Cylinder head set fitting

A technology of matching body and set, applied in the direction of cylinder head, cylinder, liquid variable capacity machine, etc., can solve the problems of increasing cost of effective connection, difficult processing, easy damage to cylinder head gasket, etc., to reduce volume and complexity, improve The effect of bearing pressure and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

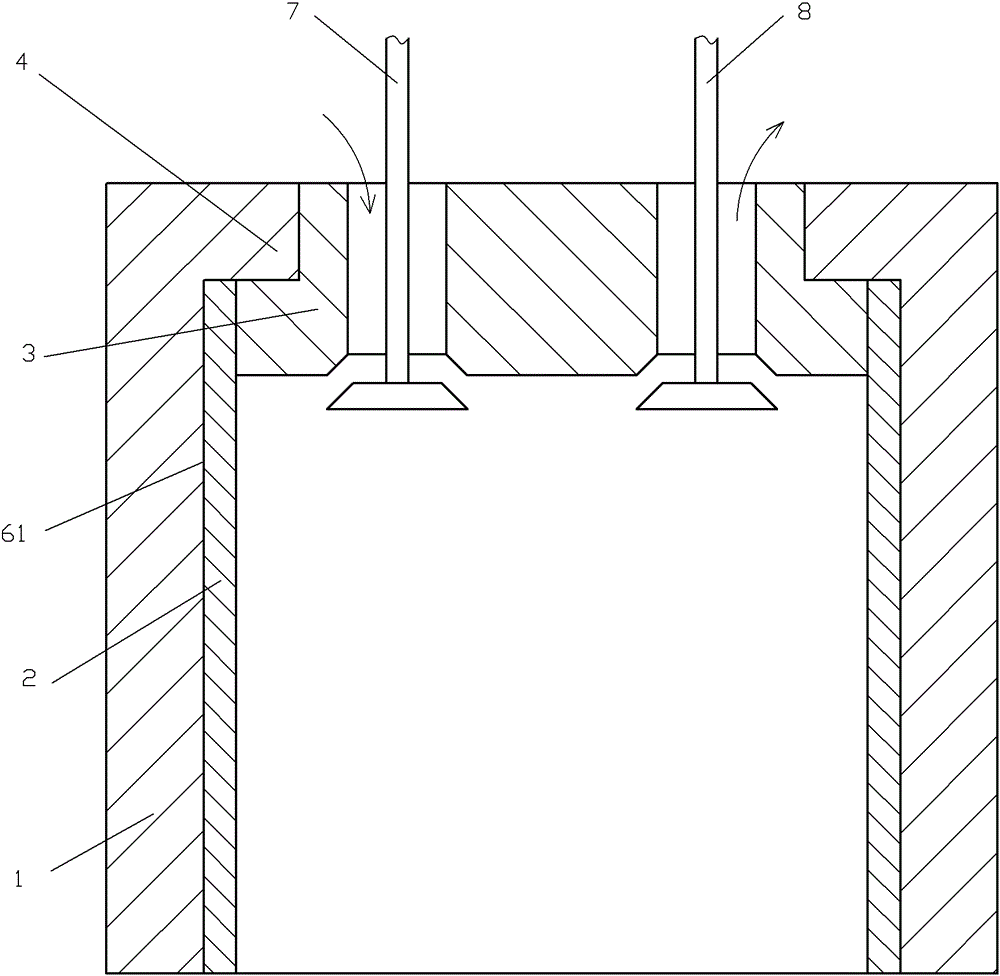

[0058] Such as figure 1 The shown cylinder head suiting body includes a body 1, a cylinder liner 2 and a cylinder head 3, a sealing bearing closing structure 4 is provided at the upper opening of the cylinder hole 61 of the body 1, and the cylinder head 3 is arranged on the The cylinder liner 2 is in bearing and sealing fit with the sealing bearing closing structure 4 , and the cylinder head 3 is provided with an intake valve 7 and an exhaust valve 8 .

[0059] In this embodiment, the installation method of the cylinder head 3 is different from the installation method of the traditional cylinder head. First, the cylinder liner 2 is pressed into place from the bottom of the cylinder hole 61, and then the cylinder head 3 is installed in place from the bottom of the cylinder hole 61. The bottom of the cylinder liner 2 is plugged into a position that is in sealing and bearing fit with the sealing and bearing closing structure 4 .

Embodiment 2

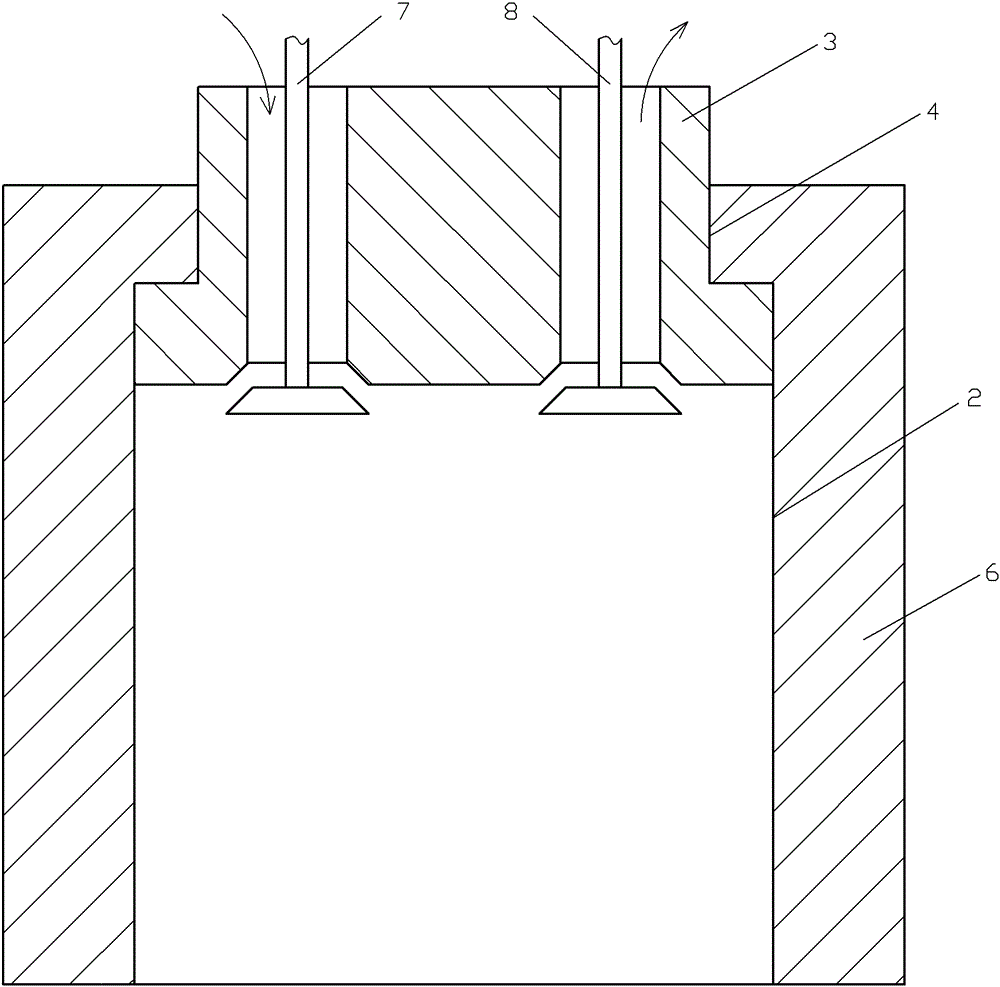

[0061] Such as figure 2 The shown cylinder head suit body includes a body-cover integrated body 6 and a cylinder head 3, and a sealing load-bearing closing structure 4 is provided at the upper opening of the cylinder liner 2 of the body-cover integrated body 6, and the cylinder head 3 It is arranged in the cylinder liner 2 of the body-cover integrated body 6 and is in load-bearing and sealing cooperation with the sealing bearing closing structure 4 , and an intake valve 7 and an exhaust valve 8 are arranged on the cylinder head 3 .

[0062] In this embodiment, the installation method of the cylinder head 3 is different from the installation method of the traditional cylinder head. Location.

Embodiment 3

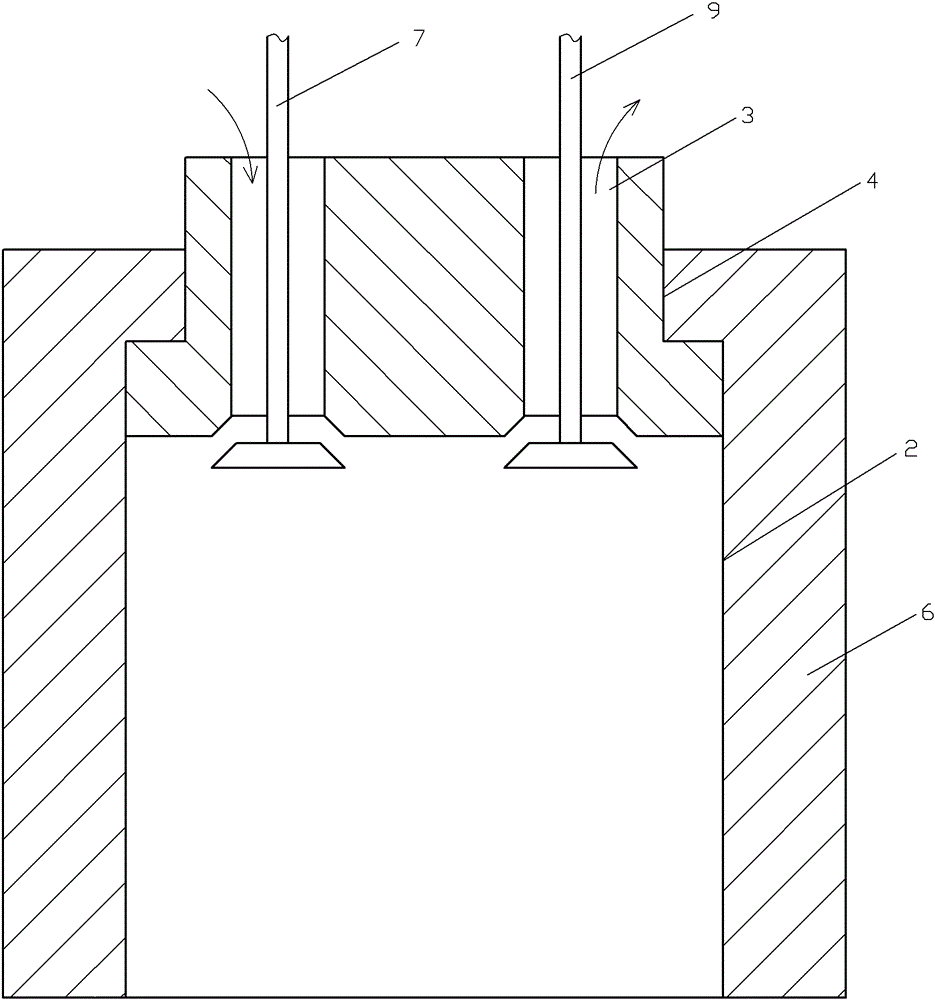

[0064] Such as image 3 The difference between the shown cylinder head fitting body and Embodiment 2 is that an intake valve 7 and an air supply valve 9 are provided on the cylinder head 3, and the cylinder head fitting body is used for a gas compressor to output compressed gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com