Method and device for roasting sodium oxide by using shaft furnace

A roasting device and sodium oxide technology, applied in furnaces, vertical furnaces, furnace types, etc., can solve the problems of poor control of roasting temperature and atmosphere, large initial investment, low conversion rate, etc., to overcome the problems of kiln body The effect of ringing or rake teeth bonding accumulation, high vanadium conversion rate, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

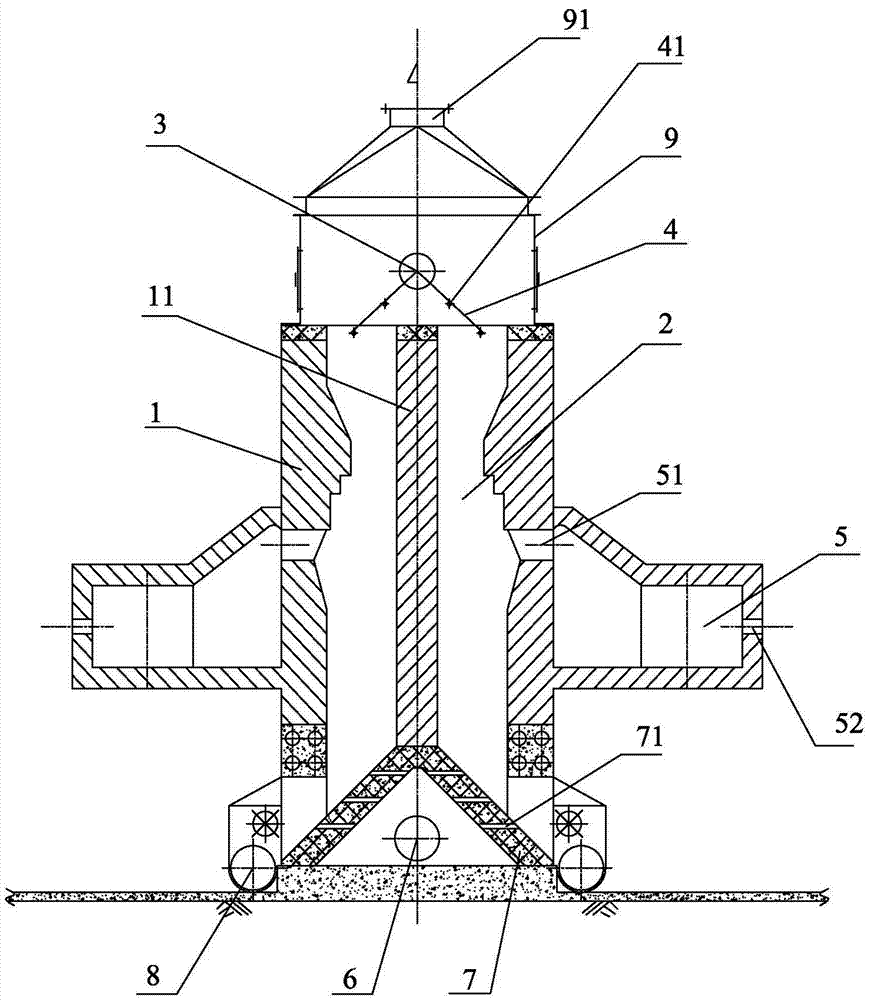

[0030] See figure 1 . The shaft furnace type sodium oxidation roasting device of the present invention comprises: a furnace wall brickwork body 1, a furnace chamber 2, a rotary feeder 3, a drying bed 4, a combustion chamber 5, a blower 6, a grating plate 7, a discharge device 8 and Smoke collection hood 9. in:

[0031] Furnace wall brick body 1 is arranged vertically. In this specific embodiment, the cross-section of the furnace-strength brickwork is rectangular. Furnace cavity 2 is surrounded by furnace wall brickwork and is vertically arranged. In this specific embodiment, the cross-section of the furnace cavity is also rectangular, and the size of the cross-section of the furnace cavity changes gradually from top to bottom along the height direction, such as tapering, constant, gradually expanding and tapering. The center of the furnace wall brick body 1 is provided with a diversion partition wall 11 that divides the furnace wall brick body into two. The furnace chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com