Machine for renovating a track

A machine and machine frame technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of limited total length of machine frame and loss of frame length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

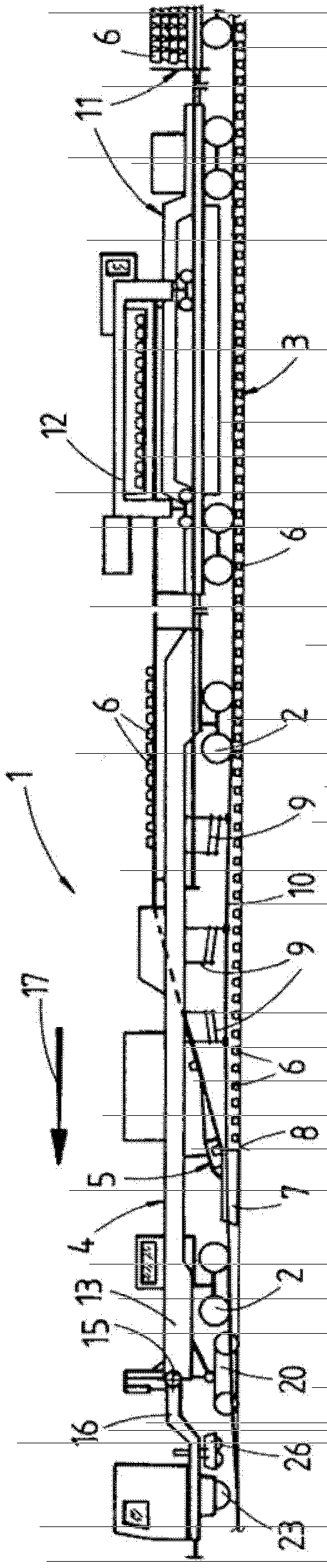

[0011] figure 1 The machine 1 shown in has a machine frame 4 that can be driven on a track 3 by means of a track running device 2 . Between the track running devices 2 , a device 5 for continuously laying new sleepers 6 is arranged on a track bed 8 leveled by plows 7 . Height-adjustable guides 9 are used to lift and place pre-placed rails 10 on sleepers 6 . Attached to the machine 1 are further carriages 11 for transporting the sleepers 6 and for accommodating a gantry crane 12 .

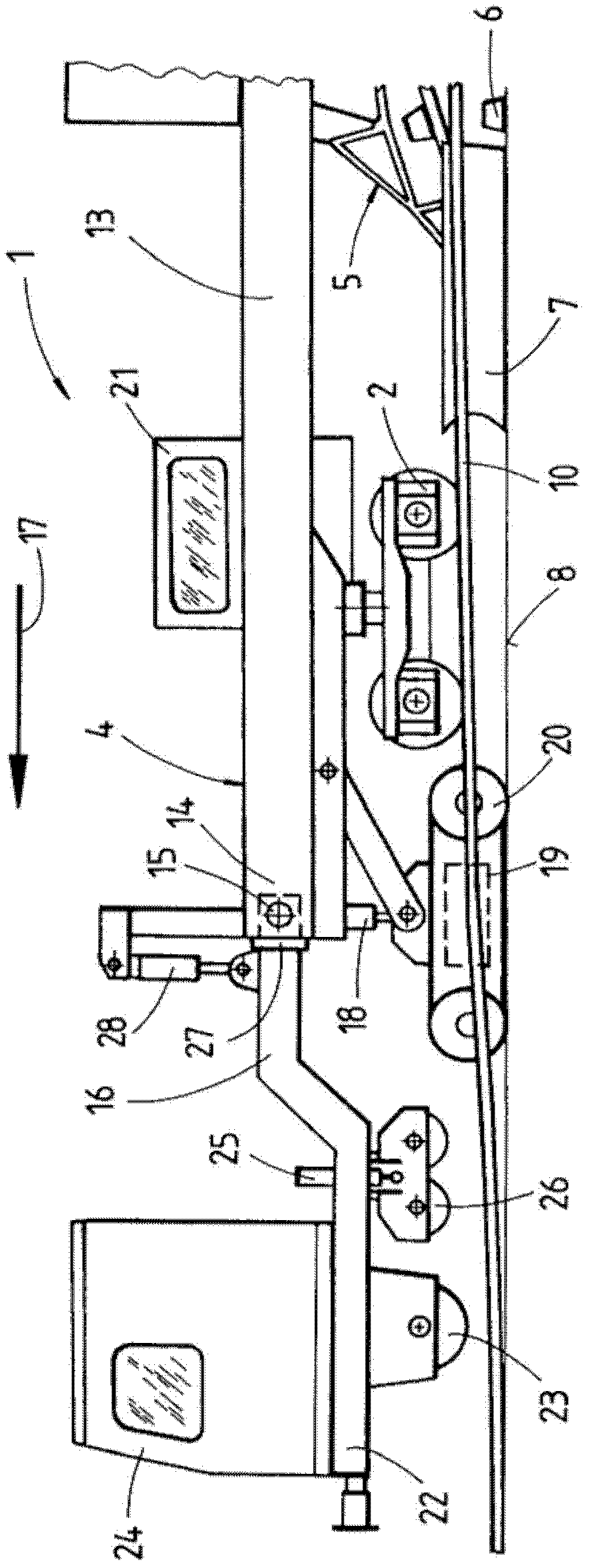

[0012] If especially also from figure 2 As can be seen, the machine frame 4 consists of a main frame 13 , each supported at the end by a two-axle track running device 2 , and an auxiliary frame 16 fixed to the front end 14 of the main frame in the working direction 17 via a hinge 15 .

[0013] Arranged on the front end 14 of the main frame 13 is a caterpillar 20 which is height-adjustable via a drive 18 and is equipped with a travel drive 19 . Immediately behind the tracked running gear 20 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com