Extraction process of effective ingredients from cordyceps mycelia

A technology of Cordyceps mycelium and active ingredients, which is applied in the direction of medical preparations containing active ingredients, organic active ingredients, plant/algae/fungus/moss ingredients, etc., which can solve the problem of easy damage, low extraction efficiency, and easy damage problems such as improving production efficiency, reducing production costs, and reducing the use of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Extraction of Cordyceps Mycelia Active Components

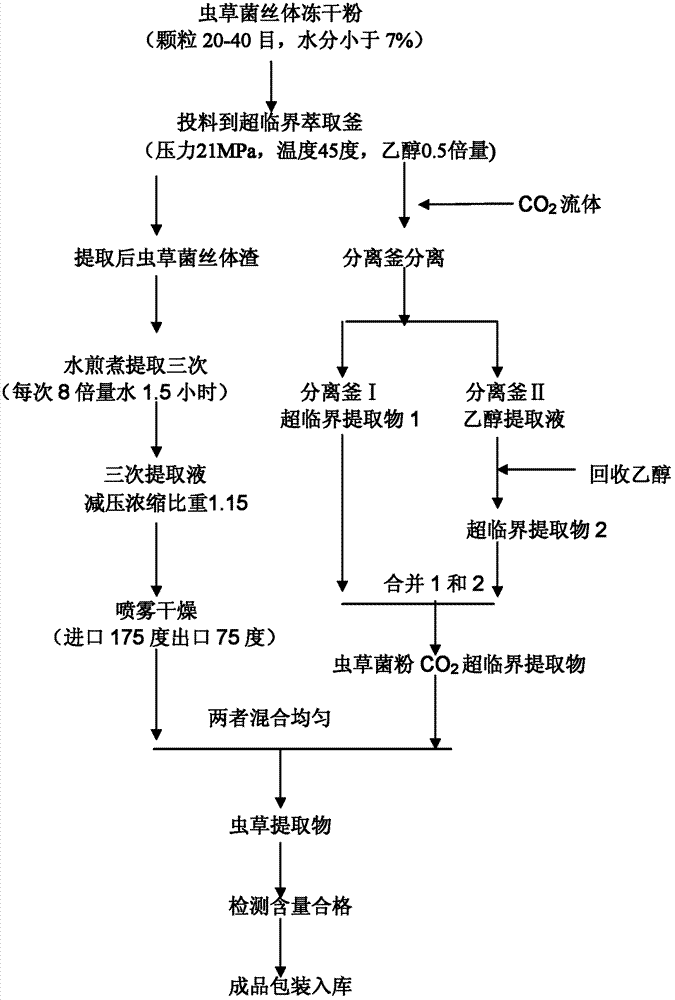

[0043] Such as figure 1 The extraction process flow chart of the shown Cordyceps mycelium active ingredient:

[0044] 1. The freeze-dried powder of Cordyceps mycelium is crushed into 20-40 mesh granules, weighed and put into the extraction kettle. It is required that the particles are uniform and the moisture content is not more than 7%.

[0045] 2. The carbon dioxide fluid is extracted for 3 hours, the pressure is 21 MPa, the temperature is 45 degrees, the amount of ethanol aqueous solution used as entrainer is 0.5 times the amount of mycelium, and the mass percentage concentration of ethanol in the ethanol aqueous solution can be 60-95%, which is more suitable The concentration is 95%.

[0046] 3. During the extraction, the separation tank is separated, the separation tank I discharges the extract, and the separation tank II discharges ethanol. Ethanol is recovered, and the residual extract is mixed wit...

Embodiment 2

[0058] Example 2 Extraction of Cordyceps Mycelia Active Components

[0059] 1. The freeze-dried powder of Cordyceps mycelium is crushed into 20-40 mesh particles, the amount of material is weighed, the same amount as in Example 1, and put into the extraction kettle. It is required that the particles are uniform and the moisture content is not more than 7%.

[0060] 2. Carbon dioxide fluid extraction for 2-3 hours, the pressure is controlled at 18-26MPa, the temperature is controlled at 35-50 degrees, the amount of entraining agent ethanol aqueous solution is 0.5-3 times the amount of mycelia, and the mass percentage concentration of ethanol in the ethanol aqueous solution It can be 60-95%, a more suitable concentration is 95%.

[0061] 3. During the extraction, the separation tank is separated, the separation tank I discharges the extract, and the separation tank II discharges ethanol. Ethanol is recovered, and the residual extract is mixed with the extract of the separation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com