Control device of spray electromagnetic valve in coal yard

A technology for control devices and solenoid valves, applied to valve devices, valve operation/release devices, valve details, etc., to achieve enhanced accuracy, reduced wiring costs, and simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1

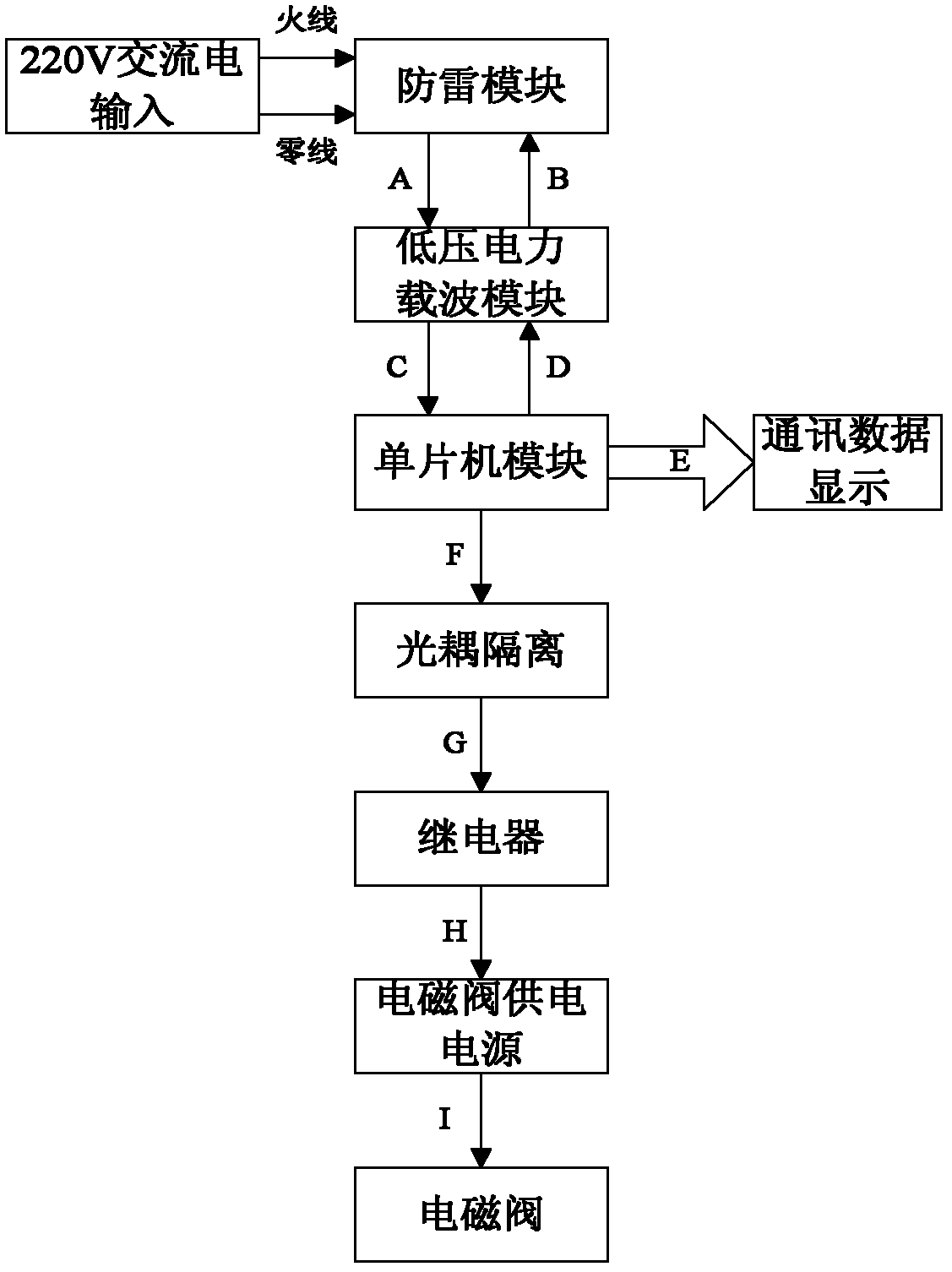

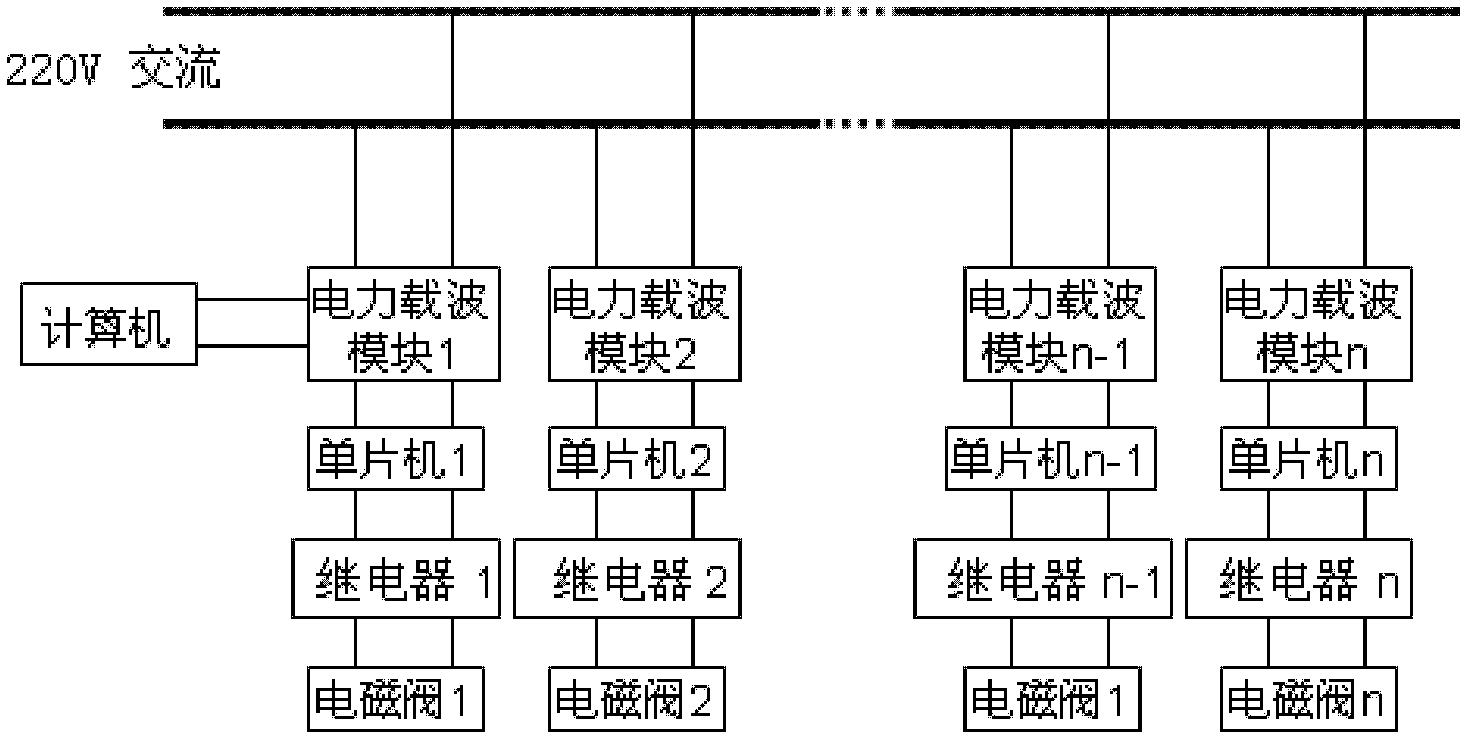

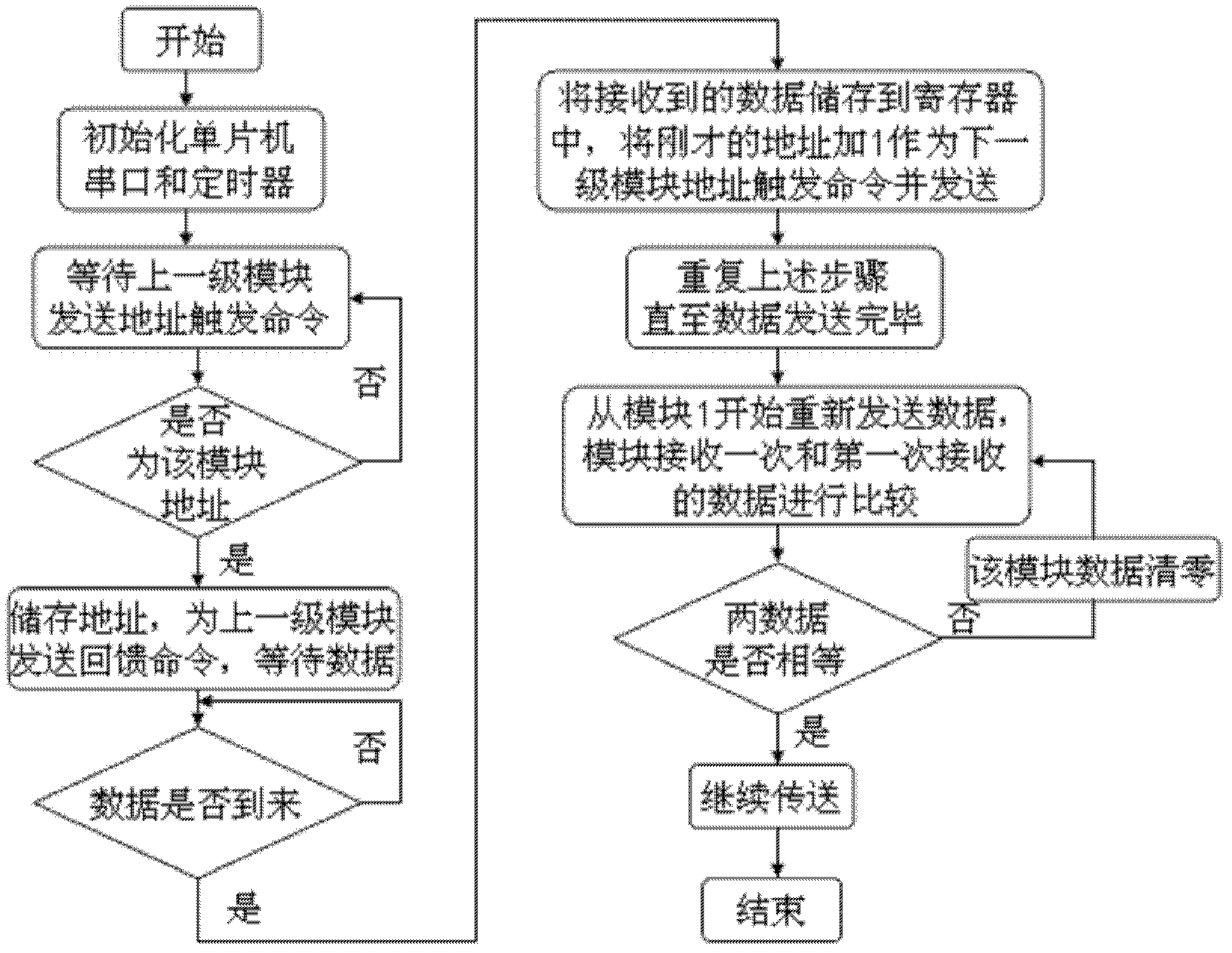

[0026] Such as figure 1 As shown, the control device of the coal yard spray solenoid valve provided by the present invention includes: a lightning protection module, a low-voltage power carrier module, a single-chip microcomputer module, a relay and a solenoid valve. The low-voltage power carrier module is connected to the 220V power supply line through the lightning protection module. At the same time, the low-voltage power carrier module is connected with the single-chip module, which is connected to the relay and solenoid valve in turn; the low-voltage power carrier module is used to complete the transmission and reception of control signals, and the single-chip module is used to control signal processing and trigger the opening and closing of the relay. The output terminal is connected with the solenoid valve to control the opening and closing of the solenoid valve.

[0027] An optocoupler isolation circuit is connected between the single-chip microcompute...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap