7/16 type radio frequency coaxial connector with airtight structure

A radio frequency coaxial, airtight technology, applied in the direction of connection, two-part connection device, contact parts, etc., can solve the problems of inability to guarantee the airtightness index, poor airtightness index of the connector, and low production efficiency, and achieve the guarantee The electrical performance index and assembly process are reasonable, the airtight performance is excellent, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

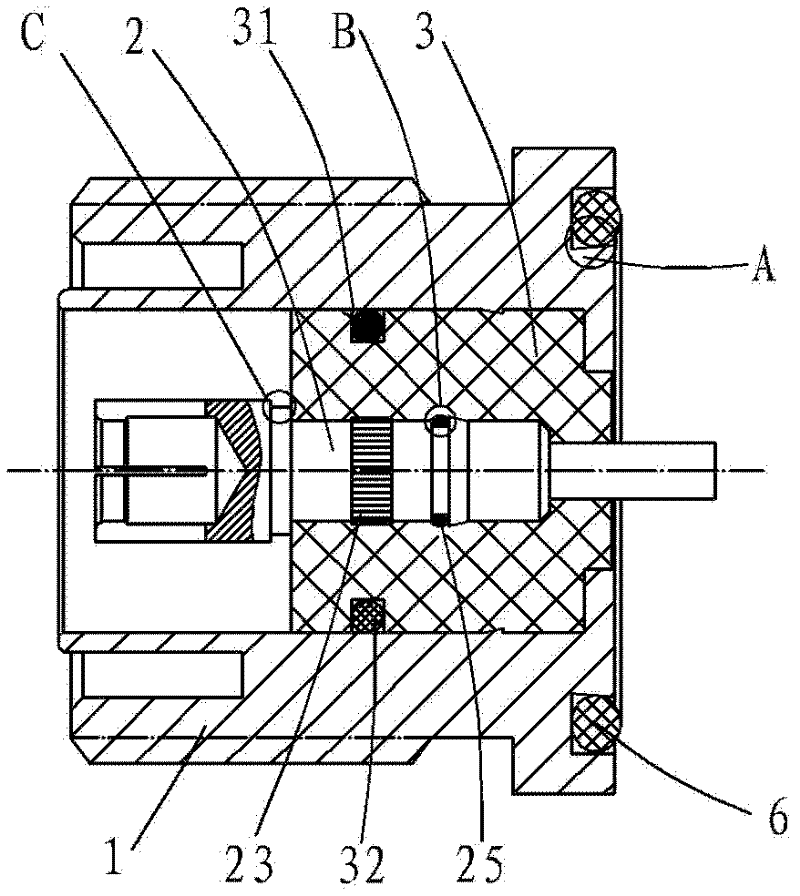

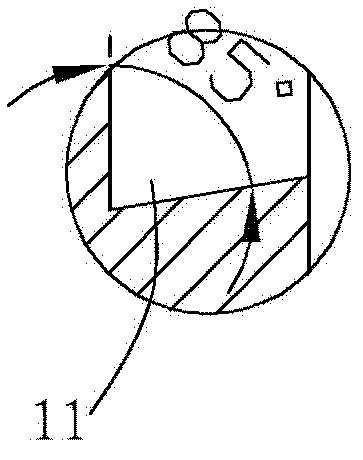

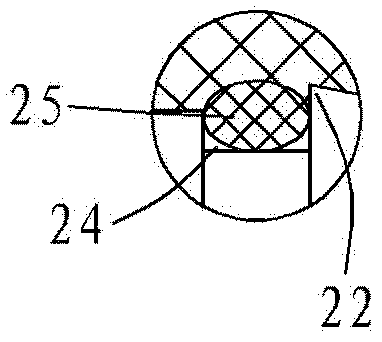

[0017] Example: see Figure 1-4 , the 7 / 16 type radio frequency coaxial connector of the airtight structure in this embodiment includes a central conductor 2, an insulating medium 3 and an outer conductor 1 which are arranged coaxially from the inside to the outside in order. In order to ensure the outer conductor 1 and the insulating medium The assembly between 3 is easy and the air tightness between the two is ensured. A first sealing groove 31 is arranged on the outer circumference of the insulating medium 3, and an interference fit with the inner cavity wall of the outer conductor 1 is arranged in the first sealing groove 31. the first sealing ring 32.

[0018] see figure 1 , 4 , a compensation ring 21 is provided at the transition of the central conductor 2 from the air medium to the insulating medium, which balances the uneven impedance of the transmission line and reduces the reflection loss at the transition. Specifically, the small end of the central conductor 2 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap