Spreading and drying method for highly-flavored liquor distiller<,>s grains

A technology of Luzhou-flavor liquor and distiller's grains, which is applied in the field of brewing, can solve problems such as uneven temperature, low degree of automation, and uneven thickness of distiller's grains, so as to improve the uniformity and uniformity of the next song, and improve the uniformity of the cellar temperature , The effect of improving the uniformity of moisture in the cellar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

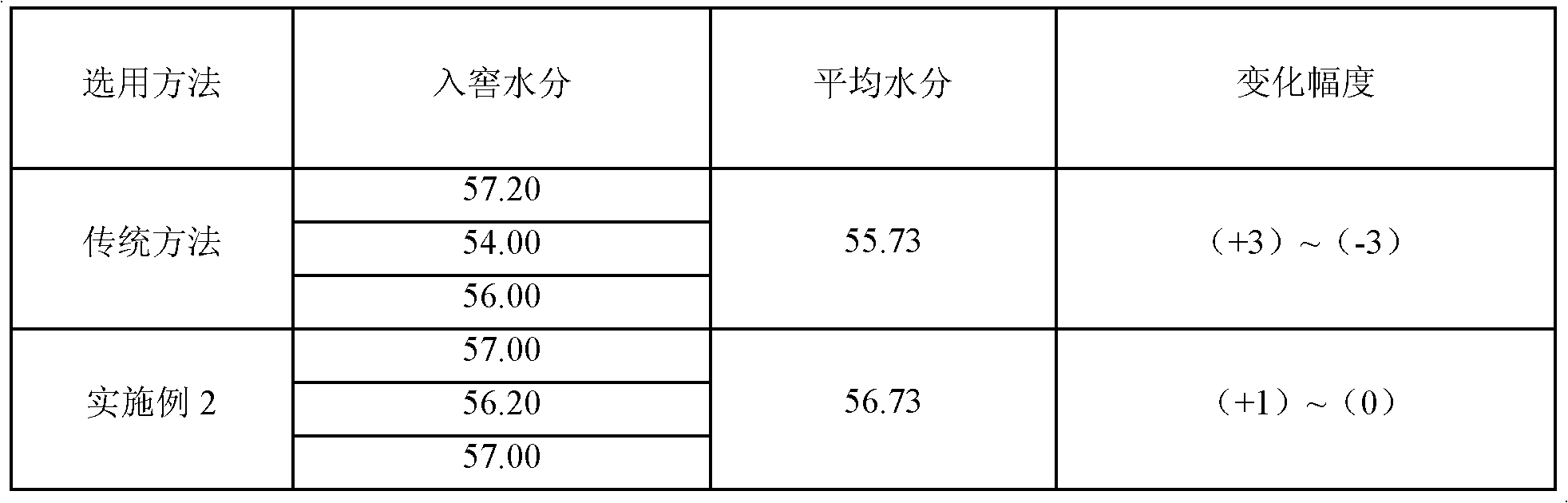

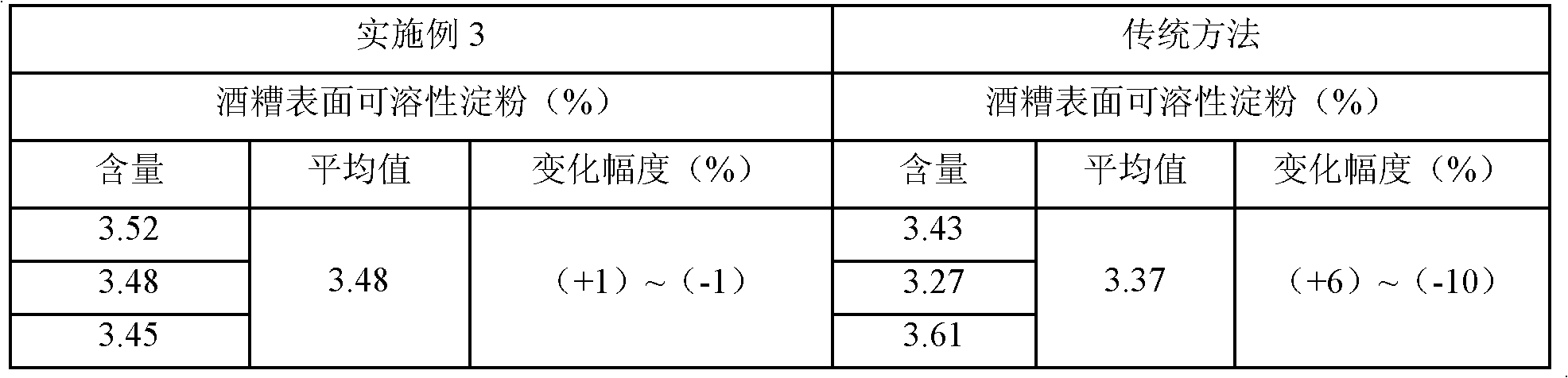

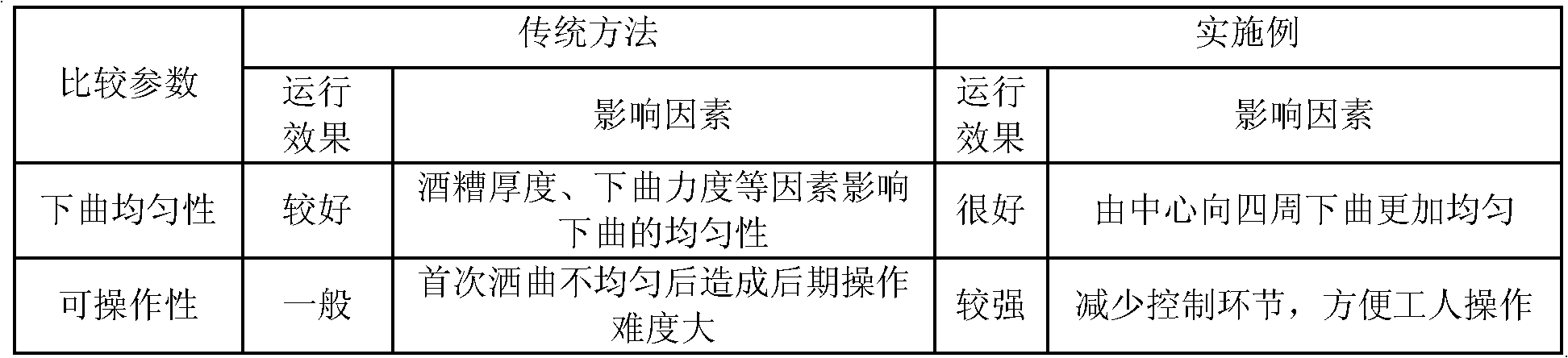

[0033] 4.8M 3 The distiller's grains are evenly divided into 2 wine retorts (2.4M 3 ) respectively adopt the traditional method and the air-drying method of the present invention to carry out comparative experiments, and measure indicators such as temperature uniformity of distiller's grains, moisture uniformity, soluble starch uniformity, and lower koji uniformity.

[0034] The specific method of embodiment 1 is: adopt the aforementioned steps a-i, wherein, in step c, after the distiller’s grains are moved into the drying grain bed, control the thickness of the distiller’s grains at 18 cm; Distiller's grains, cool the distiller's grains to 43°C; then turn on the stirring again, cool the distiller's grains to 33°C, turn off the stirring, and control the stirring rate to 11 rpm during the stirring process; On the surface of the bad bed, spread the koji medicine in the middle first, and finish it at one time; then spread the koji medicine in the middle evenly to both sides; Pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com