Rolling contact fatigue test method of small sample turnplate bearing

A technology of rolling contact fatigue and slewing bearings, which is applied in mechanical bearing testing and other directions, to achieve the effects of low cost, simple and easy testing, and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

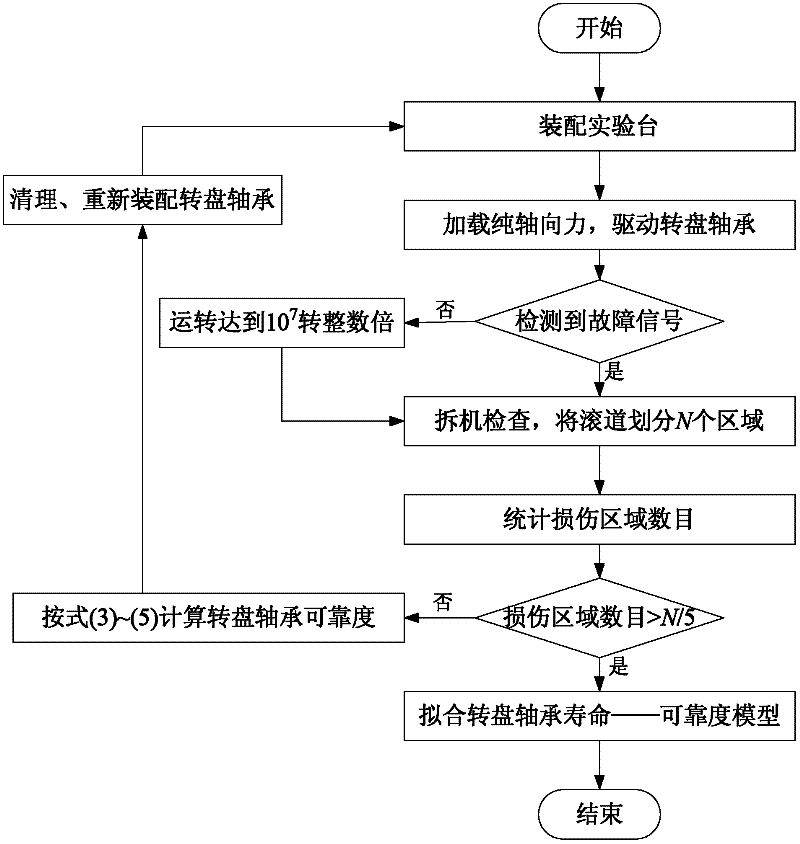

[0031] Such as figure 1 ,, Implementation steps:

[0032] The implementation process of the present invention is available figure 1 The schematic diagram shown in the description can be divided into the following steps:

[0033] (1) Assembly test bench;

[0034] (2) Apply a pure axial force between 0.25 and 2 times Ca to the slewing bearing to be tested to drive the slewing bearing;

[0035] (3) If a new fault signal is observed during the test, disassemble the machine for inspection and divide the raceway of the slewing bearing into several areas. 7 Disassemble and check when turning to integer multiples;

[0036] (4) Count the number of damaged areas of the inner and outer ring raceways;

[0037] (5) If the number of damaged areas is less than N / 5, calculate the reliability of the turntable bearing according to formulas (3) to (5), then re-clean and assemble the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com