Process for preparing a polymer polyol

A technology for polyols and polymers, applied in the field of preparing polymer polyols, which can solve problems such as increased batch time and long batch time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Polymer polyols were prepared by applying the following batch process in which the following compounds were used:

[0027]Base polyol = polyether polyol comprising randomly distributed ethyleneoxy and propyleneoxy monomers in a weight ratio of about 11 / 89. It is produced by using glycerol as the initiator and potassium hydroxide (KOH) as the catalyst. The base polyol has a weight average molecular weight of about 3,000 and an OH value of about 54 mg KOH / g.

[0028] Styrene and acrylonitrile = ethylenically unsaturated monomers.

[0029] AMBN = azobis(2-methylbutyronitrile) (polymerization initiator).

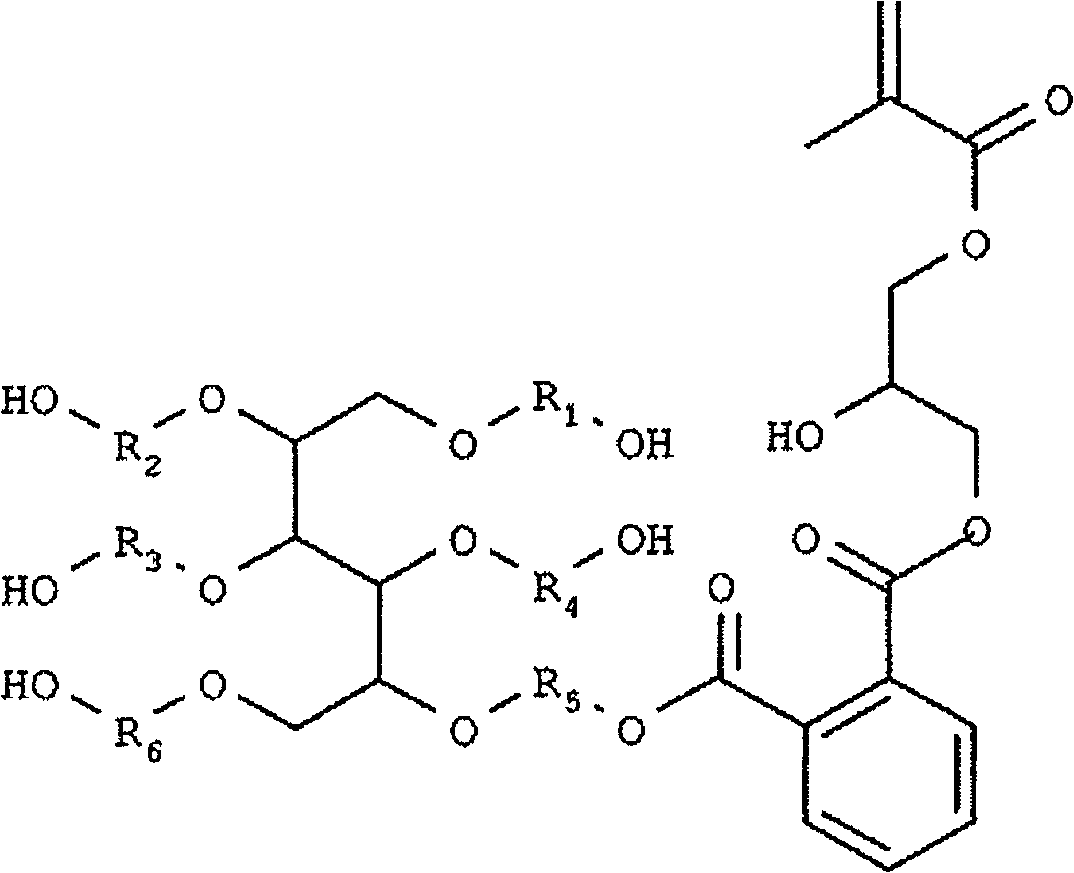

[0030] Macromonomer = polyol with the following structure (according to WO1999040144):

[0031]

[0032] where R 1 to R 6 Represents a chain comprising randomly distributed propylene oxide (PO) and ethylene oxide (EO) monomers. The weight ratio of PO to EO in these chains is about 82 / 18. The weight average molecular weight per chain (averaged over all six chains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com