Method and device for drawing a quartz glass cylinder from a melt crucible

A technology of quartz glass and melting crucible, which is applied in glass forming, glass forming, glass production, etc. It can solve the problems of sensitive temperature fluctuation, complicated design and operation, etc., and achieve the reduction of melting energy, improvement of homogeneity, and reduction of Effect of temperature load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

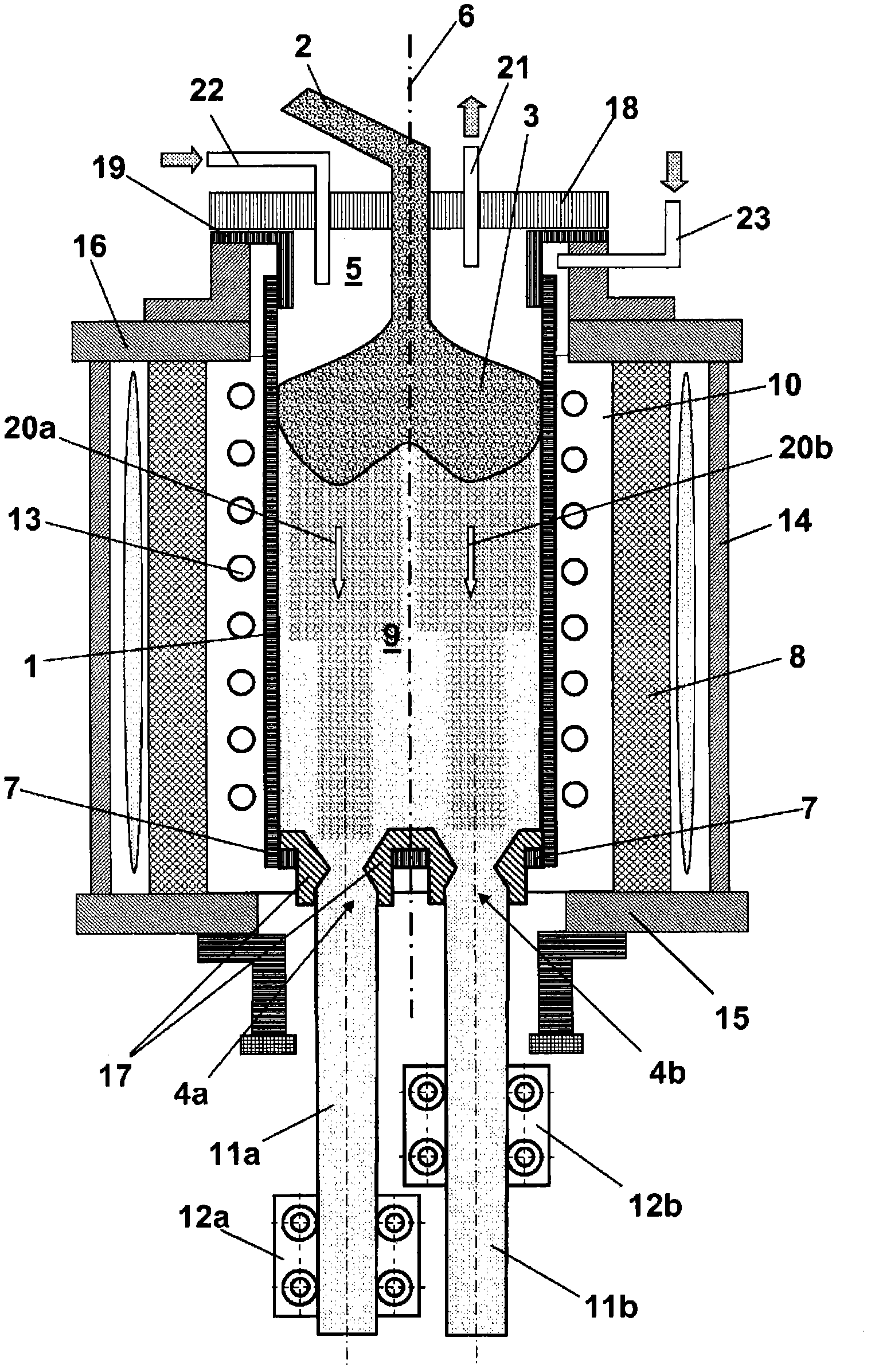

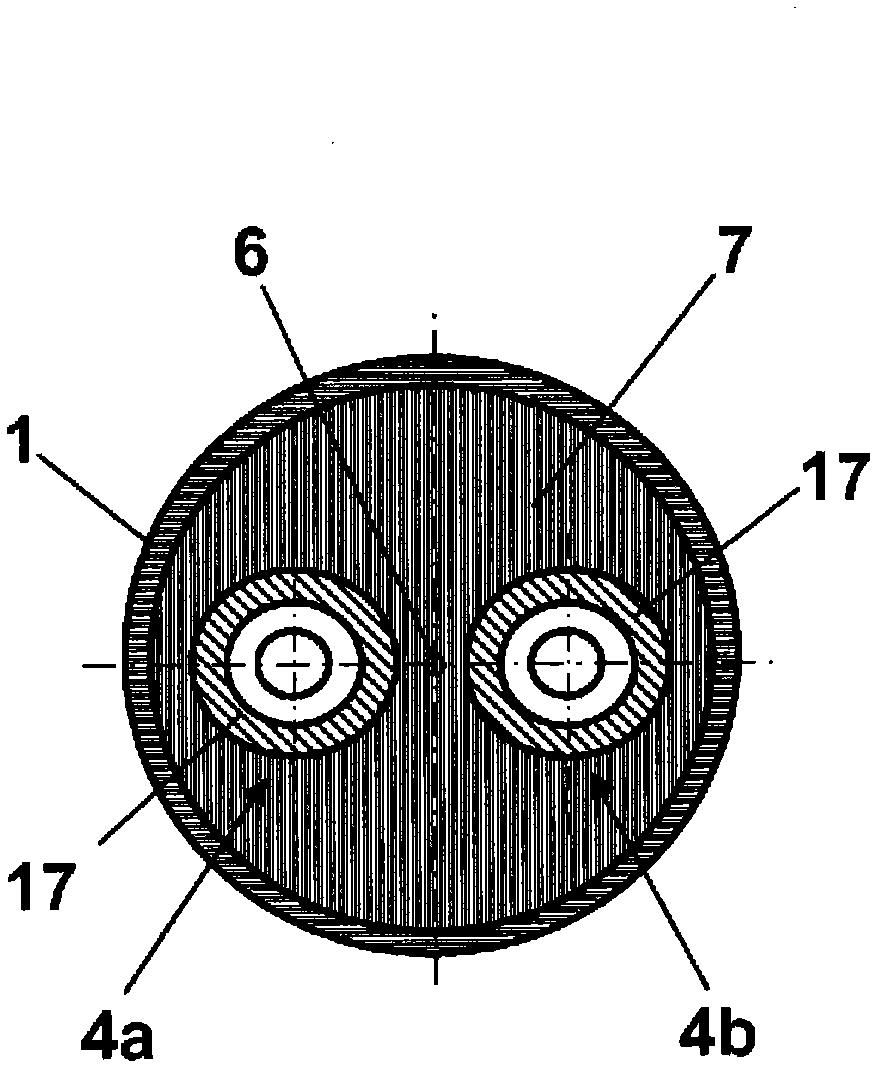

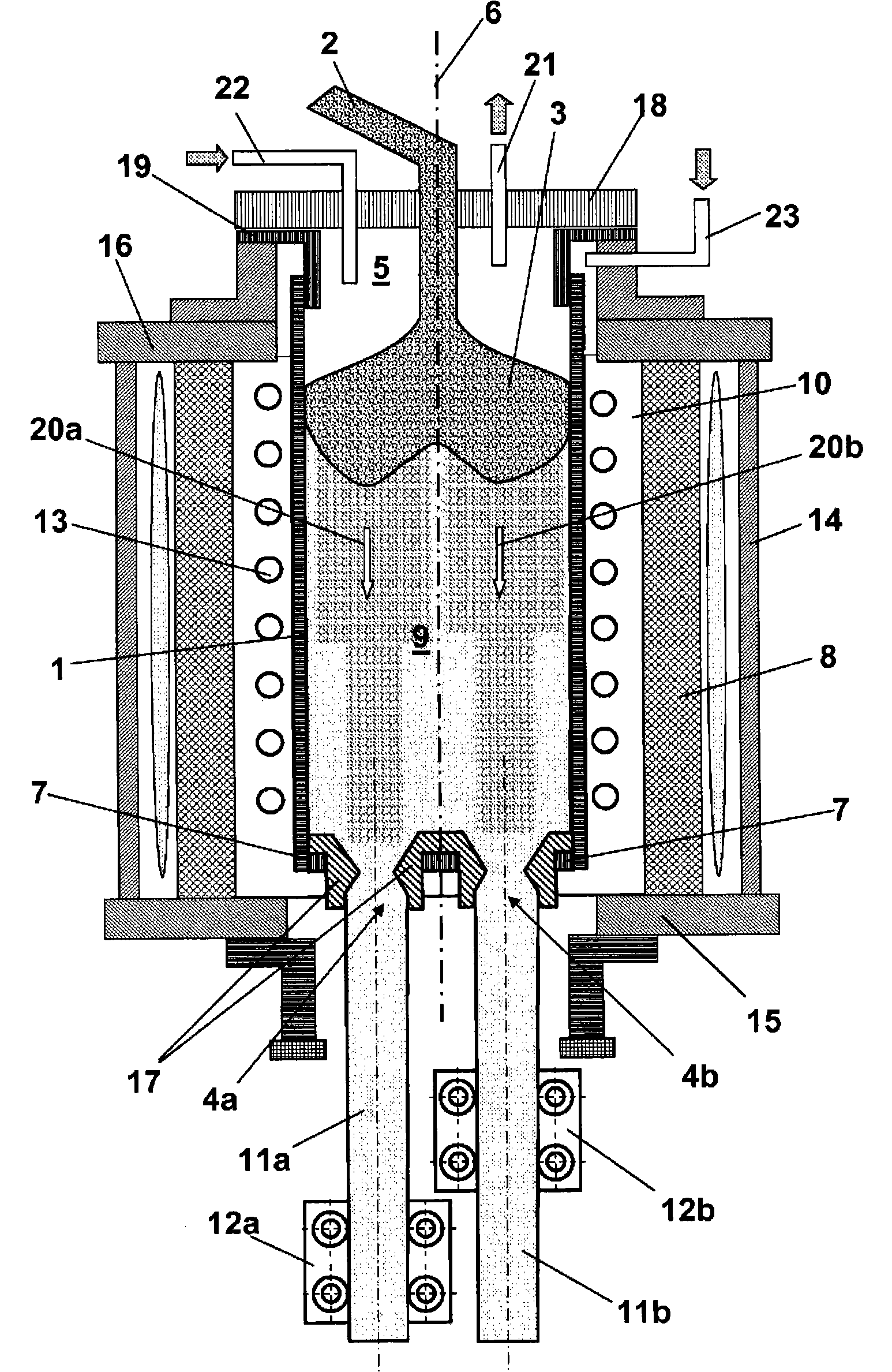

[0050] SiO 2 The particles 3 are conveyed continuously via the supply pipe 2 into the melting crucible 1 and heated therein to a temperature of approximately 2100° C. to 2200° C. Here, in the region of the lower part of the melting crucible 1, a softer quartz glass frit 9 is formed, on which the SiO 2 Particle layer composed of particles 3. from SiO 2 The particles 3 form two approximately equally sized main mass flows 20a, 20b with softened quartz frit 9 in the direction of the two drawing dies 4a, 4b. These main mass flows 20a, 20b are in figure 1 are shown by hatching and square arrows.

[0051] Since the quartz glass frit 9 is exposed to an average higher temperature in the region of the melting crucible 1 near the edges than in the middle region, it is therefore more effective in the two main mass flows near the edges than at a given melting crucible temperature. The situation in the middle area is better homogenized. The magazine flow through the melting crucible r...

example 2

[0053] Alternatively to this, SiO 2 The particles 3 are heated in the melting crucible 1 to a temperature of approximately 2050° C. to 2150° C., ie approximately 50° C. lower than in Example 1 .

[0054] Here, from SiO 2 The granule 3 is also formed in the direction of the two drawing dies 4 a , 4 b with two approximately equally sized peripheral main mass flows 20 a , 20 b of the quartz frit 9 .

[0055] Here, the quartz glass frit 9 in the main mass flows 20a, 20b is exposed to a temperature load approximately as in a "silo flow" in a conventional drawing method, and the solid cylindrical bundles 11a, 11b thus obtained thus have Approximately the same homogeneity as the intermediate bundle produced in conventional drawing methods. However, since the temperature load on the crucible wall 1 and the crucible bottom 7 is lower, less penetration of the crucible from wear (Abrieb) and other impurities into the softened quartz frit and a longer service life of the melting crucibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com