Coaxial connector for inspection

A technology for coaxial connectors and housings, which is applied in the field of coaxial connectors for inspection, and can solve problems such as the durability of coaxial connectors 101, and achieve excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

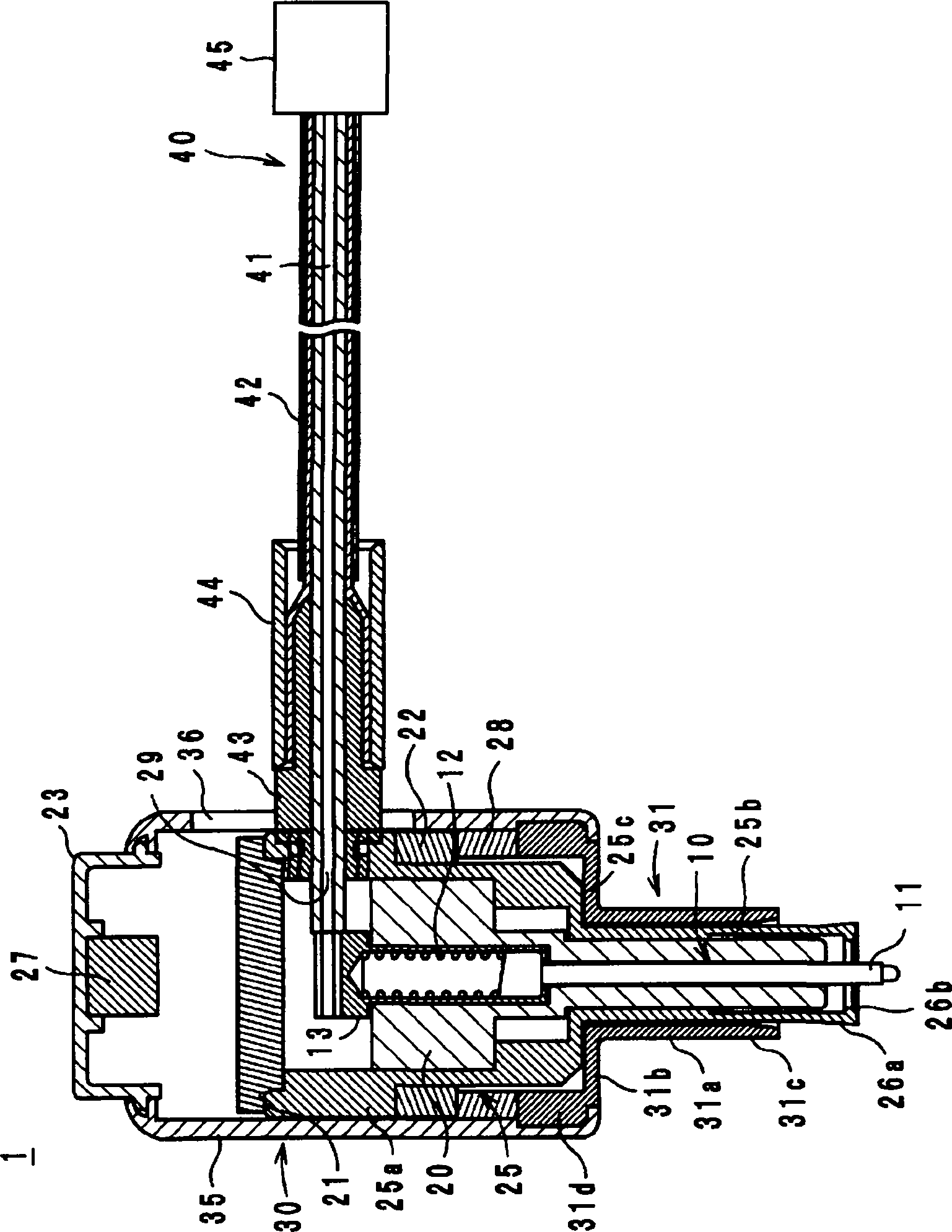

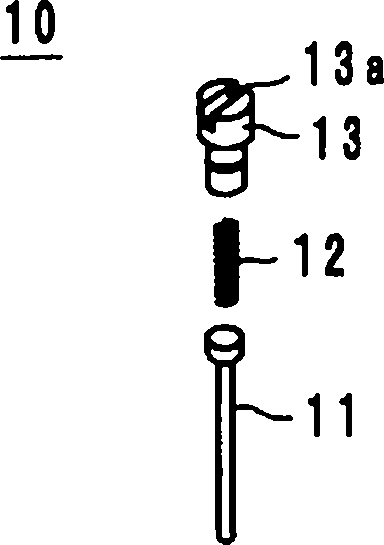

Method used

Image

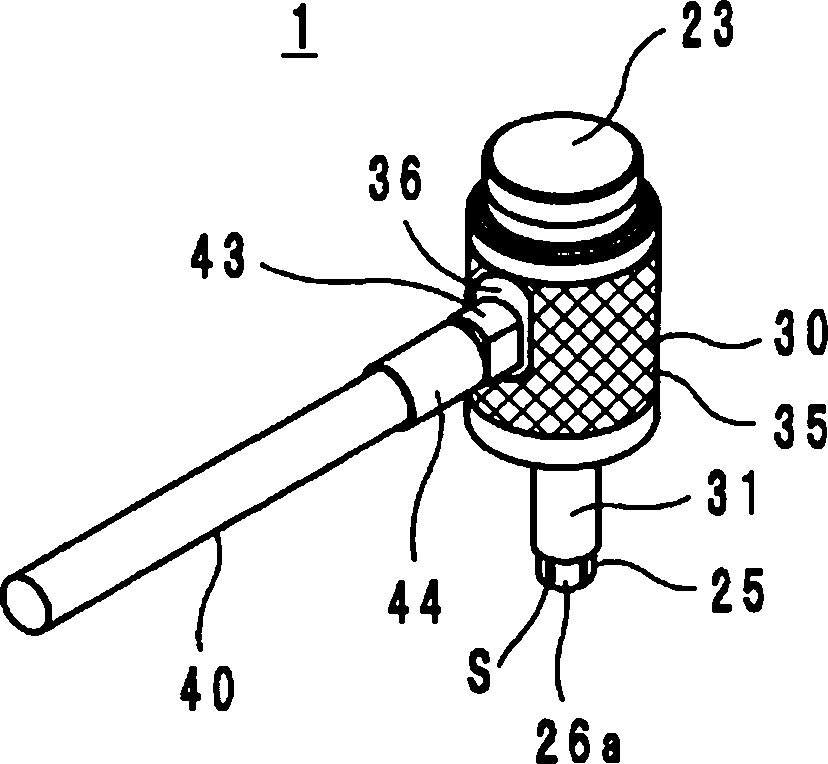

Examples

other Embodiment approach

[0075] In addition, the coaxial connector for inspection is not limited to the coaxial connector for inspection 1 according to the above-mentioned embodiment, and various changes can be made within the scope of the gist.

[0076]In the inspection coaxial connector 1, the yoke 23 and the magnet 27 are mounted on the sleeve 30, and the disk 21 is mounted on the housing 25, but the installation positions of the yoke 23, the magnet 27, and the disk 21 are not limited to this. For example, the yoke 23 and the magnet 27 may be attached to the housing 25 and the disk 21 may be attached to the sleeve 30 . However, since it is easier to press the flat disc 21 into the housing 25 than the cylindrical yoke 23 into the housing 25, it is preferable to install the yoke 23 and the magnet 27 on the sleeve 30, 25 install the disc 21.

[0077] In addition, in the coaxial connector 1 for inspection, the magnet 28 is attached to the sleeve 30 and the suction ring 22 is attached to the case 25, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com