Groove milling method for producing IC (Integrated Circuit) intelligent card

A smart card and groove milling technology, applied in the information field, can solve problems such as low production efficiency, slow production speed, and high product rejection rate, and achieve the effect of improving machine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0044] The present invention will be further described in detail below in conjunction with the drawings.

[0045] Because the traditional slot milling process has a poor effect on the production of dual-interface smart cards, especially for the production method of dual-interface smart cards that use ultra-thin antennas instead of ultrasonic-wound antennas, the process of milling slots cannot even be completed. Because the thickness of the metal antenna is not greater than 0.03mm, and the thickness of the electroplated copper antenna is even 0.01mm, no matter whether it is a domestic or imported machine, it is impossible to complete the milling work.

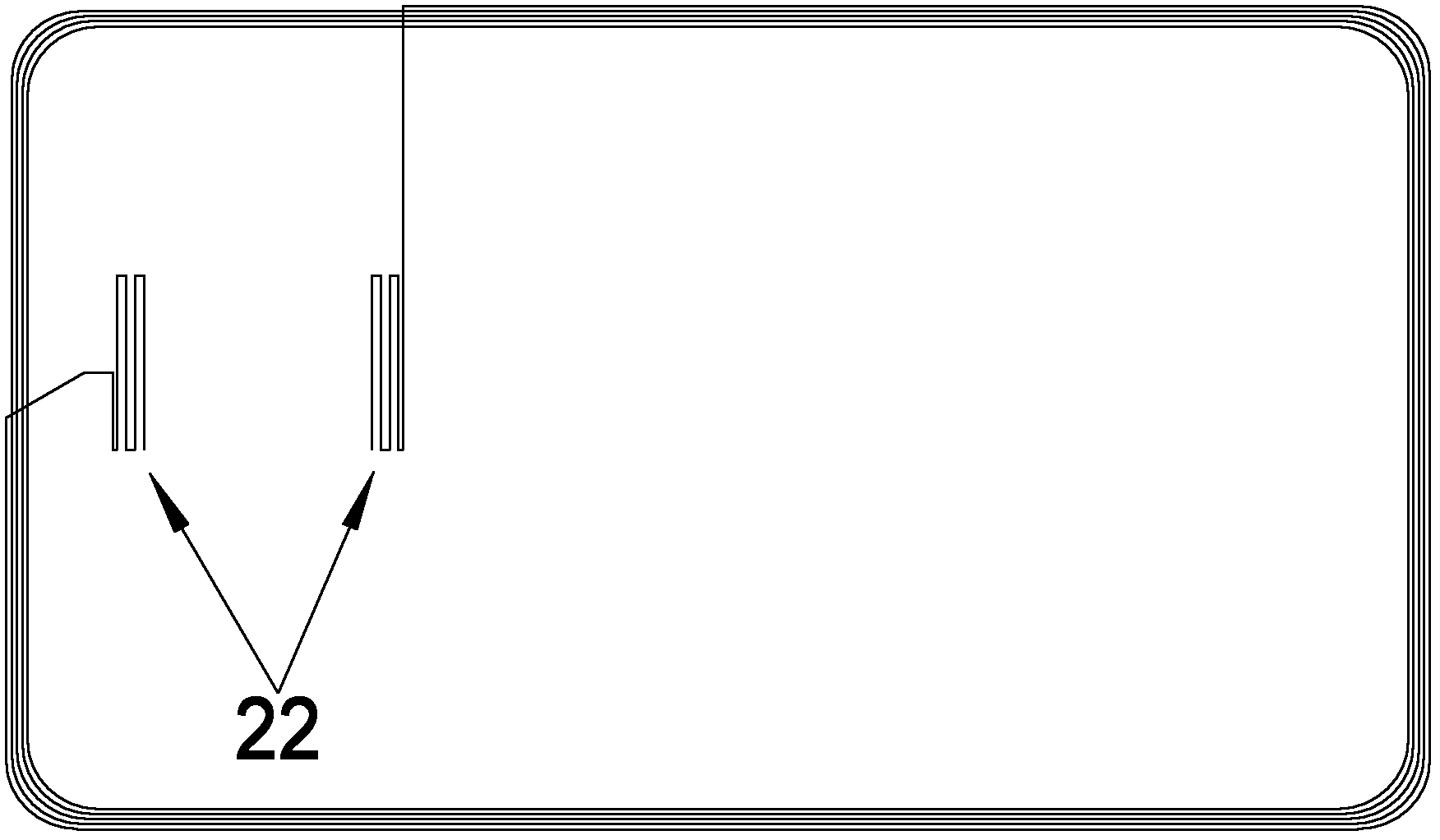

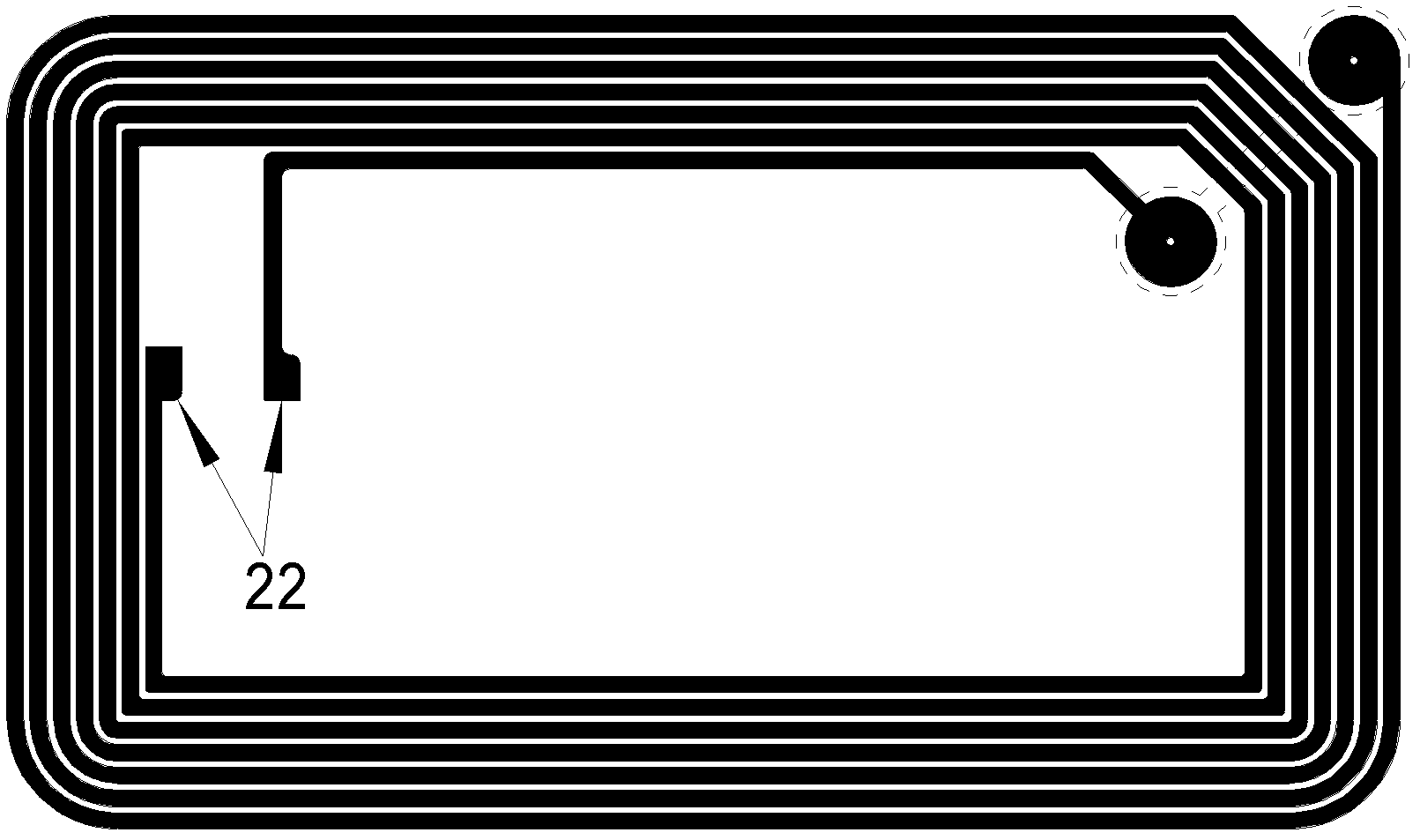

[0046] For this kind of dual-interface smart card, the manufacturing method includes: first, use etching, electroplating or printed antenna as the antenna layer; next, stack the other components of the card base in order, and laminate them, The large semi-finished product is put into the card punching machine and punched into a stand...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap