Method for manufacturing wind wheel blade by vacuum suction and injection

A technology of wind rotor blades and vacuum suction, applied in applications, household appliances, household components, etc., can solve problems affecting the quality of wind rotor blades, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

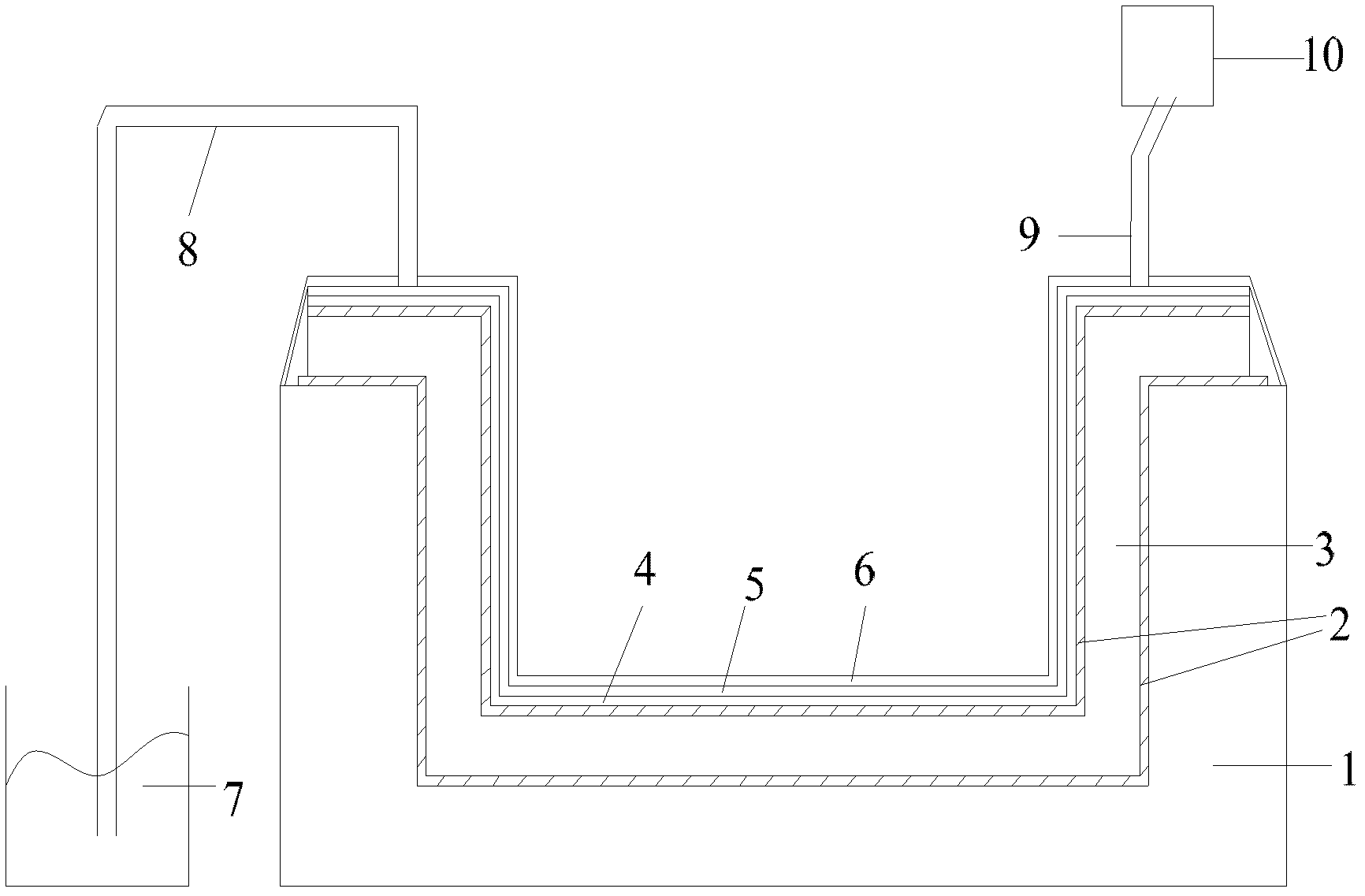

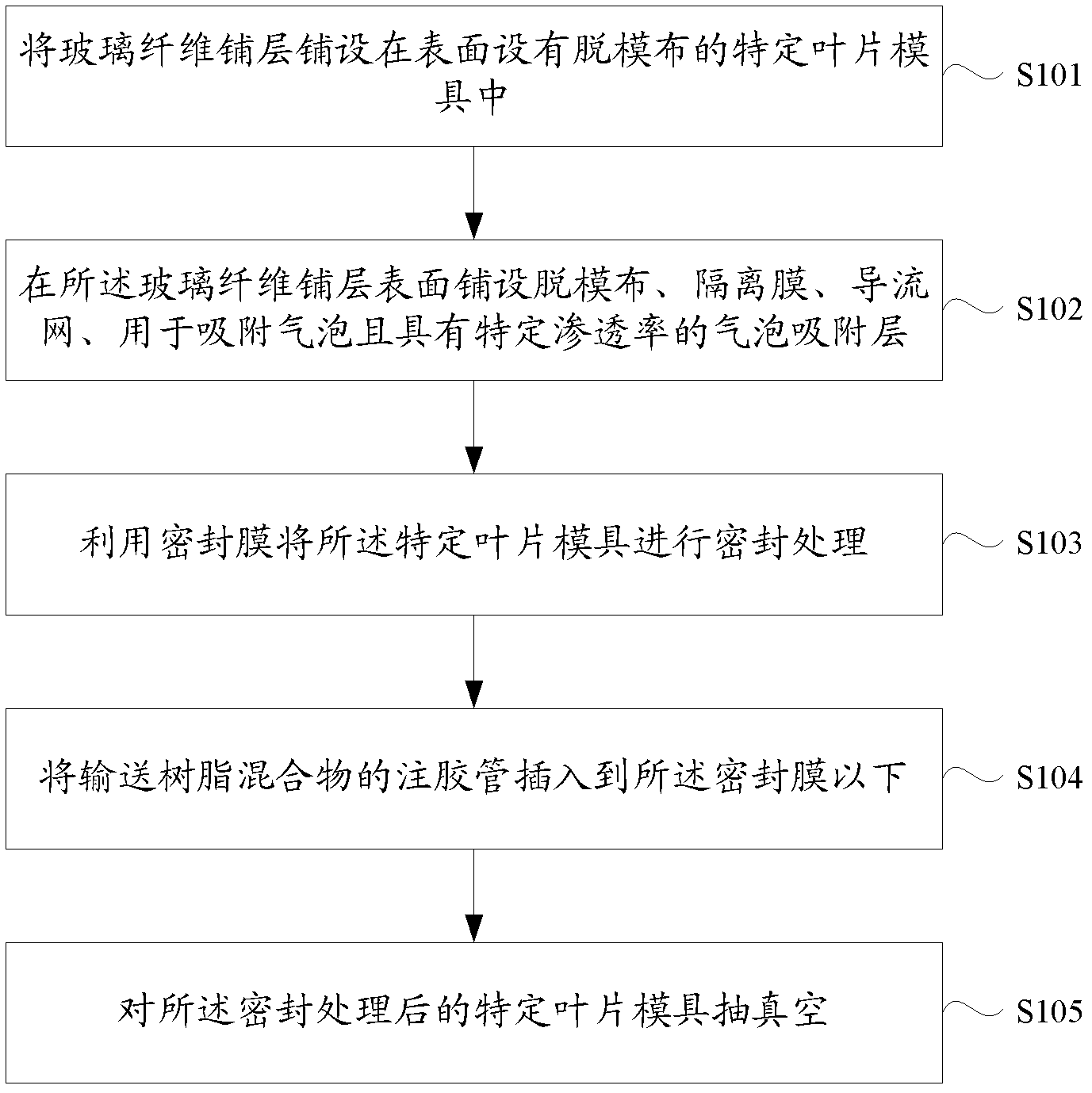

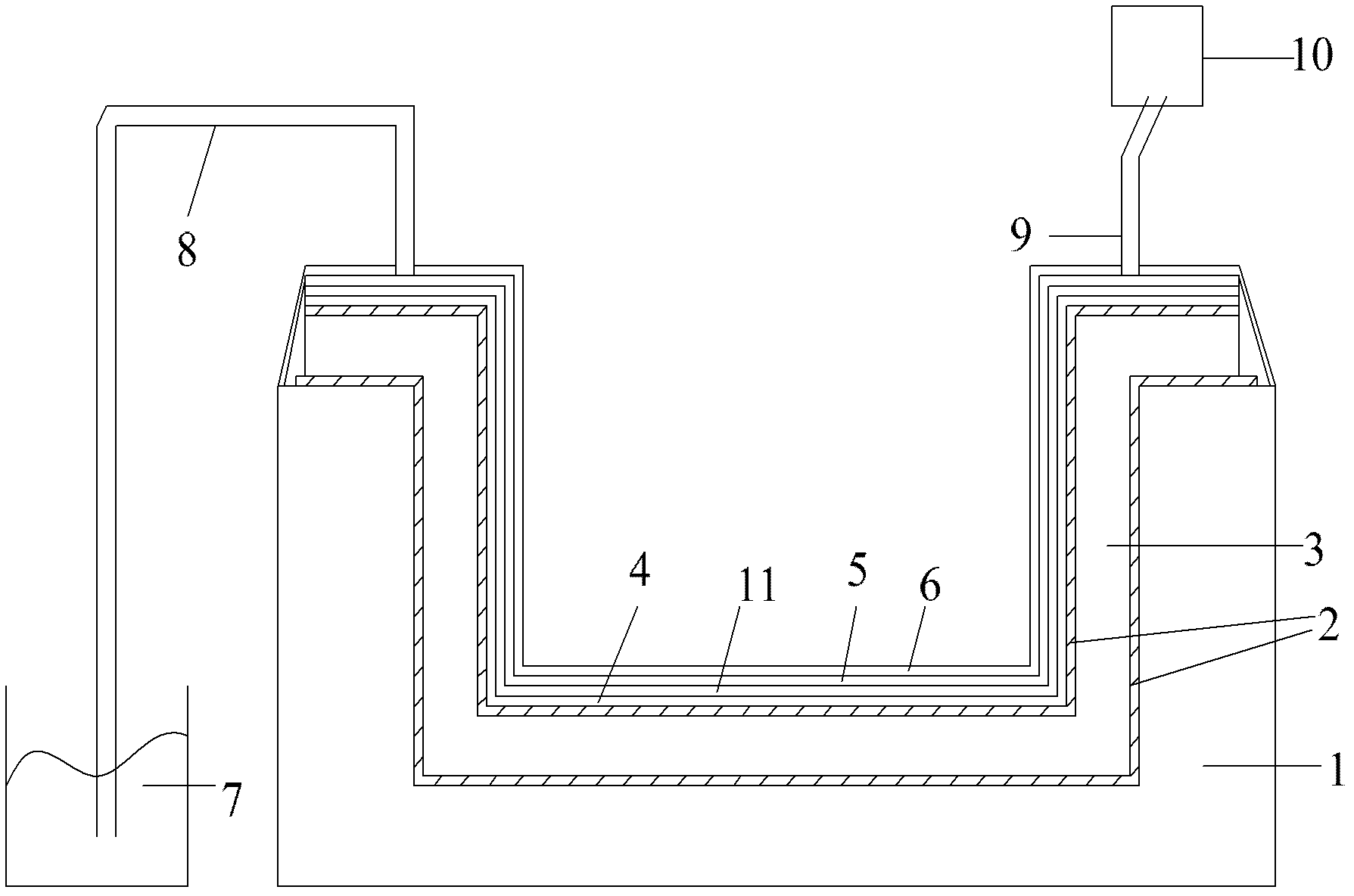

[0025] In order to solve the problem of low product quality caused by using vacuum injection to manufacture wind rotor blades in the prior art, an embodiment of the present invention provides a method for utilizing vacuum injection to manufacture wind rotor blades, the method comprising:

[0026] laying the glass fiber layup in a specific blade mold with a release cloth on the surface;

[0027] On the surface of the glass fiber layup, a release cloth, an isolation film, a flow guide net, and a bubble adsorption layer with a specific permeability for absorbing bubbles are laid;

[0028] Sealing the specific blade mold with a sealing film;

[0029] inserting the injection tube for conveying the resin mixture under the sealing membrane;

[0030] Vacuum the specific blade mold after the sealing process, so as to guide the resin mixture to be sucked and injected into the glass fiber layup under the action of vacuum negative pressure, and after curing, the required wind turbine bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com