Sludge refluxing and flocculating precipitation tank

A sedimentation tank and sludge technology, applied in the field of flocculation sedimentation tanks, can solve the problems of unfavorable, unfavorable sludge and uniform diffusion of water treatment chemicals, achieve reasonable structure, improve flocculation reaction uniformity and reaction efficiency, and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

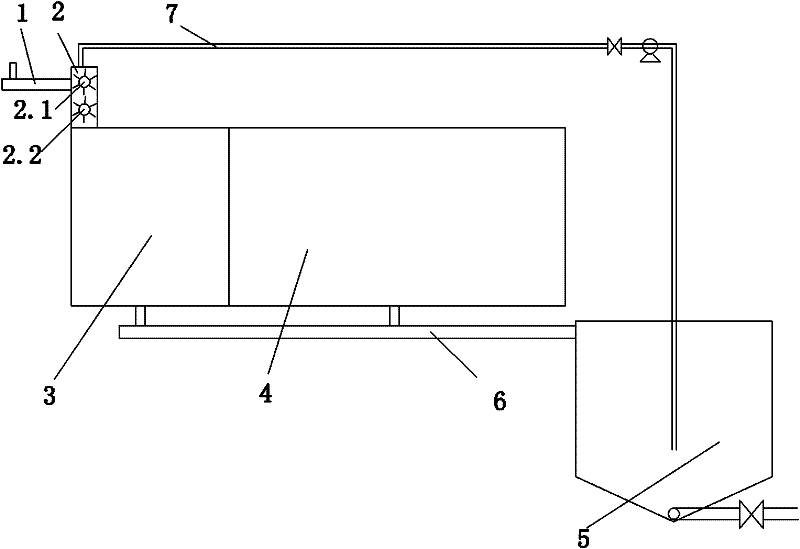

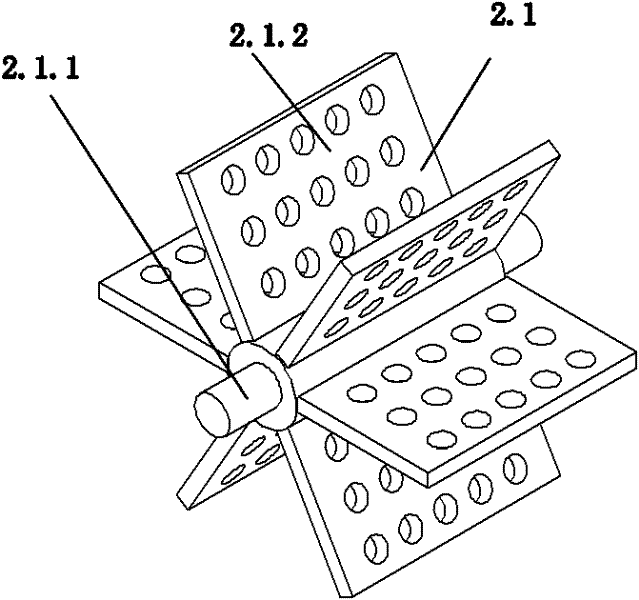

[0024] Such as figure 1 As shown, the present invention includes a pipeline mixer 1, a return sludge mixer 2, a multistage flocculation unit 3, a sedimentation unit 4, a sludge collection unit 5, a sludge collection piping system 6, and a sludge return piping system 7; The raw water inlet of the flocculation unit 3 is set at the top left end of the multi-stage flocculation unit 3, and the sludge collection unit 5 communicates with the bottom of the multi-stage flocculation unit 3 and the sedimentation unit 4 through the sludge collection piping system 6; the sludge return piping system 7 The sludge suction pipe is arranged in the sludge collection unit 5; the return sludge mixer 2 includes a return sludge mixer shell and a muddy water main mixing agitator 2.1 and a second muddy water mixer 2.1 rolled on the backflow sludge mixer shell. The mixing agitator 2.2, the structure and size of the second muddy water mixing agitator 2.2 and the muddy water main mixing agitator 2.1, th...

Embodiment 2

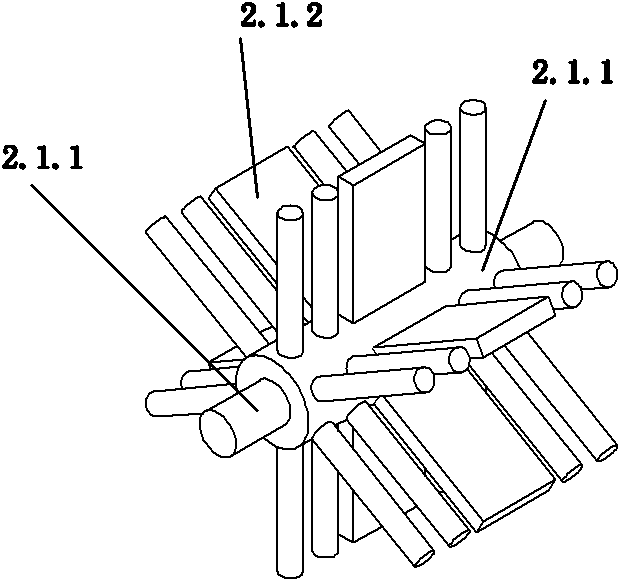

[0028] The first difference between the second embodiment and the first embodiment lies in the difference in the structure of the stirring hand 2.1.2 on the muddy water main mixing agitator 2.1. Such as image 3 As shown, each stirring hand 2.1.2 of Embodiment 2 is composed of a stirring plate in the middle and stirring round rods symmetrically distributed on both sides of the stirring plate. The impact of the chemical mixture and the return sludge drives the mud water main mixing agitator to rotate. This structure saves materials, the moment of inertia of the mud-water main mixing agitator is small, the rotation is easy, and the mixing effect is good.

[0029] The second difference between the second embodiment and the first embodiment lies in the structure of the pipeline mixer used. Such as Figure 5 and Figure 6 As shown, the pipeline mixer 1 includes a water inlet dosing area 1.1, a water medicine mixing area 1.2, a water outlet area 1.3 and an impeller installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com