Driving belt and manufacturing method thereof

A manufacturing method and transmission belt technology, which can be applied to belts, other household appliances, applications, etc., can solve the problems of poor flexibility, short service life, and complicated production process of transmission belts, and achieve enhanced toughness, resistance to wear, and simple production process convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

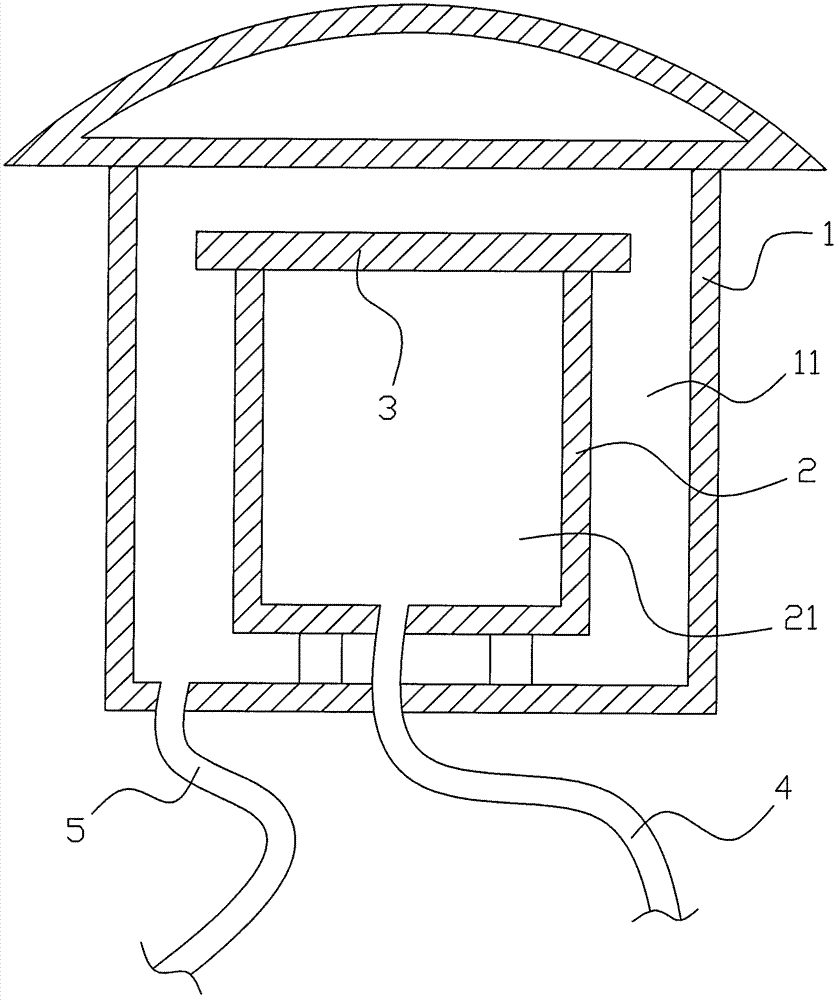

[0027] Embodiment one, such as figure 1 and figure 2 As shown, the basic composition of the transmission belt is: 0.05 parts of rubber, 0.002 parts of magnesium oxide, 0.0005 parts of stearic acid, 0.003 parts of zinc oxide, 0.002 parts of aromatic oil, 0.001 parts of polyethylene glycol, 0.0005 parts of paraffin, 0.02 parts of carbon black Parts, the above are parts by weight.

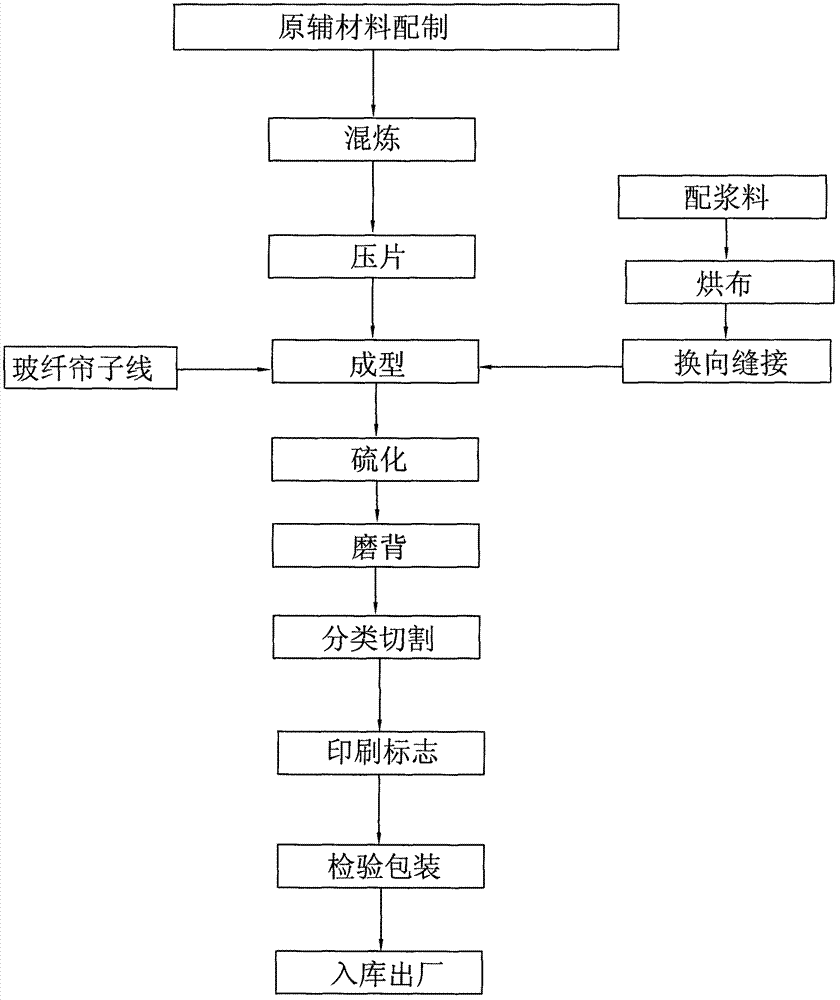

[0028] According to the manufacture method of the transmission belt of above-mentioned formula, comprises the following steps:

[0029] 1. Mixing, prepare the raw materials according to the formula of the above-mentioned transmission belt, then put the raw materials into the mixer and knead at room temperature, start kneading until uniform, and then discharge;

[0030] 2. Tablet pressing, the refined material is pressed into tablets by molding;

[0031] 3. Select pure cotton cloth, apply common slurry on the pure cotton cloth, and dry the cloth;

[0032] 4. Put the glass fiber cord between the up...

Embodiment 2

[0037] Embodiment two, such as figure 1 and figure 2 As shown, the basic composition of the transmission belt is: 0.055 parts of rubber, 0.0025 parts of magnesium oxide, 0.00055 parts of stearic acid, 0.0035 parts of zinc oxide, 0.0025 parts of aromatic oil, 0.0015 parts of polyethylene glycol, 0.00055 parts of paraffin, and 0.025 parts of carbon black. Parts, the above are parts by weight.

[0038] According to the manufacture method of the transmission belt of above-mentioned formula, comprises the following steps:

[0039] 1. Mixing, prepare the raw materials according to the formula of the above-mentioned transmission belt, then put the raw materials into the mixer and knead at room temperature, start kneading until uniform, and then discharge;

[0040] 2. Tablet pressing, the refined material is pressed into tablets by molding;

[0041] 3. Select pure cotton cloth, apply common slurry on the pure cotton cloth, and dry the cloth;

[0042] 4. Put the glass fiber cord b...

Embodiment 3

[0047] Embodiment three, such asfigure 1 and figure 2 The basic composition of the transmission belt is: 0.06 parts of rubber, 0.003 parts of magnesium oxide, 0.0006 parts of stearic acid, 0.004 parts of zinc oxide, 0.003 parts of aromatic oil, 0.002 parts of polyethylene glycol, 0.0006 parts of paraffin, and 0.03 parts of carbon black. is parts by weight.

[0048] According to the manufacture method of the transmission belt of above-mentioned formula, comprises the following steps:

[0049] 1. Mixing, prepare the raw materials according to the formula of the above-mentioned transmission belt, then put the raw materials into the mixer and knead at room temperature, start kneading until uniform, and then discharge;

[0050] 2. Tablet pressing, the refined material is pressed into tablets by molding;

[0051] 3. Select pure cotton cloth, apply common slurry on the pure cotton cloth, and dry the cloth;

[0052] 4. Put the glass fiber cord between the upper and lower pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com