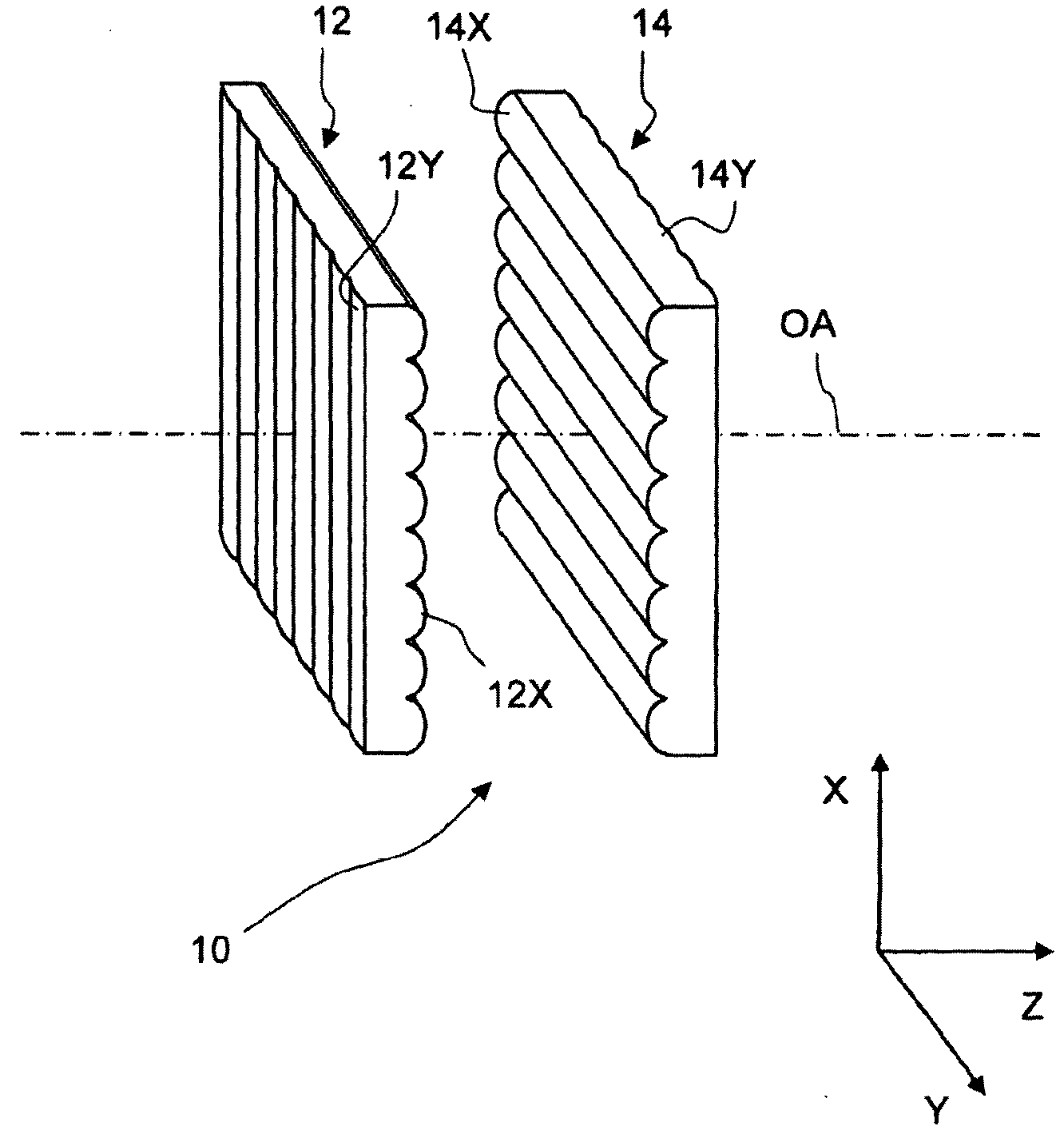

[0083] figure 1 is a perspective view of a simplified optical integrator, denoted by 10 as a whole. The optical integrator 10 of this embodiment is composed of a first integrator part 12 and a second integrator part 14 . The first integrator component 12 comprises a first array of cylindrical microlenses 12Y having parallel longitudinal axes aligned along the X direction. The first integrator component 12 also includes a second array of cylindrical microlenses 12X having parallel longitudinal axes aligned along a Y direction perpendicular to the X direction. Because the longitudinal axes of the microlenses 12X, 12Y are straight lines, the first microlens 12Y has refractive power only along the Y direction, while the second microlens 12X has refractive power only in the X direction.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com