Pre-stressed concrete tubular pile mechanical splice and pre-stressed concrete tubular pile

A technology for concrete pipe piles and mechanical joints, which is applied to sheet pile walls, buildings, infrastructure engineering, etc., can solve problems such as complex processing, and achieve the effects of simple processing of connecting pins, good pullout resistance, and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Embodiments of the present invention will be described in detail below.

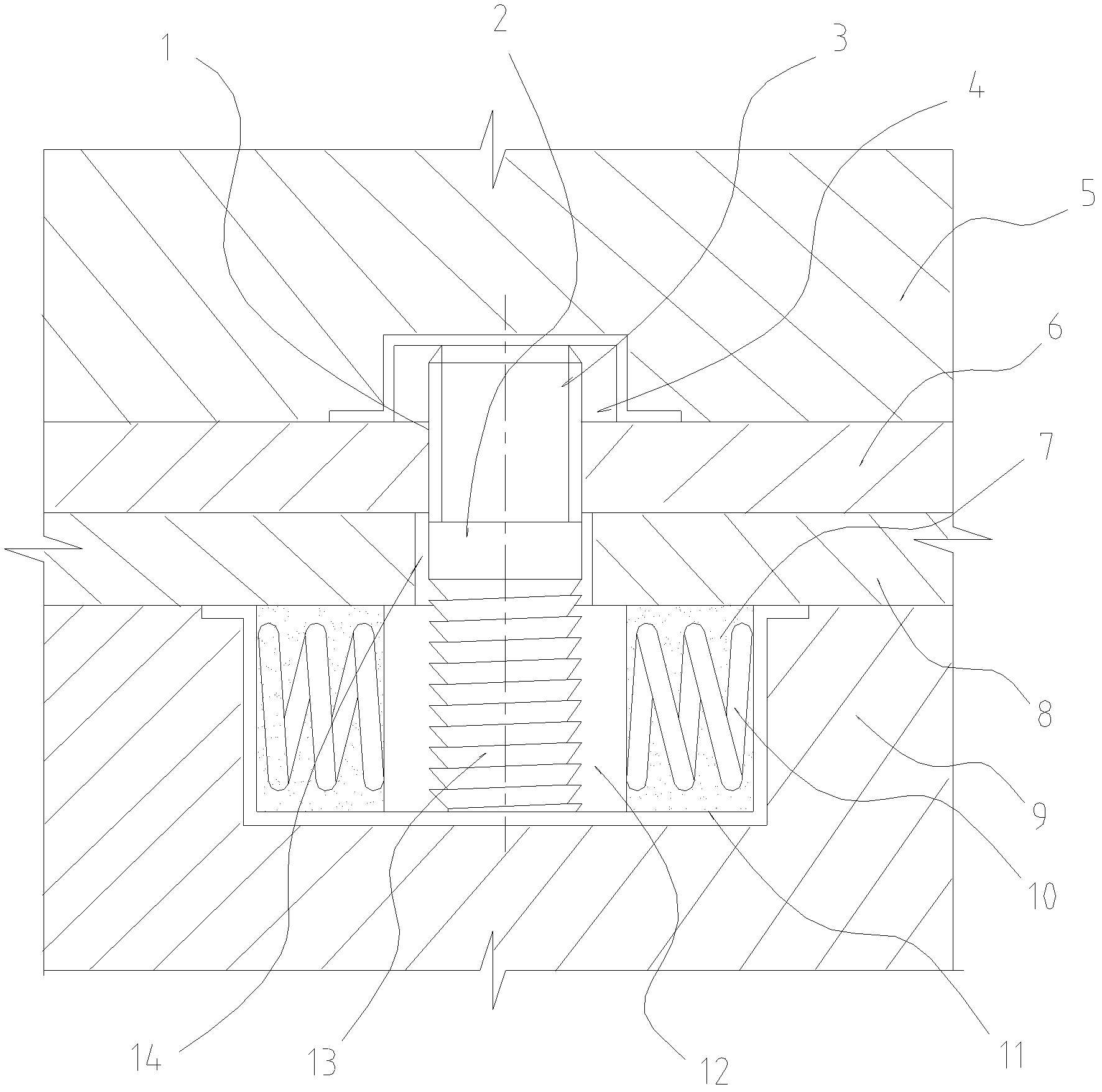

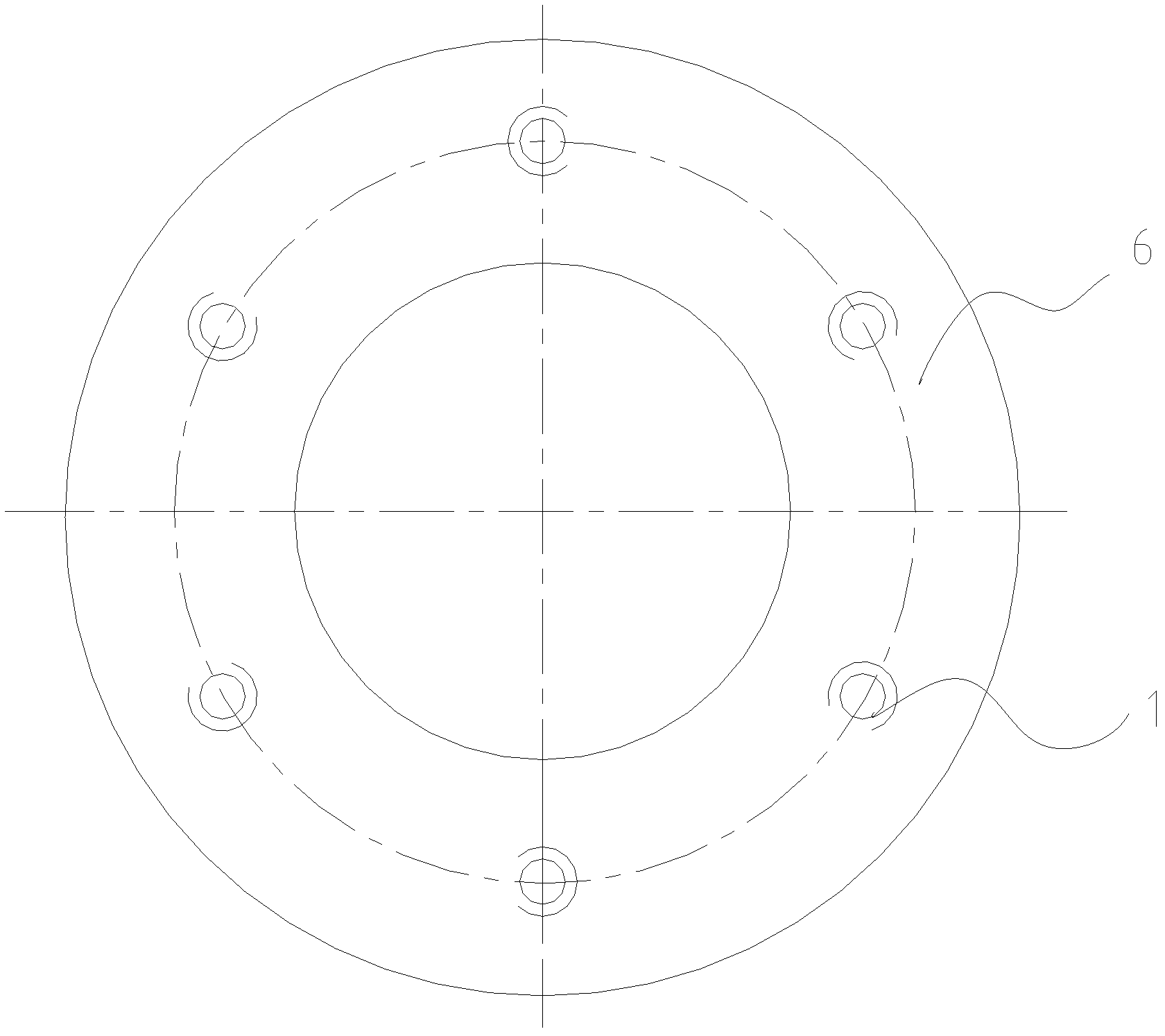

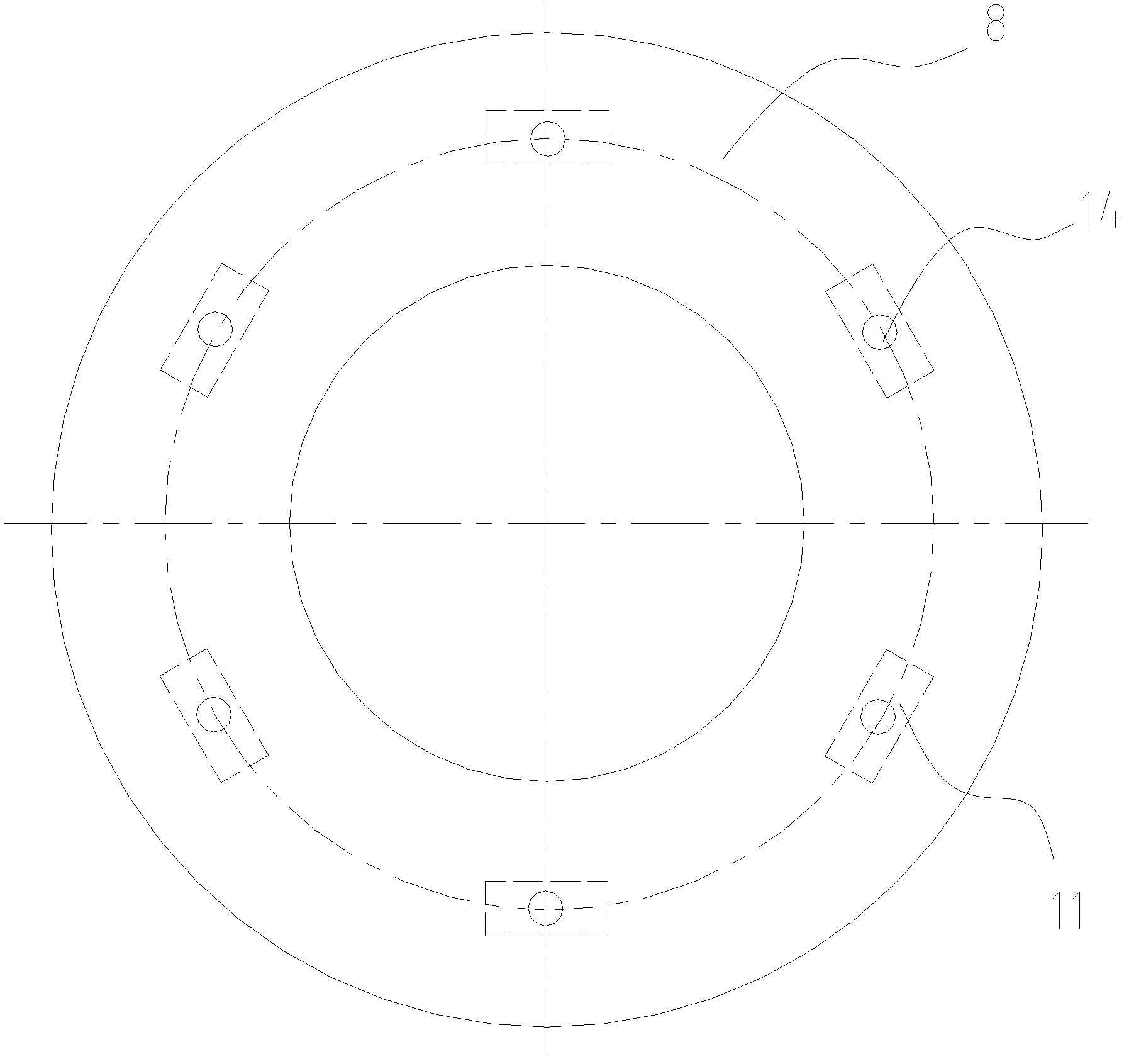

[0030] like Figures 1 to 5 As shown, the prestressed concrete pipe pile includes the first section pipe pile 5, the second section pipe pile 9, the first end plate 6, the second end plate 8 and mechanical joints, wherein the first section pipe pile 5 and the second section pipe pile The opposite surface of the section pipe pile 9 is the connection end, the first end plate 6 is fixedly connected with the connection end of the first section pipe pile 5, the connection end of the second end head plate 8 is fixed with the connection end of the second section pipe pile 9 Preferably, hole covers 4 corresponding to the threaded holes 1 one by one and opening opposite to the threaded holes 1 are buried at the connecting end of the first end plate 6 . Six circular through-holes 14 corresponding to the threaded holes 1 are provided on the second end plate 8, and there are embedded holes corresponding to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap