Mold for producing inspection well base

A technology for inspecting wells and molds, applied in the field of molds, can solve the problems of lower production efficiency, inconvenient installation and disassembly of molds, etc., and achieve the effect of improving work efficiency and easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

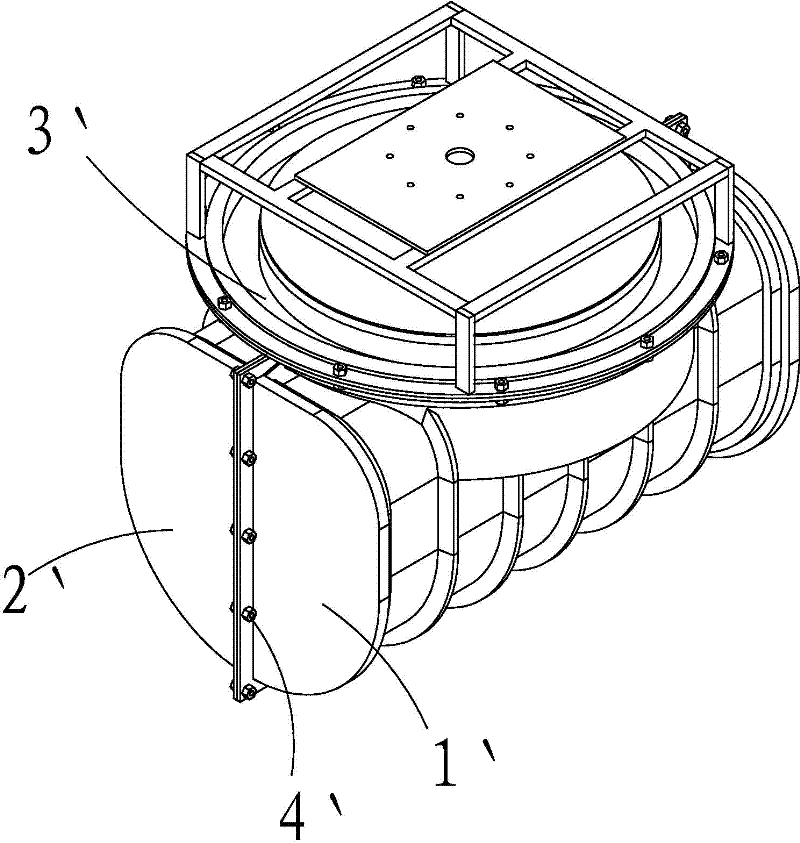

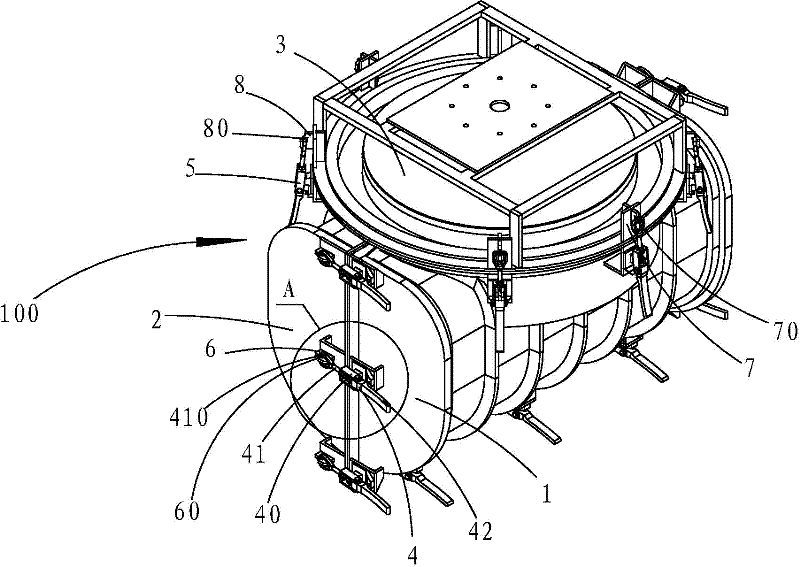

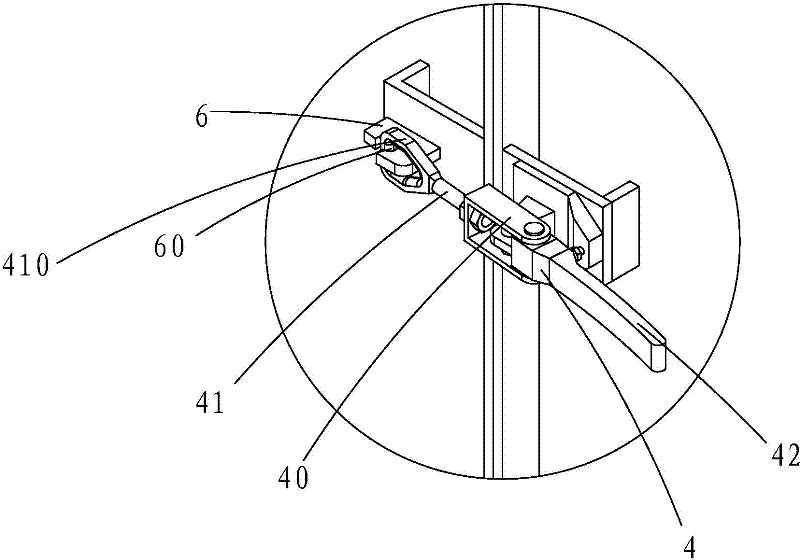

[0012] see figure 2 and image 3 , a mold 100 for producing an inspection well seat, which includes: a first mold body 1, a second mold body 2 and a mold cover 3, the first mold body 1 is equipped with several first hasps 4, the The second mold body 2 is equipped with several second hasps 5 and several first lock parts 6 matched with the first hasp 4, and the mold cover 3 is equipped with several locks 6 matched with the first hasp 4. The second locking member 7 and several third locking members 8 matched with the second hasp 5, the first hasp 4 is provided with a main body 40, a locking arm 41 mounted on one end of the main body 40 and The operating part 42 installed on the other end of the main body part 40, the operating part 42 can rotate relative to the main body part 40, the free end of the locking arm 41 is provided with a locking part 410, the structure of the second hasp 5 Same as the first hasp 4, the first locking member 6 is provided with a first locking groove ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap